172-65260m-05 (S-COS/S-COSR Pressure Reducing Valve) 27 Oct 2008

11

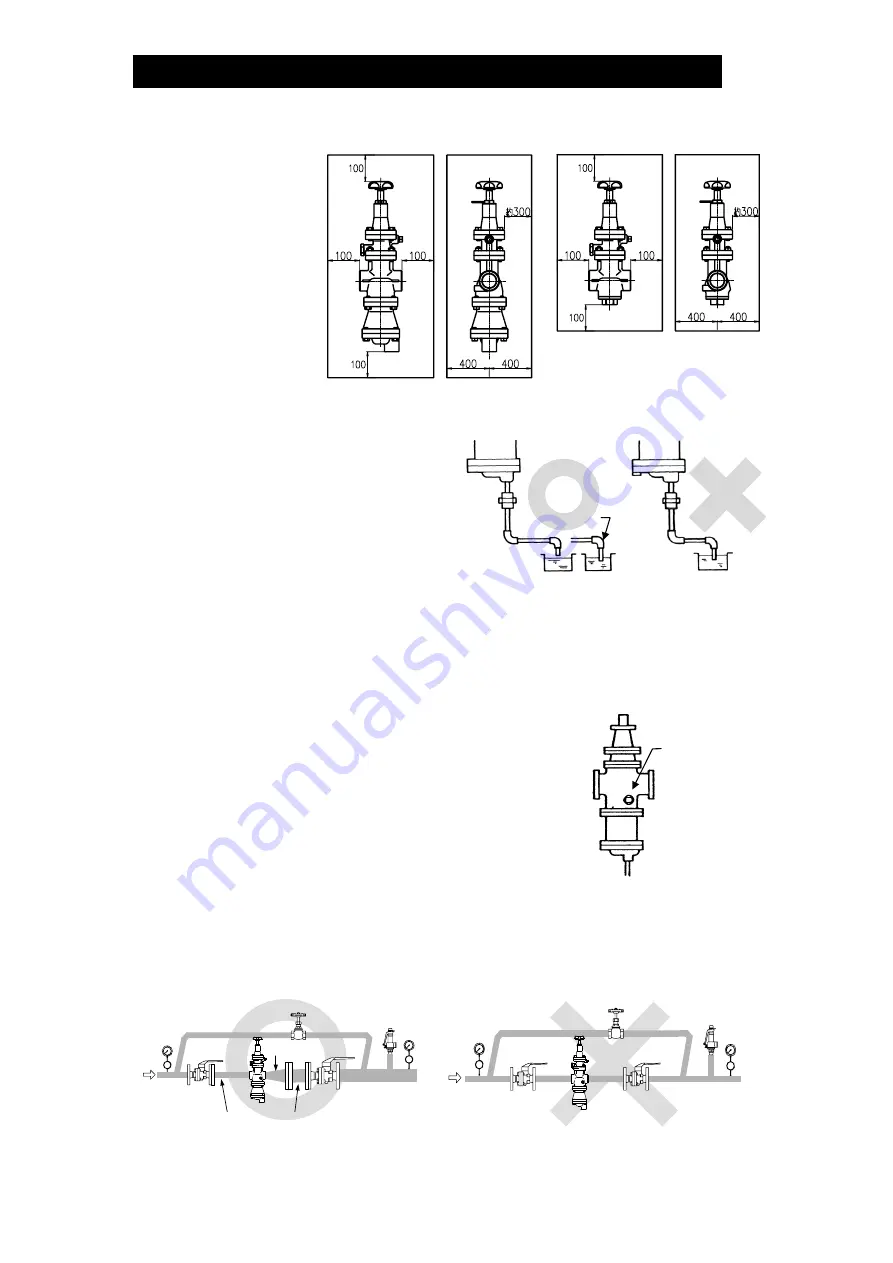

5. Maintenance Space

Leave sufficient

space for

maintenance,

inspection and

repair.

(Unit: mm)

6. Trap Outlet Pipe (S-COS Only)

For ease of maintenance, installation of

a union connection is recommended for

the trap outlet pipe.

Connect the outlet pipe to a condensate

return line, or extend it to a trench. In

the case of the latter, make sure the

end of the pipe is above the waterline.

(Dirt and water may be sucked up by

the vacuum formed during trap closure

and system shutdown.)

7. Blowdown Valve (requires product with optional plug)

In an environment of heavy dirt or scale, or when the steam equipment is used

only periodically, such as for room heating equipment,

be sure to use a blowdown valve.

1. Remove the plug from the main body.

2. Install the blowdown valve.

3. Open the blowdown valve and blow any residual dirt

and scale off of the screen.

4. Periodically activate the blowdown valve to keep the

system free of dirt and scale.

8. Piping Size

If it is expected that the secondary steam flow velocity will be more than 30 m/s,

install a diffuser in order to keep the flow velocity below 30 m/s. If the distance

between the reducing valve and the steam equipment is great, a possible drop in

pressure should be taken into consideration when selecting the piping size.

Straight-run Piping Lengths: Upstream = 10 d or more; Downstream = 15 d or more

(d = pipe diameter)

Diffuser

Small Hole

S-COS S-COSR

Remove the

¼” plug

(optional) and

install the

blowdown

valve.