172-65120MA-13 (CK-Series) 24 Aug 2020

7

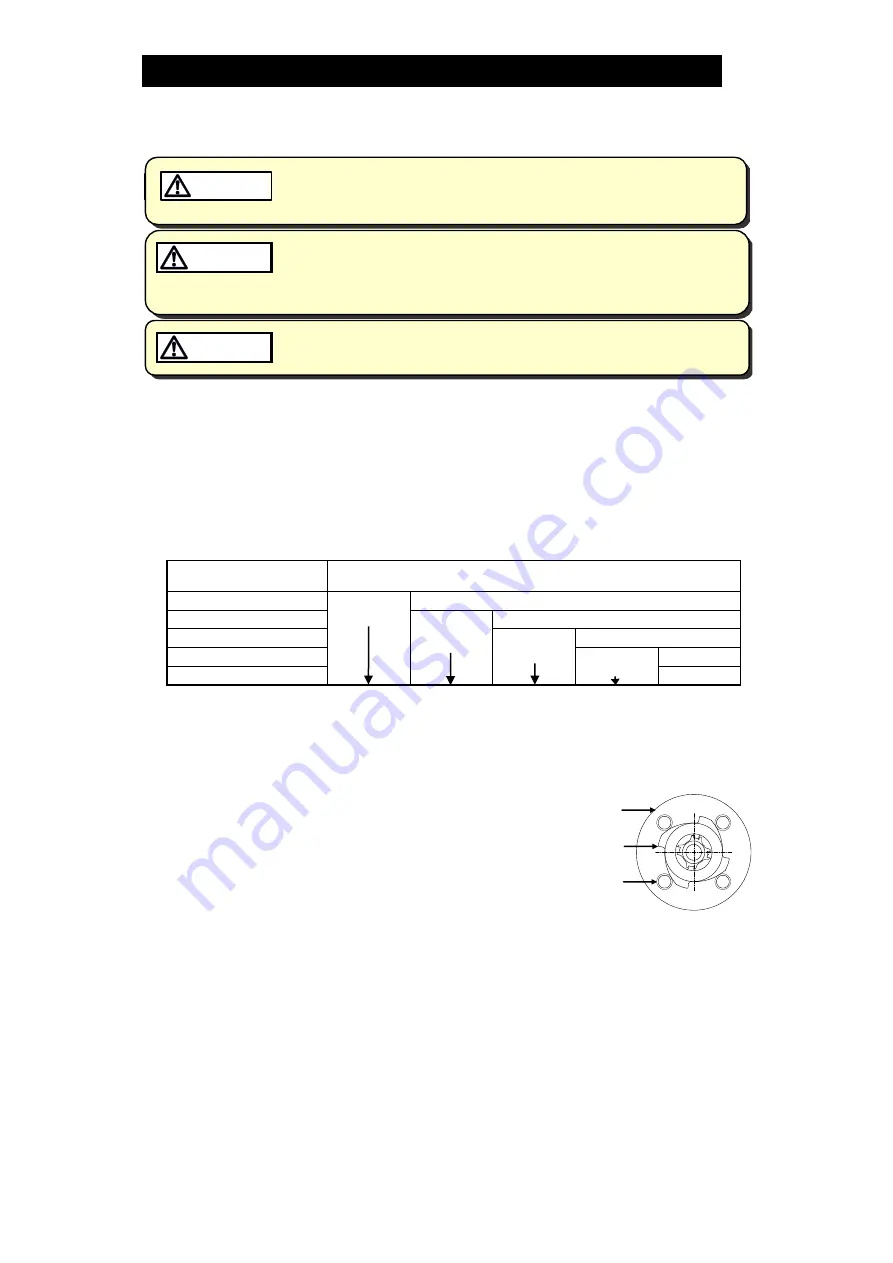

Flange

Fin

Bolt

Installation

WARNING

DO NOT use for toxic, flammable or otherwise hazardous fluids. Use only

for fluids listed in the specification table. This product is for intended use

only. Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Avoid installation directly after equipment that may cause sudden changes in

pressure or flow including water hammer and pulsation. (For example: high flow

ON-OFF valves or pumps that start and stop frequently) Strong shocks to

internal parts may result in damage to the spring or premature wear on the disc

valve and seating surfaces.

2. Temperature:

Maximum Operating

Temperature

Model

350 °C (662 °F)

CKF3M

CKF3MG

220 °C (428 °F)

CK3M

CK3MG

185 °C (365 °F)

CK3T

CK3T-M

150 °C (302 °F)

CKF3R

CKF3RG

90 °C (194 °F)

CK3R

NOTE: 1. Choose the model that meets operating temperature requirements

2. The CK3R optional FPM sealing model can be used to 150 °C (302 °F)

3. Before installation, be sure to remove all protective seals.

4. Before installing the product, blow out the inlet piping to remove any piping

scraps, dirt and oil. Close the inlet valve after

blowdown.

5. Before installing the product, open the valve to

make sure that the valve and the valve seat do not

stick to each other.

6. Install the product so the arrow on the body is

pointing in the direction of flow.

7. There are no restrictions on the direction of installation, however vertical piping

installation is recommended. To center the valve, install the CKF3M(R) and the

CKF3M(R)G with the bolts touching the fins (see the figure shown above).

8. When installing a screwed type, secure the inlet and outlet piping of the product

using supports, etc. to ensure that it does not place stress on the inlet union or

the body of the product.

9. Open the inlet valve, and perform the necessary checks to make sure that the

product functions properly.

If there is a problem, determine the cause using the “Troubleshooting” section in

this manual.