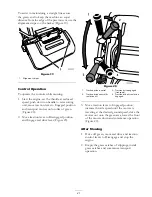

Figure 42

1. Tang washer

2. Idler bracket bolt

B. Using a 3/8 inch drive torque wrench,

rotate the idler bracket with 35-40 in.-lb. of

torque to set the belt tension (Figure 43).

While holding the torque wrench setting,

tighten the idler bracket mounting bolt

(The tang washer is installed to prevent the

belt from slipping.). Do not over-tension

the belt.

Figure 43

1. Traction drive belt

3. 3/8 inch Torque wrench

here

2. Idler bracket

C. Install the belt cover.

Controls System

Maintenance

Adjusting the Traction

Control

If traction control does not engage or it slips

during operation, an adjustment is required.

1. Move traction control to Disengaged position.

2. To increase cable tension, loosen front cable

jam nut and tighten back cable jam nut

(Figure 44) until a force of 12-16 lb. is required

to engage traction control.

Measure the force at the control knob.

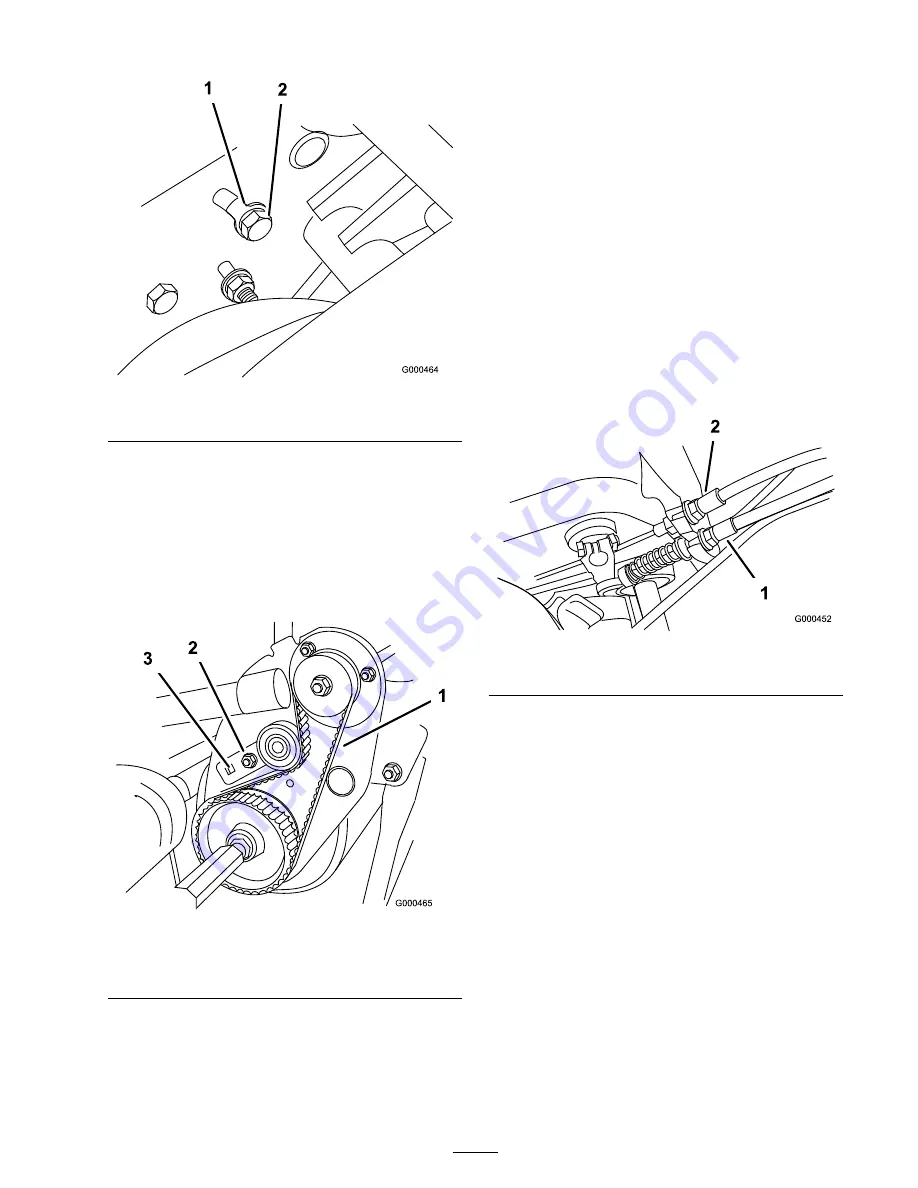

Figure 44

1. Traction cable

2. Service/parking brake cable

3. Tighten front cable jam nut.

4. Check control operation.

Adjusting the Reel Control

If reel control does not engage or it slips during

operation, an adjustment is required.

1. Make sure traction control is properly adjusted;

refer to Adjusting the Traction Control.

2. To increase cable tension, loosen front cable

jam nut and tighten back cable jam nut

(Figure 45) (located on top of gear box)

until the reel cable force adds 7 to 10 lbs. of

additional handle force measured at the control

knob.

Note:

If traction control handle force is

12 lbs., the combined traction and reel force

should be 19 to 22 lbs.

31