6

www.machineryhouse.com.au

www.machineryhouse.co.nz

1.

Daily - Air Supply Maintenance:

Every day, maintain the air supply according to the component manufacturers’ instructions.

Maintain the lubricator’s oil level. Use Pneumatic Tool Oil (Order Code A037)

Drain the moisture filter regularly.

Performing routine air supply maintenance will allow the tool to operate more safely and will also

reduce wear on the tool.

2.

Quarterly (every 3 months)

– Tool Disassembly, Cleaning, and Inspection:

Have the internal mechanism cleaned, inspected, and lubricated by a qualified technician.

3. For a full service contact your local Toolmaster service agent.

4. When not in use, disconnect from air supply, clean nibbler and store in a safe and dry place.

Maintenance

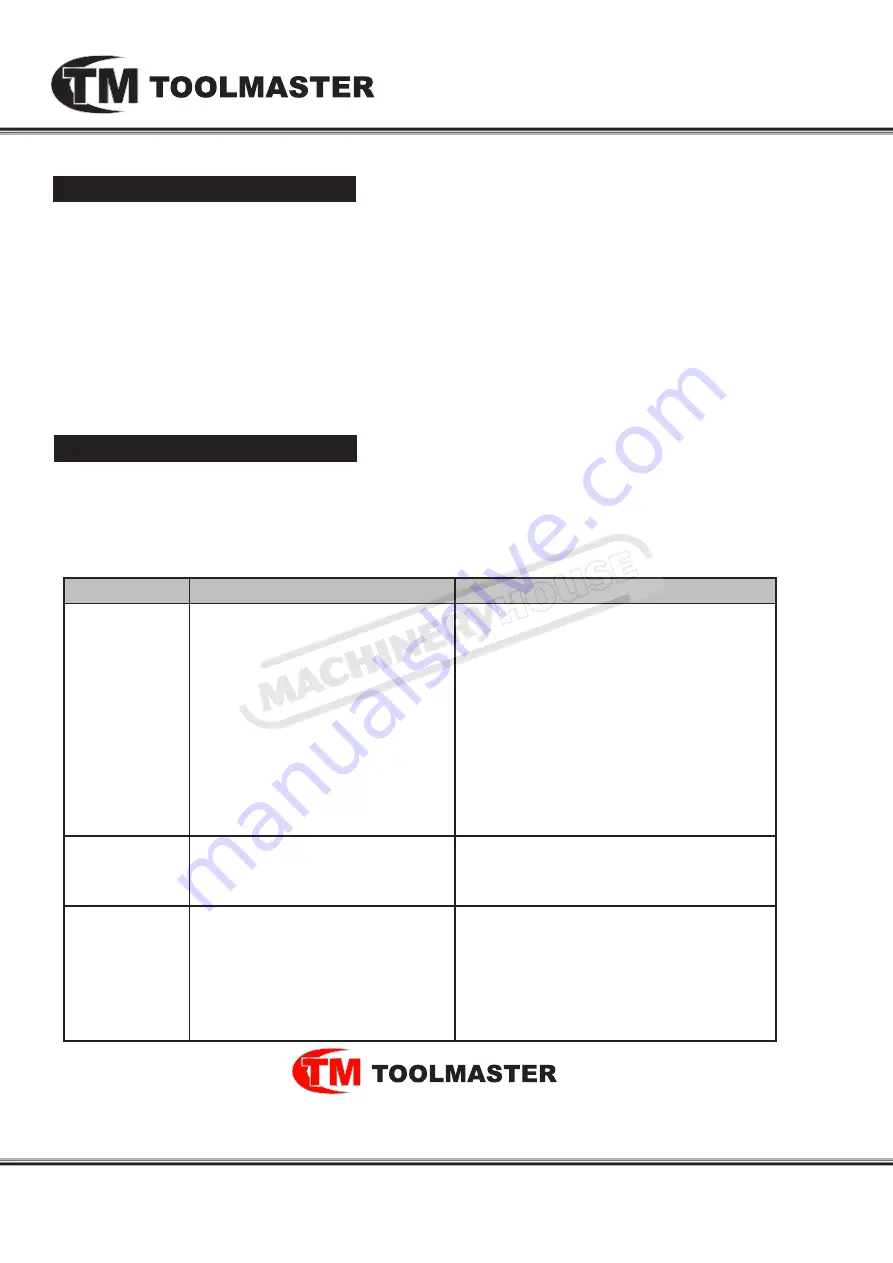

Symptoms

Possible Cause

Possible Solution

Decreased output.

1. Not enough air pressure and/or air flow.

2. Obstructed throttle.

3. Incorrect lubrication or not enough

lubrication.

4. Blocked air inlet screen (if equipped).

5. Air leaking from loose housing.

6. Mechanism contaminated.

7. Vane wear or damage.

1. Check for loose connections and make sure

that air supply is providing enough air flow

(CFM) at required pressure (PSI) to the tool’s air

inlet. Do not exceed maximum air pressure.

2. Clean around throttle to ensure free movement.

3. Lubricate using air tool oil and grease according

to directions.

4. Clean air inlet screen of buildup.

5. Make sure housing is properly assembled and

tight.

6. Have qualified technician clean and lubricate

mechanism. Install in-line filter in air supply as

stated in Setup: Air Supply.

7. Replace all vanes.

Housing heats

during use

1. Incorrect lubrication or not enough

lubrication.

2. Worn parts.

1. Lubricate using air tool oil and grease according

to directions.

2. Have qualified technician inspect internal

mechanism and replace parts as needed.

Severe air leakage

(Slight air leakage

is normal,

especially on older

tools.

1. Cross-threaded housing components.

2. Loose housing.

3. Damaged valve or housing.

4. Dirty, worn or damaged valve.

1. Check for incorrect alignment and uneven gaps.

If cross-threaded, disassemble and replace

damaged parts before use

2. Tighten housing assembly. If housing cannot

tighten properly, internal parts may be

misaligned

3. Replace damaged components.

4. Clean or replace valve assembly.

Review the troubleshooting and procedures in this section if a problem develops with your Air Tool.

If you are still unable to resolve the problem, then contact your local Toolmaster service centre. If

additional help with a procedure is required, then contact you distributor.

Note:

Make sure you have the model of the machine, serial number,and manufacture date

before calling.

Troubleshooting

INDUSTRIAL AIR TOOLS