Pressure Switch Replacement

See Figure 7

WARNING:

Before proceeding, follow the Pressure

Relief Procedure outlined on page 5. Additionally, follow

all other warnings to reduce the risk of an injection

injury, injury from moving parts or electric shock.

1. Remove socket head cap screws.

2. Remove electrical cover plate #60, located near pressure

switch and disconnect two red wires from clutch starter

#58. See pg. 20.

3. Remove screw #27 from pressure switch adjustment

knob and slide knob off.

4. Remove screw #27 located on side of gear box housing

#53 and using a 1/8" allen wrench remove set screw

#56, until pressure switch #231 is able to slide down

through. Feed electrical wires down at the same time.

5. Insert new switch assembly #231). See Figure 8, p. 22)

into housing while carefully working the wires into the

switch box. Using needle nose pliers, reconnect wires

to motor starter.

6. Making sure that the switch assembly is fully inserted,

tighten set screw #56 with a 1/8" allen wrench until the

switch assembly is secure. Reattach adjustment knob

#26. See pg. 20.

7. Inspect O-Rings #232 and #233 on switch assembly.

8. Install insulator plate #66 and plate #60. See pg. 20.

9. The pressure switch is factory calibrated so no

adjustment is required.

Service/Replacement of the

Pressure Relief Prime Valve

WARNING:

Before proceeding, follow the Pressure Relief

Procedure outlined on Page 5. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock.

1. Remove the Dowel Pin (#226) from Bypass Valve Handle

(#227).

2. Remove Handle (#227) and Bypass Cam (#225).

3. Using a wrench, loosen Bypass Housing (#218) and

unscrew.

4. Unscrew Bypass Retainer (#224) and remove Bypass Valve

Stem (#220).

5. Inspect ball on end of Stem (#220) and O-Ring (#219). Clean

or replace if worn.

6. Screw completed assembly into Filter Block (#207). Tighten

securely with wrench.

7. Install Bypass Cam (#225) over Bypass Retainer (#224),

lubricate with grease. Line up Dowel Pin (#226) on Cam

(#227) with hole on Filter Block (#207).

8. Using Dowel Pin (#226) line up Stem (#220) with hole on

Handle (#227). Secure Handle with Dowel Pin (#226).

9. IMPORTANT: If Handle (#227) rotates 360° check Pin on

Cam (#225).

Service / Replacement

of Filter

WARNING:

Before proceeding, follow the Pressure Relief

Procedure outlined on Page 5. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock.

PUMP FILTER

1. Unscrew Filter Housing (#202).

2. Remove Filter Cartridge (#204). Clean or replace.

3. Inspect O-Ring (#206). Clean or replace.

4. Reattach Filter Housing (#202).

Gun Filter

WARNING:

Follow all safety precautions as described in

high pressure warning section before proceeding. If your

spray gun leaks or spits at the tip when you release the

trigger, the needle or seat is dirty, worn or damaged and

must be cleaned or replaced.

Replacement or Removal of Filter:

1. First pull down on trigger safety guard and swing away from

handle.

2. Unscrew handle from spray head.

3. Unscrew left hand threaded* filter from spray head. (*NOTE:

Left handed thread requires turning the filter clockwise to

remove.)

4. Screw new or cleaned filter into the head. (To reinstall left

hand thread turn counterclockwise.)

5. Reattach handle to head and secure safety trigger guard.

(NOTE: If filter breaks off in the head use a small wood

screw to remove.)

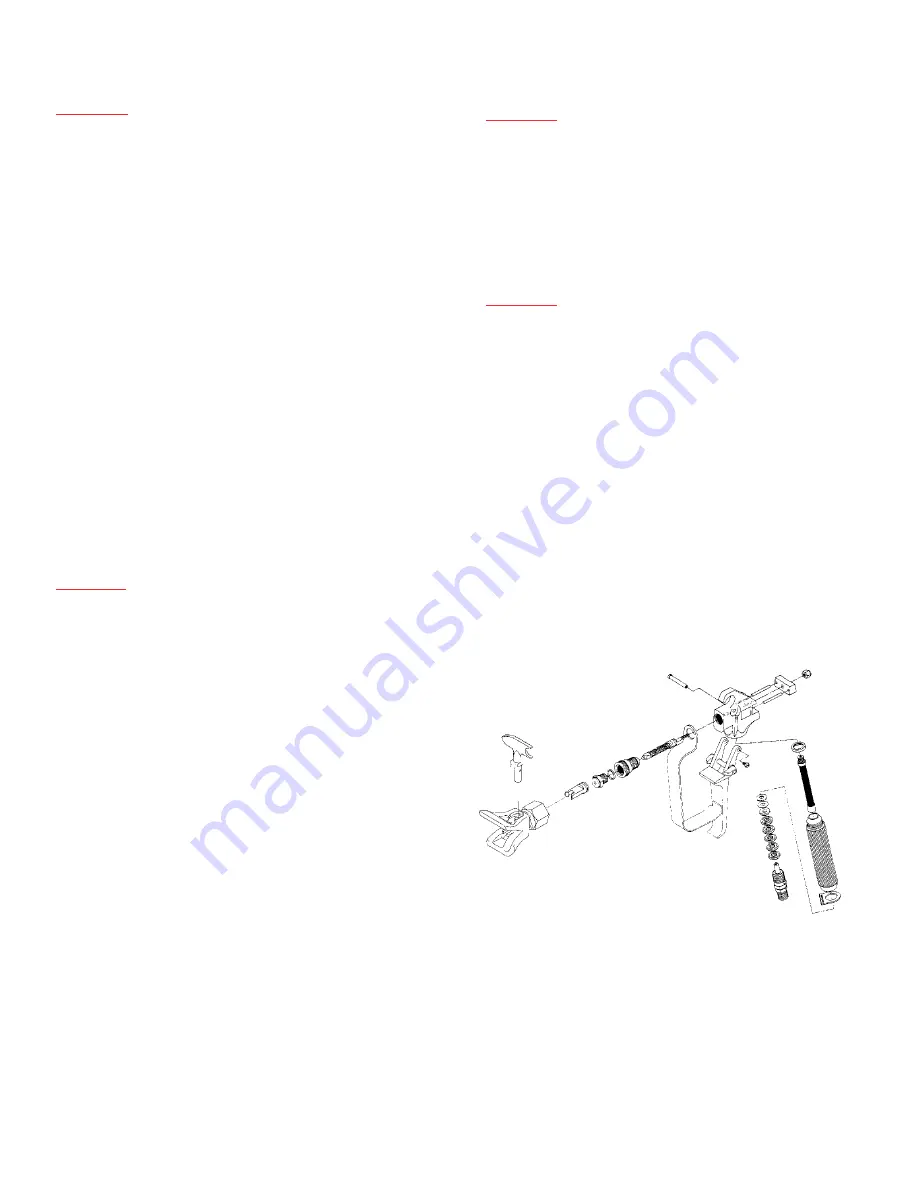

Figure 9 For more detail, part number information and assembly

drawings at larger scale, please see the LX-80 Professional

Airless Gun Owner’s Manual (#313-012).

23