5

PREPARATION

DESCRIPTION

WARNING:

This Product contains chemicals known to

the state of California to cause cancer and birth defects or

other reproductive harm.

OPERATING INSTRUCTIONS

Before use (refer to Fig 1)

1. Verify that the product and the application are

compatible. If in doubt, contact Customer Support.

2. Before using this product, read the owner’s manual

completely and familiarize yourself thoroughly with the

product and its components, and recognize the hazards

associated with its use.

3. To familiarize yourself with basic operation, use the

stamped end of the provided handle to engage and

turn the release valve:

a. Clockwise until firm resistance is felt to further thread

engagement. This is the ‘CLOSED’ release valve

position used to raise the load.

b. Counterclockwise, but no more than ½ turn from the

closed position. This is the ‘OPEN’ release valve

position used to lower the load.

4. Check that the pump operates smoothly and that the

extension screw will thread up/down easily before

putting into service. Replace damaged or missing parts

with factory authorized replacement parts only. Only the

handle assembly, oil filler plug, label, and owners

manual are available for this jack. Repair of this product

may require special skills and knowledge and should

only be attempted by a factory authorized service center.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

Lifting

1. Place vehicle in park with emergency brake on and

wheels securely chocked to prevent inadvertent vehicle

movement.

2. Locate and close release valve by turning handle

clockwise until firm resistance is felt to further thread

engagement. Center jack saddle under lift point.

3. Verify lift point, insert handle into handle sleeve and

pump to contact lift point. To lift, pump handle until load

reaches desired height.

4. Transfer the load immediately to a pair of appropriately

rated jack stands.

Use only the handle assembly provided by the jack

manufacturer. The handle assembly provided with

this jack will safely engage the release valve and

operate the handle sleeve. If the handle is worn,

operates abnormally, or will not positively engage

the release valve, STOP. Discontinue use of the

jack until a factory replacement handle assembly

can be acquired.

Lowering

1. Raise load high enough to clear the jack stands; then,

carefully remove jack stands.

2. Slowly turn the handle counterclockwise, but no more

than a ½ turn. If the load fails to lower:

a. Use another jack to raise the vehicle high enough to

reinstall jack stands

b. Remove the affected jack and then the stands.

c. Using the other jack, lower the load by turning the

operating handle counterclockwise, but no more

than a ½ turn.

3. After removing jack from under the load, push saddle

down to reduce ram exposure to rust and contamination.

Model

T92007AT

features a

40,000

- lb. maximum capacity.

The jack features an overlad valve bypass system to

prevent jack damage and user injury.

Maximum Load Capacity......................20 tons (40,000-lb.)

Minimum Lifting Height............................................6

⅝

inch

Maximum Lifting Height.......................................10 inch

15

16

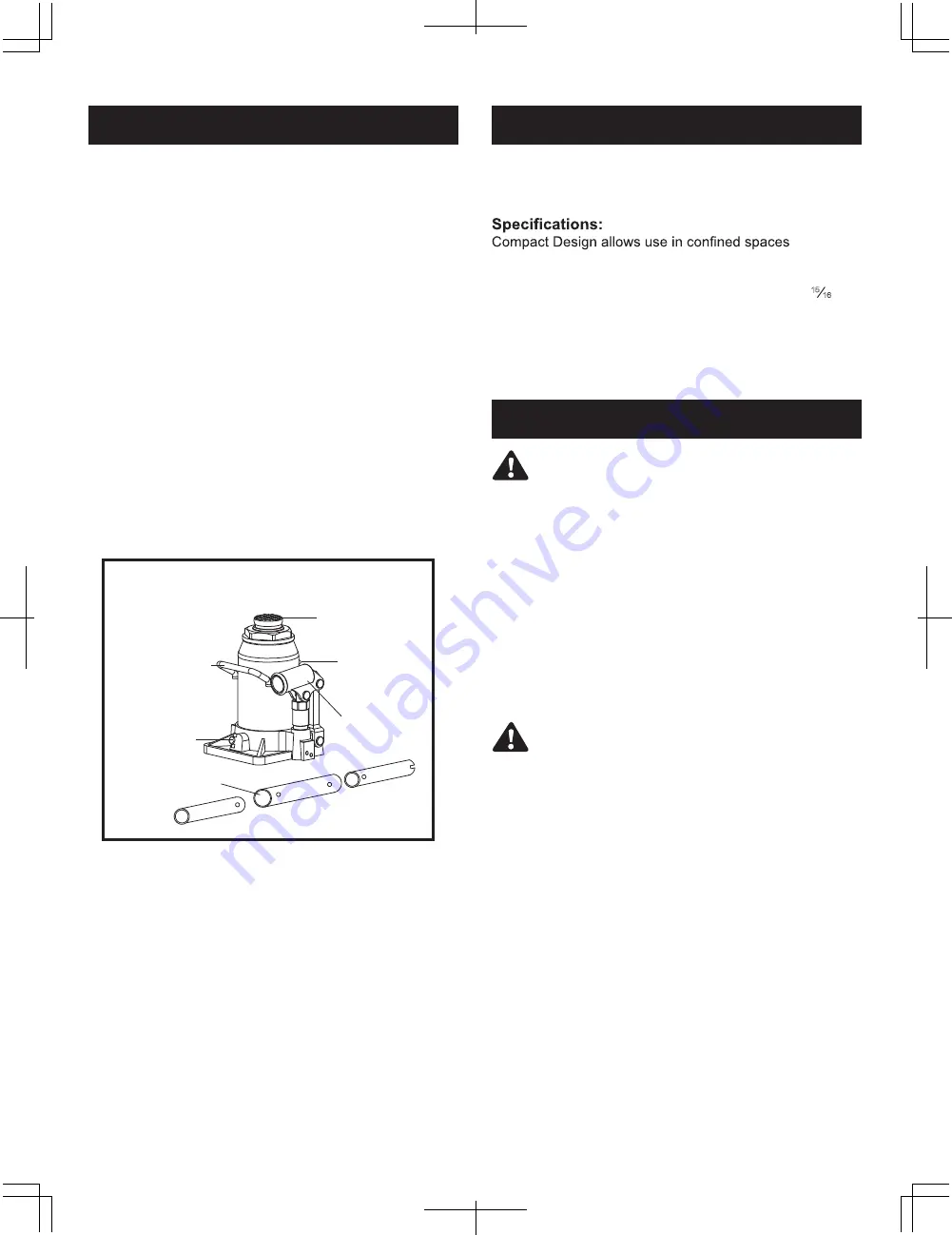

FIGURE 1 - Typical Bottle Jack

saddle

oil filler plug

(on reservior)

carry handle

(on selected

model only)

release valve

handle

sleeve

handle assembly

Содержание T92007AT

Страница 7: ...7...