WWW.TMGINDUSTRIAL.COM

19 / 27

dŽůů&ƌĞĞ

:1-887-761-2819

O P E R A T I O N

6.

Ensure the blade is properly oriented, with the leading edge out. The blade is designed to fit into the

rotor one way only. See diagram for proper installation.

7.

Tighten down bolts as specified in the torque chart.

8.

Repeat steps for remaining blades.

Ledger Blades:

The TMG-WC62S is equipped with a ledger (stationary) blade that acts as a shear for the moving rotor

blades. The ledger blade is designed with 4 usable corners. When the corner facing the rotor blade rounds

over, remove the blade and reinstall with a different corner facing the rotor blade. It is recommended that the

clearance between the rotor and stationary blades be set and maintained at 1/32 to 1/16 " (.76 - 1.52 mm) to

obtain the best performance.

1.

Turn off the hydraulics, stop the engine, remove the

ignition key and place it in your pocket and wait for

all moving parts to stop.

2.

Remove the 2 bolts that hold the ledger blade to the

ledger mount, remove the blade.

3.

Rotate the blade and replace or replace with new or

re-sharpened blade.

4.

Hand tighten the bolts and set the clearance between the ledger and rotor blades at 1/32 - 1/16" .

5.

Tighten down bolts as specified in the torque chart

Содержание WC62S

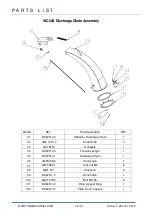

Страница 23: ...WWW TMGINDUSTRIAL COM 22 27 d 1 887 761 2819 P A R T S L I S T 0123...

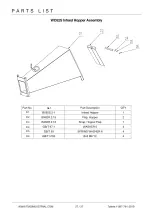

Страница 24: ...Infeed Hopper...

Страница 28: ...D D D D D D D1 Ref D2 D3 D4 D5 D6...