20 І 160

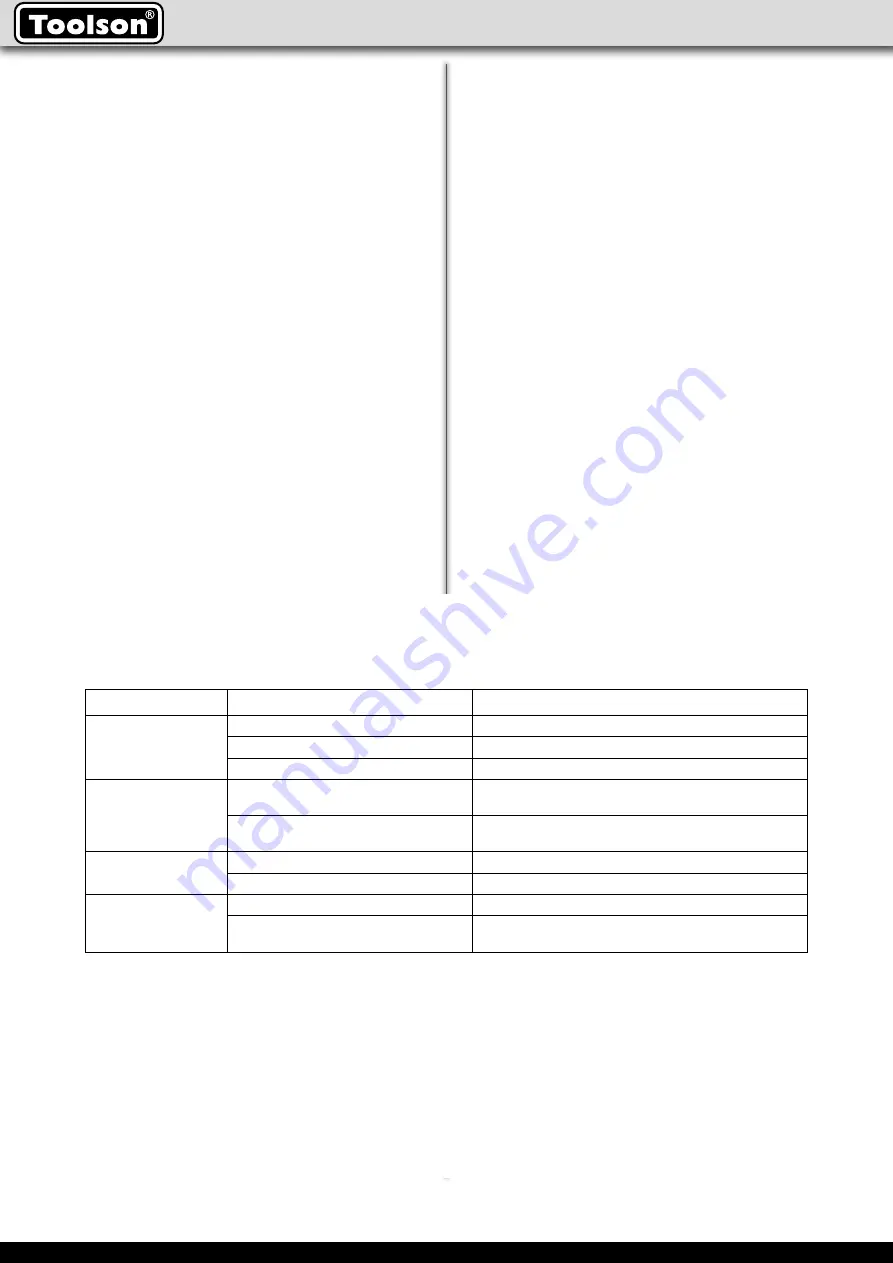

Troubleshooting

Supposed malfunctions, errors or damages are often caused by events which can be remedied by the operator. Therefore

check the power tool on the basis of the following table before you contact a specialist. Many malfunctions may thus be re-

medied.

Problem

Possible cause

Approach

1. Power tool does not

start

Power supply interrupted

Check power supply by connecting another power tool

Power cord or plug defective

Have an electrician check the tool

Other electrical defect of the power tool

Have an electrician check the tool

2. Power tool does

not operate with full

power

Extension cord too long and/or cross-

section too small

Use extension cord with permissible length and/or

adequate cross-section

Power supply (e.g. generator) voltage

too low

Connect power tool to an appropriate power supply

3. Poor operation

results

Power tool worn out

Replace insertion tool

Grinding plate worn out

Have grinding plate replaced

4. Considerable dust

formation

Brush edge worn out

Have brush edge replaced

Dust extraction not connectred /

switched on

Connect / switch dust extraction

Storage and transport

1. Whenever you do not use the power tool, you must

keep it in a dry and weil ventilated place out of the

reach of children, e.g. on a high cabinet or in a

closed place.

2. Keep power tool, instruction manual and accesso-

ry parts, if any, together in the original packaging,

if possible. Thus you have all information and parts

available at any time.

3. Always hold the power tool by its handle.

4. To avoid transport damages, you must pack the po-

wer tool or use the original packaging.

5. Protect the power tool against vibrations and shock,

especially during transport in vehicles.

Содержание 3903805958

Страница 3: ...3 І 160 1 6 3 2 5 1 4 14 12 11 13 1 2 3 4 5 13 9 ...

Страница 4: ...4 І 160 6 12 4 7 12 4 8 9 10 11 3 a ...

Страница 5: ...5 І 160 ...

Страница 156: ...156 І 160 ...

Страница 158: ...158 І 160 ...