Method of Installation (Piping)

-5-

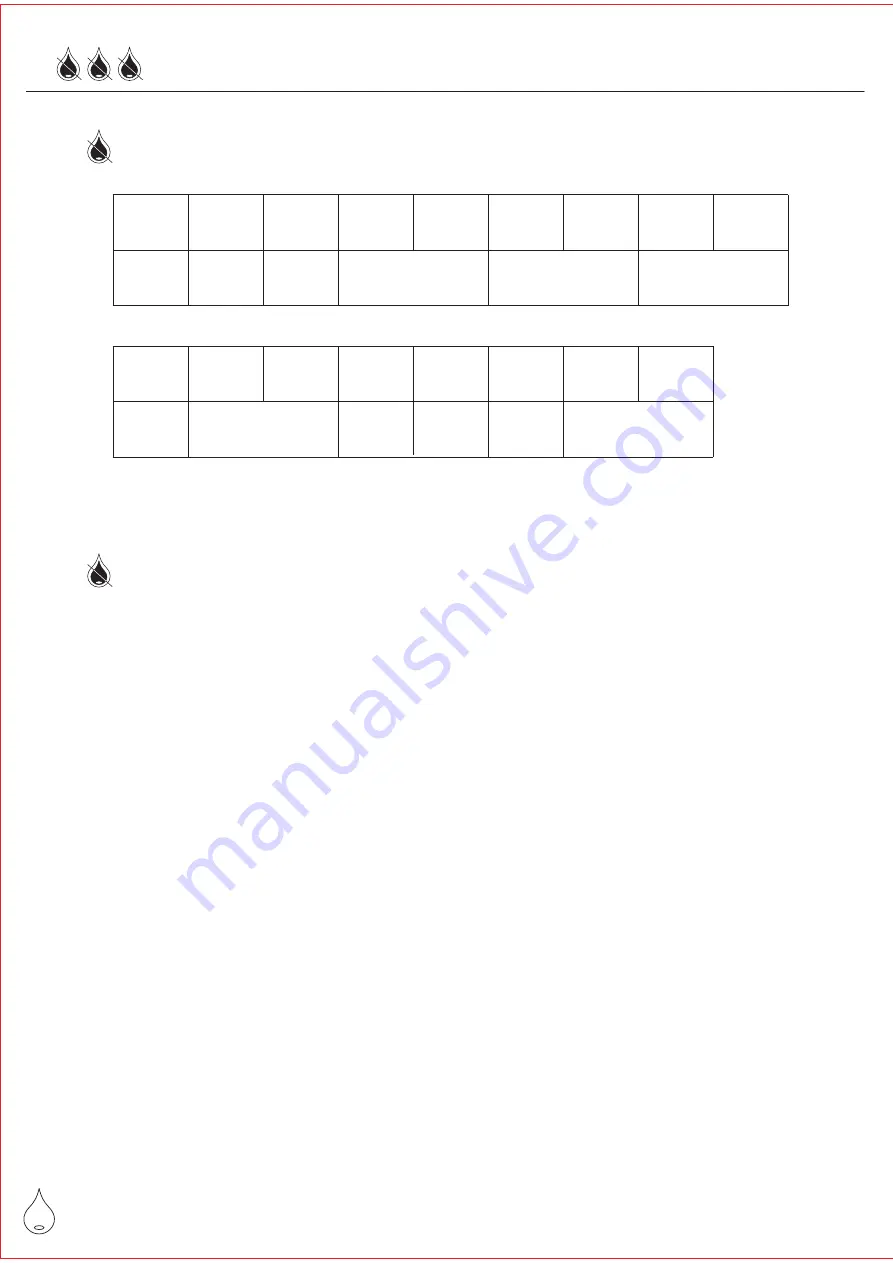

Diameters of Inlet And Outlet Pipes of Dryer

MODE AD-005

AD-010 AD-015 AD-020 AD-030 AD-040 AD-050 AD-060

PT

INCH

1/2"

3/4"

1"

1-1/2"

2"

MODE AD-075S AD-100S AD-150S AD-200S AD-250S AD-300S AD-400S

PT

INCH

2"

2-1/2"

3"

3"

4"FL

Piping Method

1. Please refer to the attached drawing 1 for installation procedures

when there is purifying equipment like gas tank and filter, etc.

2. Diameter of the air inlet and outlet of the dryer is the same. Pay

attention to wrong installation that may reduce the drying efficiency

of the dryer.

3. If the compressor shakes violently while running, install an extra

high-pressure vibration-proof hose unto the connection pipe

between the compressor and the dryer to protect the dryer.

4. Install valve gates and bypass pipes at the inlet and outlet of the dryer

for service and maintenance needs.

5. Diameters of the pipes should not be too small. Avoid long pipes with

many curves to reduce the loss from pressure drop.

6. Keep dust or unnecessary objects away from the air pipes while

installing.

Содержание AD-005

Страница 1: ...Operating Manual Freezing Compressed Air Dryer Http www dryer com tw E mail dryer dryer com tw...

Страница 17: ...Footnote 16...

Страница 18: ...Footnote 17...

Страница 19: ...Footnote 18...

Страница 20: ......