- 23 -

1.

Make sure copper tip must not connect to work piece directly when user is cutting.

Torch should be inclined and it is 1 mm from inter-hole of copper tip to work piece

in order to protect copper tip.

2.

As arc-supporting cutting machine ,if arc-supporting frequency is down or there is

no arc-supporting ,user may be get rid of oxidized film of inter electrode by abrasive

paper .Then machine will be operated normally .

MAINTENANCE AND CHECK TROUBLE

Maintenance

1.

Remove dust by compressed air regularly .If cutting machine is placed in

environment where condition is polluted with smoke and dust, cutting machine must

be removed dust every day .

2.

Pressure is adequate to cutting in order to protect little components.

3.

Check the electrify connectors and make sure the connectors are connected firmly

(specially connect and insert components),tighten the connectors.

4.

Avoid water into machine and machine become damp, or the machine must be dried

in time and measured insulation by meter. After there is no problem, the machine

can be operated .

5.

If the machine will not be used long time, it should be put in its own packing box

and store in dry environment.

Check Fault

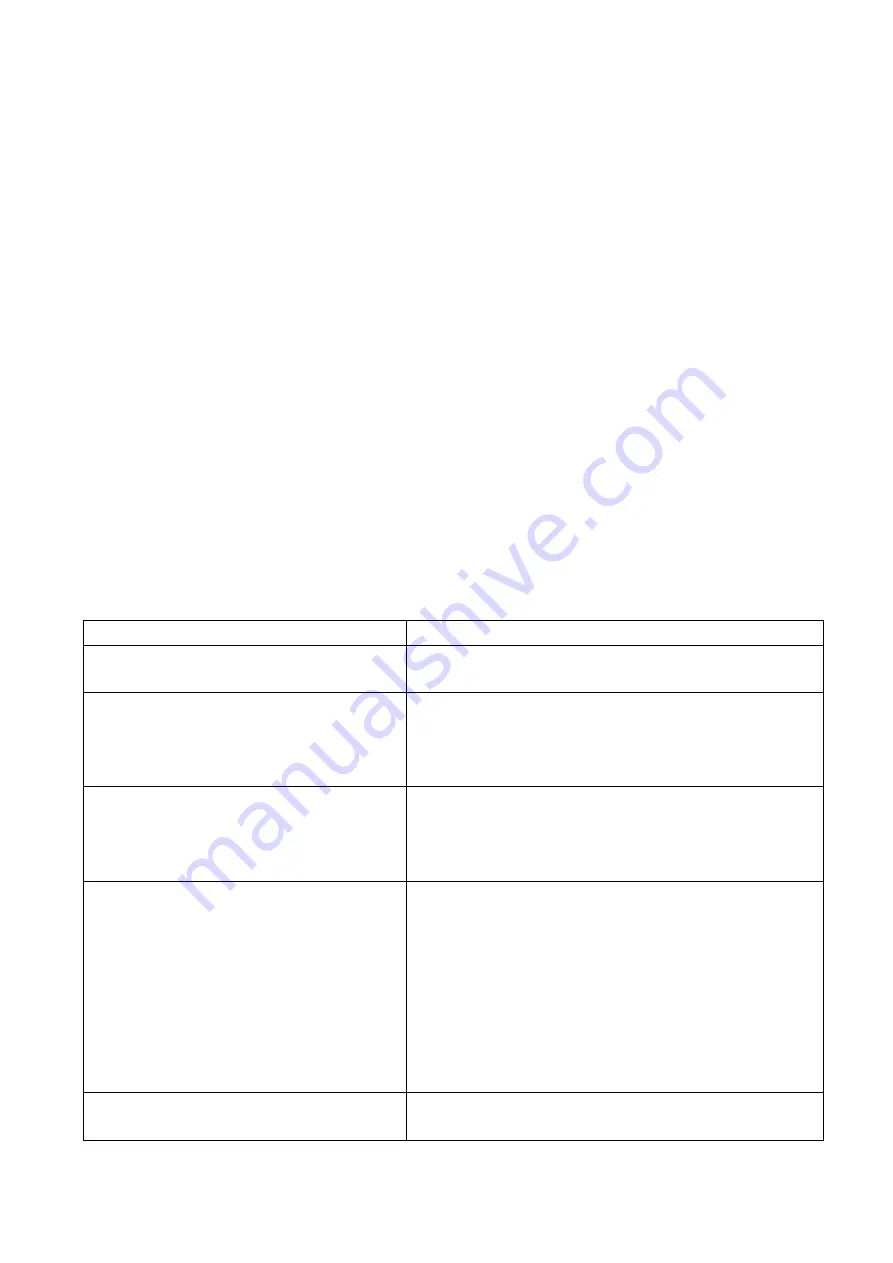

CUT-30/40/50

Faults

Resolvable Methods

1.Switch indicator is on ,fan is not

working and control knob is out of work.

1.Over voltage protection is working.Close machine

then open it again after several minutes.

2.Switch indicator is lit and fan is

working .However ,press control knob of

torch ,there is no HF arc-striking sound

and electromagnetic valve is not working.

1.

Check if torch is open circuit.

2.

Check if control knob of torch is damaged.

3.

Part of assistant power of top board is damaged and

there is no DC 24v output.

3.Switch indicator is lit and fan is

working .However ,press control knob of

torch ,there is no HF arc-striking sound

and inter red diode is lit .

1.

Check if MOS K1170 of top board is damaged

(driver mould is damaged ).

2.

Rising transformer of bottom board is damaged.

3.

Control mould is damaged.

4.

Switch indicator is lit and fan and

electromagnetic valve are working.

However, there is no sound of HF

arc-striking and inter red diode is not

lit.

There is some trouble in part of arc-striking ,such as:

1.

It is too far between discharge tip or there is

adhesion in discharge tip .

2.

Primary coil of arc-striking transformer is damaged

or poor contact.

3.

Check if four times voltage rectifier diode is

stricken.

4.

Check if HF electric capacity 102/10KV is leaking.

Relay is damaged.

5.Other of machine is normal ,but arc is

not be stricken when it is be operating.

1.

Input voltage is too low.

2.

Pressure of air compressor is too high or too low.