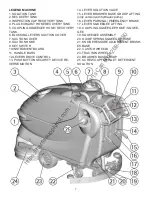

14

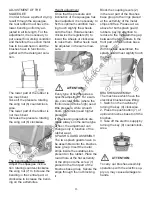

With the brushes base group in

lifted position, insert the brushes

into their plate seat underneath

the brushes base turning them

until the three metal buttons are

properly seated in their slots;

quickly rotate the brushes to

push the button towards the

coupling spring until they get

blocked.

The figure shows the rotating

sense for brushes coupling.

For a longer life of the brushes

we suggest to invert daily their

position. Whenever brushes are

deformed we suggest to reas-

semble them in the same posi-

tion, avoiding that the different

inclination of the bristles causes

excessive motor overload or

troublesome vibrations.

ATTENTION:

Use only brushes supplied with

the machine or the ones indicat-

ed in the paragraph “RECOM-

MENDED BRUSHES”. The use

of other brushes can compro-

mise security.

FLOOR CLEANING

CONNECTION OF THE BAT-

TERIES TO THE MACHINE

Once that the battery recharging

has been completed:

1. Disconnect the connector

(3) of the battery recharger (1).

To do this, it is necessary to

reach the battery compartment

as indicated under paragraph

“ACCESS TO THE BATTERY

COMPARTMENT”.

2. Connect instead the machine

connector (2).

3. Close the battery compart-

ment.

RECOVERY TANK

Check that the cover of the

suction filter (1) is correctly se

-

cured, after rotating the levers

(2) and that the suction motor

hose (3) is correctly connected

to it.

Verify also that the squeegee

hose couplings (4) are correctly

inserted into the seats, that the

exhaust hose plug (5) placed in

the front part of the machine is

closed and the inspection cap

(6) is closed well.

DETERGENT SOLUTION

TANK

The capacity of the detergent

solution tank is indicated in the

technical data.

Open the screw plug placed

in the rear left part of the ma-

chine and fill the solution tank

with clean water at a maximum

temperature of 122°F (50°C).

Add the liquid detergent in the

percentage and conditions fore-

seen by the manufacturer. To

avoid excessive foam presence,

which could cause problems to

the suction motor, use the mini-

mum percentage of detergent.

Screw down the plug to close

the tank.

ATTENTION:

Always use low foam detergent.

To avoid foam presence, be-

fore starting working operation,

introduce into the recovery tank

a minimum quantity of anti-foam

product.

Never use pure acid.

https://harrissupplyind.com - To Order Parts Call 608-268-8080