5. Compaction Tips

5.1 Soil Drop Test:

Soil preparedness refers to the “wetness” of the dirt or soil. Soil needs

to be 50% dry and 50% wet, before starting compaction. A simple “hand test” can deter-

mine this. Pick up a handful of soil with your hand and squeeze the dirt. Observe whether

the soil is powdery or if it breaks apart when dropped. If the soil does break apart, it means

that it is too dry. If the soil keeps together in one piece when dropped, it is ready for com-

paction.

5.2 Soil Testing:

Testing: The function of this step is to measure the density of an aggregate

material to ensure the increase of density when driving out air. At a low moisture content

level, there are more soil particles assembling together. In order to determine if the soil is

compacted properly, there are several methods.

5.2.1 Soil Testing:

Test strips are useful to determine the method of compaction and

understand how many passes of your plate compactor are needed to achieve the optimum

compaction. Every layer of compacted soil meets a specific percentage on the proctor

curve. Through soil testing, it is possible to identify optimum moisture. Soil testing mea-

sures the soil density compared to the degree of compaction specifications, as well as the

effect of the moisture.

A common laboratory method called the Proctor Compaction Test can be used to deter-

mine the optimal moisture content for a given soil type. The goal of this method is to

understand the soil’s maximum dry density. A second method of soil testing is known as

the California Test 216 and is used to find the relative compaction of untreated and treated

soils.

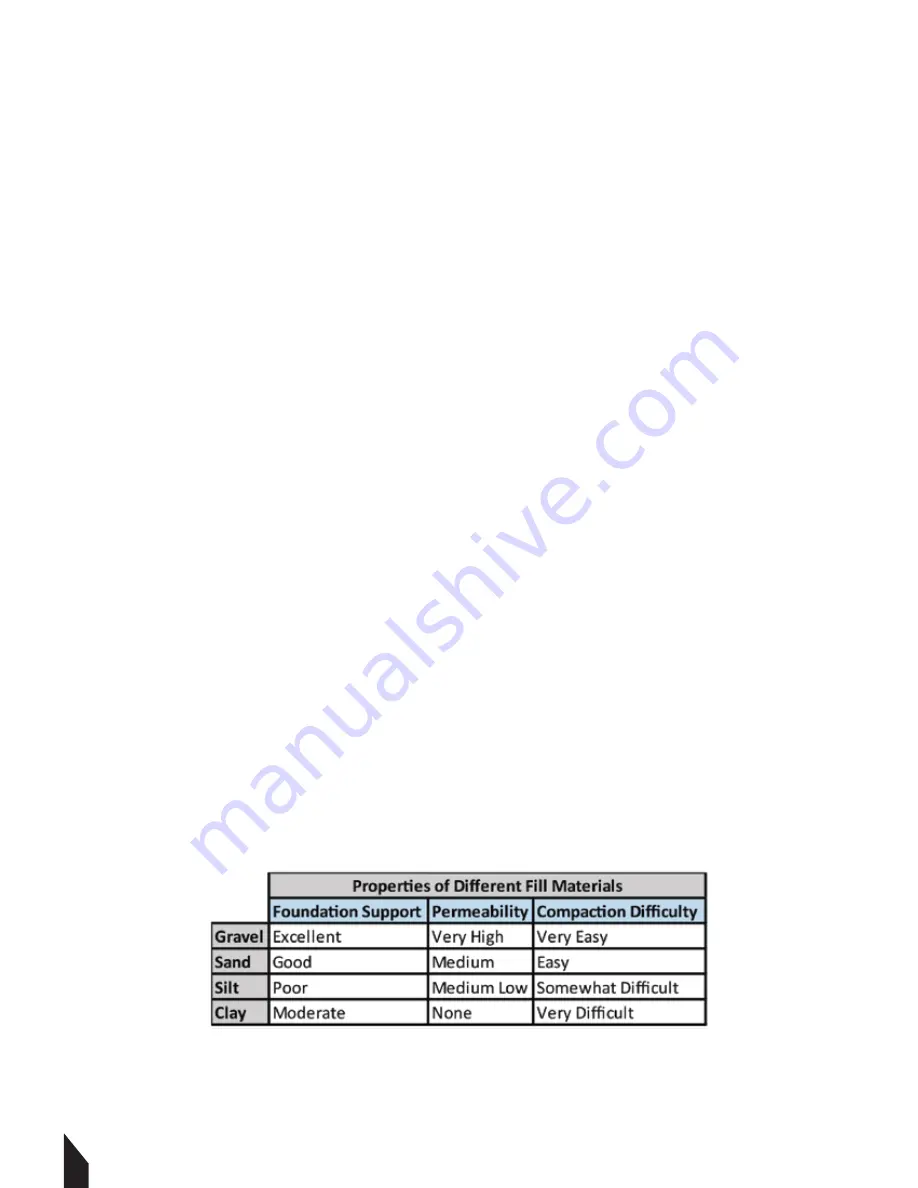

Four factors account for optimum compaction including lift thickness, pressure, and soil

moisture content. During the compaction process, the soil's moisture adds density and

lubricates soil particles, until there is a maximum dry unit weight without voids in the soil.

The table below explains the different outcomes and properties of fill materials.

26

Содержание TR68H

Страница 1: ...TR68H VIBRATORY RAMMER Operations Manual FIND THE HOW TO GUIDE ON YEAR WARRANTY Honda Engine on 3 ...

Страница 2: ...2 ...

Страница 9: ...9 3 Labeling 3 1 Label Locations ...

Страница 13: ...13 ...

Страница 23: ...7 Equipment Size 23 ...

Страница 29: ...TR68H VIBRATORY RAMMER Operations Manual 29 ...

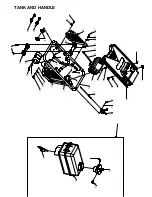

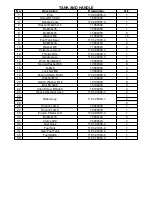

Страница 30: ... TANK AND HANDLE 17 ...

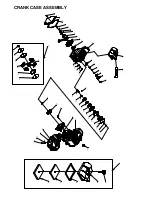

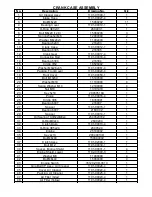

Страница 32: ... CRANK CASE ASSEMBLY ...

Страница 34: ... CYLINDER AND FOOT ASSEMBLY NOT INCLUDED ...