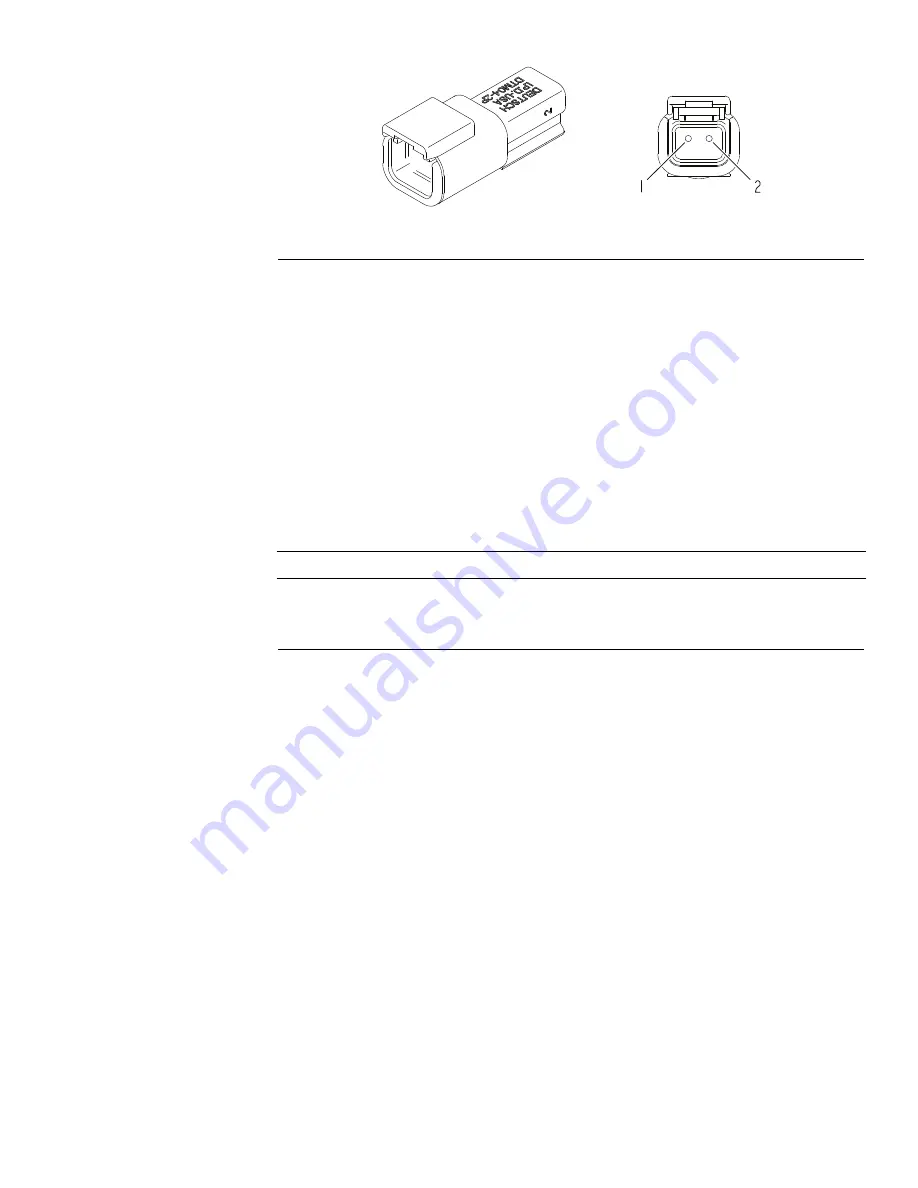

CAN-bus Terminator Resistor

g291761

Figure 64

The system communication between the electrical components on the

Greensmaster e1021/e1026 machines are accomplished on a CAN-bus

communication system. The 2 specially designed, twisted cables form the

bus for the networks used on the e1021/e1026. These wires provide the data

pathways between the machine components. At the ends of the twisted pair of

bus cables are 120 ohm terminator resistors.

The resistors plug into the wire harness in the following areas:

1. On the main wire harness under the key switch, inside the handle cover.

2. On the main wire harness near the TEC controller.

Note:

Refer to the Electrical Schematic and Wire Harness Drawings in

Appendix A (page A–1)

for additional information on the terminator resistor

locations and wire connections.

IMPORTANT

The terminator resistors at the ends of the bus cables are required

for proper electrical system operation.

Testing the CAN-bus Terminator Resistor

1. The CAN-bus terminator resistor (

) can be tested using a digital

multimeter (ohms setting). Locate the CAN-bus terminator resistor and

remove the cable tie that secures the resistor to the wire harness. Unplug the

resistor from the wire harness for testing.

2. Check the resistor and resistor holder for damage or corrosion and clean

or repair if necessary.

3. Use a digital multimeter (ohms setting) to measure the resistance value for

the CAN-bus terminator resistor. There should be 120 ohms resistance

between the terminals 1 and 2.

4. If the testing determines that the CAN-bus terminator resistor is damaged,

replace the CAN-bus terminator resistor.

5. After you complete the testing, ensure that the CAN-bus terminator resistor

is fully installed into the wire harness connector and secured to the wire

harness with cable tie.

6. If the resistor test correctly and a circuit problem still exists, check the

CAN-bus; refer to

Testing the CAN bus (page 5–24)

, wire harness drawings

in

Appendix A (page A–1)

for additional information, or contact an Authorized

Toro Distributor for assistance.

Greensmaster

®

e1021/e1026

Page 5–39

Electrical System: Testing the Electrical Components

20246SL Rev A

Содержание 04831

Страница 4: ...NOTES NOTES Page 4 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 6: ...g340650 Figure 1 Model 04831 shown Preface Page 6 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 14: ...Safety Safety and Instructional Decals Page 1 6 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 46: ...Troubleshooting Battery Charger Error and Fault Codes Page 3 14 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 136: ...Electrical System Service and Repairs Page 5 56 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 162: ...Controls Wheels and Accessories Service and Repairs Page 6 26 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 210: ...Universal Groomer Optional Service and Repairs Page 8 20 Greensmaster e1021 e1026 20246SL Rev A ...

Страница 213: ...Greensmaster e1021 e1026 Drawing 122 1647 Rev A Sheet 1 of 1 20246SL Rev A Page A 3 Electrical Schematic g361655 ...

Страница 214: ...Page A 4 20246SL Rev A Greensmaster e1021 e1026 Drawing 122 1734 Rev D Sheet 1 of 2 Wire Harness Drawing CV g361656 ...

Страница 215: ...Greensmaster e1021 e1026 Drawing 122 1734 Rev D Sheet 2 of 2 20246SL Rev A Page A 5 Wire Harness Drawing g361657 ...

Страница 216: ......