15

3S “SOLUTION SAVING SYS-

TEM” (OPTIONAL)

The need of an increasing

carefulness to the environment,

and to the abuse of polluting

elements, such as detergents

in the floor cleaning machines,

has brought us to the realiza-

tion of a device which, regard-

less from the capacity to use

the machine by the operator,

keeps the minimum flow of the

detergent solution constant,

having been properly calibrated

by an expert technician. The

best detergent solution amount

with this system will be the one

which realizes the minimum flow

of detergent solution sufficient

to clean correctly the floor. For

this reason the system is called

“Solution Saving System” ab-

breviated to “3S”.

The system is composed of a

hydraulic circuit parallel to the

traditional one which can be en-

abled or disabled directly from

the instrument board through a

3-position switch with the follow-

ing functions:

(1) = Position solution valve

with traditional functioning with

variable water flow that differs

by the opening of the solution

valve.

(2) = Position STOP No solution

flow (drying only).

(3) = Position 3S with function-

ing with optimal fixed flow.

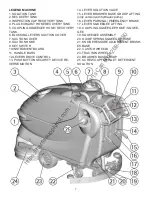

STARTING OF THE MACHINE

1. Turn the key (9) clockwise.

2. Check the battery type and

the charge level on the display

(1).

3. Press the brushes motor

switch (6).

4. Press the suction motor

switch (3).

5. Press the solenoid valve

switch (5).

6. Lower the brushes base onto

the floor.

The machines which have the

electrical brushes base lifting

press the push button (7) of up/

down of the brushes base.

7. Acting upon the solution valve

lever (14) open and adjust the

detergent solution flow.

The water starts to flow auto

-

matically acting upon the levers

drive control (12). On the instru-

ment board the indicator of the

solenoid valve switch (5) will

turn on. Releasing these levers,

will stop the flow.

Models equipped with the 3S,

(optional), it is necessary to

press the suitable switch to

activate the detergent solution

supply by choosing between the

traditional adjustment system

through the solution valve or the

system of fixed optimum sup

-

ply (see under “3S SOLUTION

SAVING SYSTEM”).

8. Acting upon the squeegee lift-

ing lever (17) lower the squee-

gee.

9. Acting upon the levers drive

control (12) the machine starts

to move, the brushes start to

rotate and the squeegee starts

to dry.

10. During the first metres

check that the squeegee ad-

justment guarantees a perfect

drying action and that the deter-

gent solution flow is appropri

-

ate. It has to be sufficient to wet

the floor uniformly avoiding the

leakage of detergent from the

splash guards. Always consider

that the correct quantity of solu-

tion detergent depends on type

of floor, dirtiness and machine

speed.

FORWARD MOVEMENT

The traction of the machine is

given through an electronically

controlled motor.

To move the machine, act upon

the key (9) and then rotate the

levers drive control (12) placed

on the handle bar, in forward

you obtain the forward drive, in

reverse the backwards move-

ment is obtained. The control

acts in a progressive way, there-

fore it is possible to graduate

the speed depending on each

requirement rotating the lever

whatever it is necessary. Dur-

ing reverse motion the speed is

reduced.

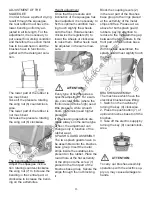

SPEED ADJUSTMENT

Two values of the maximum

drive working speed in forward

movement can be chosen.

Set the wanted speed through

the speed selection switch (2).

https://harrissupplyind.com - To Order Parts Call 608-268-8080