17

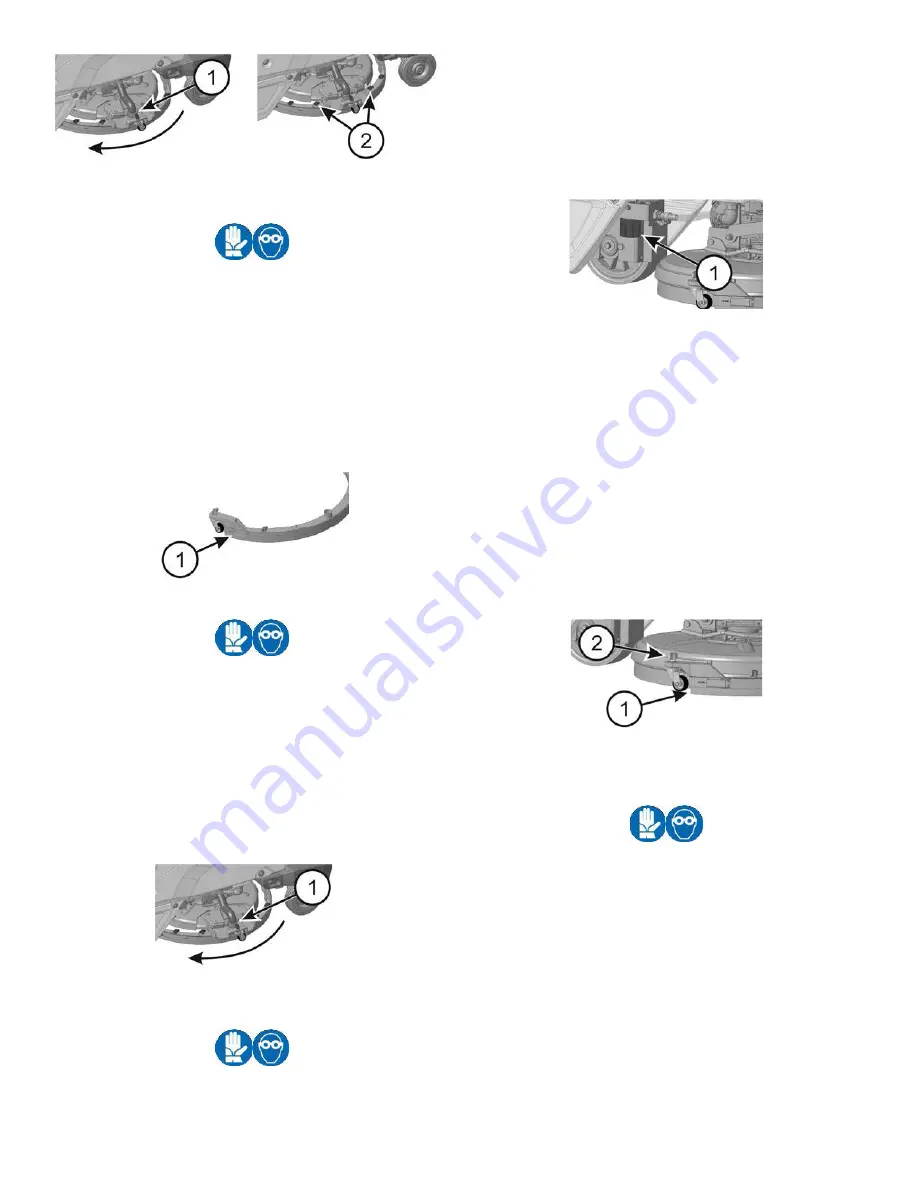

The squeegee height has to be adjusted

depending on how much the rubbers are worn.

In order to obtain an optimal drying, the lower

edge of the rear squeegee rubber (1) must be

slightly bent backward along all its length.

To adjust the rubber bending proceed as

follows:

Loose the knob (2) for each wheel that

you want to adjust. Turn the wheel ferrule

clockwise in order to decrease the bending or

counterclockwise to increase the bending of

the rubber. Lock the knob keeping the ferrule

steady.

WEEKLY MAINTENANCE

REAR SQUEEGEE RUBBER CHECK

Check the squeegee rubber wearing and

eventually turn it or replace it.

For the replacement it is necessary:

1. Take off the squeegee (see chapter

“CLEANING THE SQUEEGEE”).

2. Unlock the squeegee blade lock (1).

3. Take off the rubber to turn it around or

replace it.

To put back the squeegee just repeat these

operations backwards.

CLEANING THE SQUEEGEE HOSE

Weekly or in case of insufficient suction, it is

necessary to check that the squeegee hose is

not obstructed. Eventually, to clean it, proceed

as follows:

1. With the brush base lifted, rotate the

squeegee on one side.

2. With the squeegee in such position, take off

the squeegee hose coupling (1).

Do not wash the hose that goes from the

suction motor to the recovery tank.

CLEANING THE OUTER FILTER AND THE

SOLUTION TANK

Take the machine to the place assigned for the

detergent solution draining.

1. Unscrew the filter cap (1) and take the filter

out.

2. Wash the filter components with a water jet.

Once finished, close the valve, reassemble the

filter and replace the tank cap.

SQUEEGEE HEIGHT ADJUSTMENT

TWO-MONTHLY MAINTENANCE

FRONT SQUEEGEE RUBBER CHECK

Check the wear of the squeegee rubber and

eventually replace it.

For the replacement it is necessary to:

1. Take off the squeegee (see under paragraph

“SQUEEGEE CLEANING”).

2. Disassemble the rear part of the squeegee

(see under paragraph “REAR SQUEEGEE

RUBBER CHECK”).

3. Unscrew the wing nuts (1) and take off the

front rubber holder blade (2).

4. Replace the front rubber (3).

To reassemble the squeegee repeat backwards

the operations above mentioned.

Содержание BDSO 20/21

Страница 21: ...21 TS120 S59 U...