172-65143M-04 (BB1N·BBF1N) 7 Oct 2021

14

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

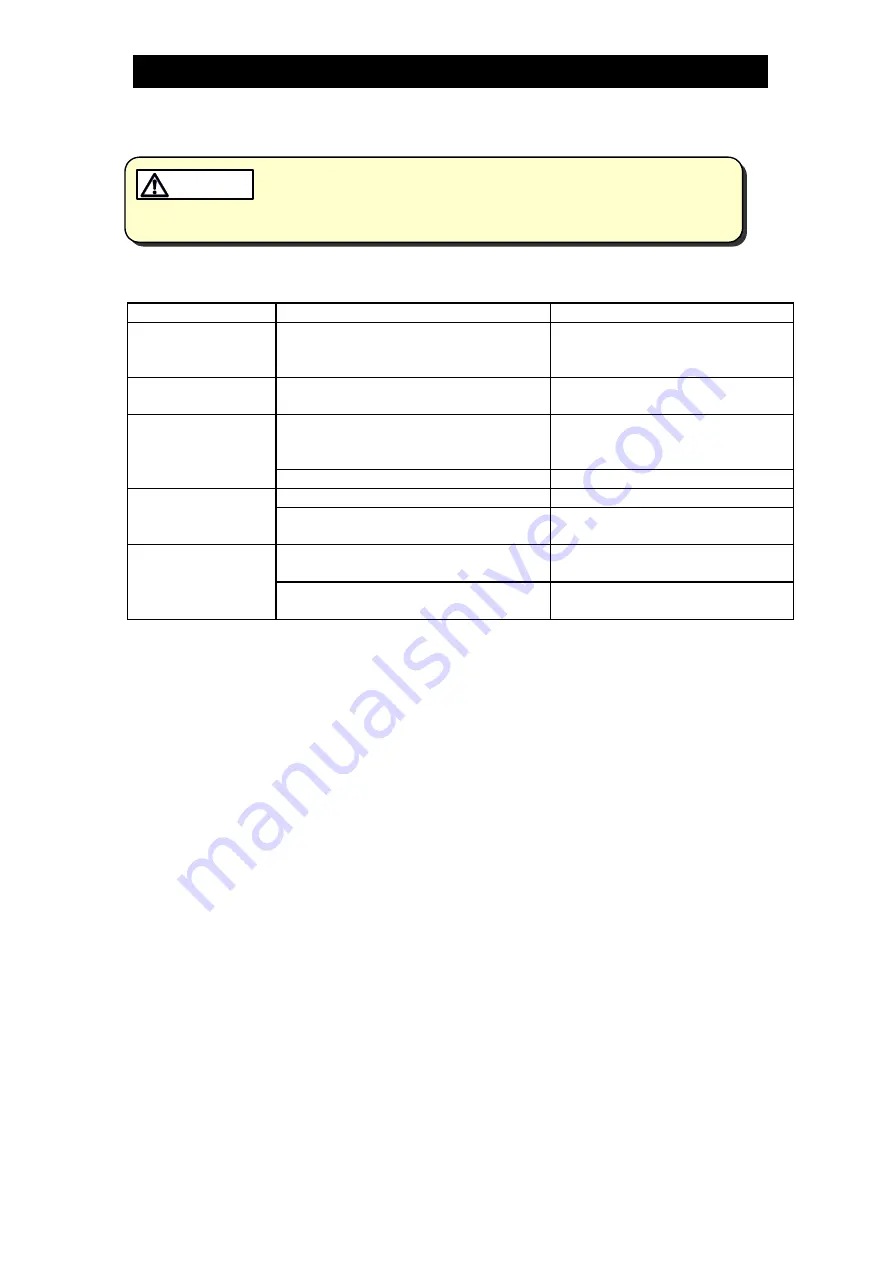

When the product fails to operate properly, use the following table to locate the cause and

remedy.

Problem

Cause

Remedy

Fluid leaks from the

outlet

The sealing area of the valve has build-

up or is scratched, or if the o-ring is

scratched or damaged

Clean or replace parts

Fluid leaks from the

gland section

There is build-up, scratches or wear on

the seal, stem packing or gasket

Apply additional tightening, clean or

replace parts

The valve does not

move or remains

half-open

The valve seat or ball have build-up, if

the valve seat is deformed, or if the ball

turns smoothly.

Clean or replace parts

The handle is worn or deformed

Replace with new handle

Fluid leaks from

Gasket deterioration or wear

Replace with a new gasket

inlet union or flange

connections

The inlet union or flange bolt is loose

Tighten it to the proper torque

The valve seat

becomes damaged

Check for the occurrence of water

hammer

Examine the piping for problems

that can cause water hammer

The valve is being used in the half-open

position

Use fully open or fully closed