13

Height-of-Cut Adjustment for a

Fixed Cutting Unit

1. Adjust reel to bedknife contact.

2. Loosen nuts securing skids or front roller and raise to

highest position.

3. Loosen jam nuts securing rear roller. Lower roller

beyond desired height-of-cut (ensures proper bedknife

attitude).

4. Lower cutting unit onto a flat surface, such as a 1 in. x

20 in. x 30 in. piece of plywood. Shut off engine and

remove the key.

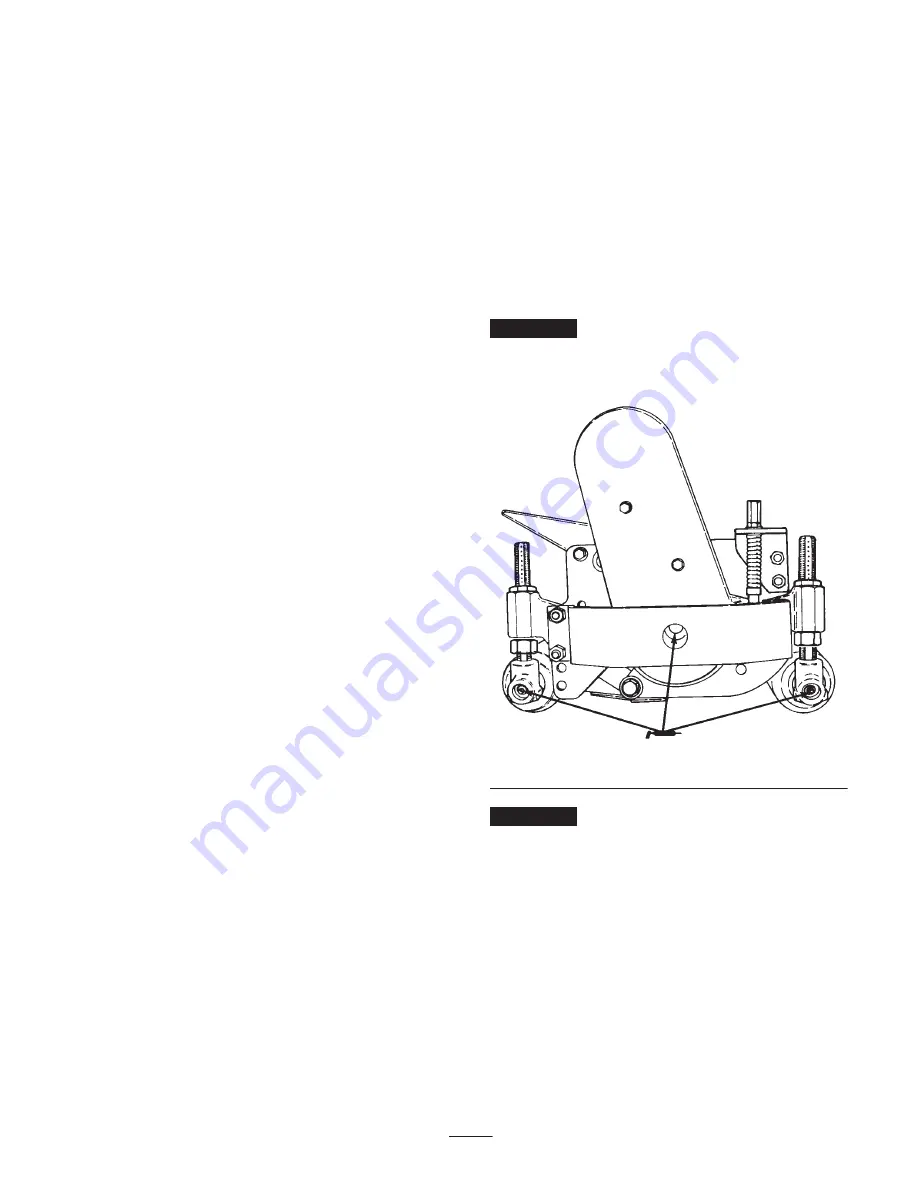

5. Insert piece of bar stock (Fig. 16) 25–28 in. (70 cm)

long with thickness equal to desired height-of-cut,

under entire length of the reel, next to bedknife.

6. Adjust rear roller adjustment knobs and jam nuts until

full length of the rear roller contacts the flat surface

and the full length of the reel (not bedknife) contacts

the bar stock. Tighten rear roller knobs and jam nuts.

Adjusting the Skids and Front

Roller (Fixed Head Kit)

After skid kit or front rollers are installed (installation

instructions are included with each option) make the

following adjustments to prevent them from pushing down

uncut grass or scalping on undulating terrain:

1. Lock each cutting unit in the fixed position (Refer to

Cutting Unit Orientation, Fig. 15). Set the reel to

bedknife adjustment and height-of-cut adjustment.

2. Position the cutting units on a flat, level surface (1 in.

(25 mm) thick piece of plywood).

3. Skids and front rollers used to prevent scalping should

not ride on the ground. Adjust each skid or front roller

so it is 1/8–1/4 in. (3–6 mm) or higher above the level

surface. Allow greater clearance at the higher

height-of-cut settings.

4. Proper adjustment is achieved when the cutting unit

does not scalp the grass in normal mowing conditions

and yet is set high enough not to mar the turf and

create undue wear on the skids or rollers.

Note: Skids are used only with the cutting unit in the

fixed position. Front rollers may be used with the cutting

unit in either the fixed or floating position.

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Lubrication

Before and after greasing, wipe each grease fitting with a

clean rag. Use a hand-operated grease gun and #2 general

purpose grease to lubricate the eight grease fittings.

Applying too much pressure will ruin the seals and

leaking grease could cause damage to grass.

Important

Before washing the machine, shut off the

engine and remove the key. Lubricate the reels and rollers

immediately after washing the machine. This helps to

minimize water entering the reel and roller bearings.

Figure 22

Important

If the cutting units are washed in the raised

position, be sure to lower them to the ground after

washing. This allows water to drain from the ends of the

rollers and reel bearing housings.

1. Lubricate the reel shaft and roller bearings with 3 or 4

pumps of grease. Daily lubrication of these fittings

purges water and other contaminants, increasing

service life and maintaining excellent quality-of-cut.

Note: When greasing roller bearings, grease forced from

bearings will not be visible around the roller shaft.