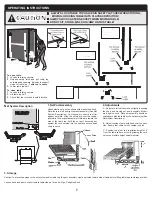

CAUTION

AT LEAST TWO ADULTS ARE NEEDED TO COMPLETE THE

FOLLOWING STEPS! DO NOT LEAVE TABLE UNATTENDED UNTIL

ASSEMBLY IS COMPLETE!

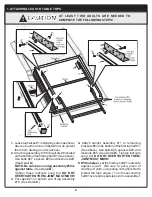

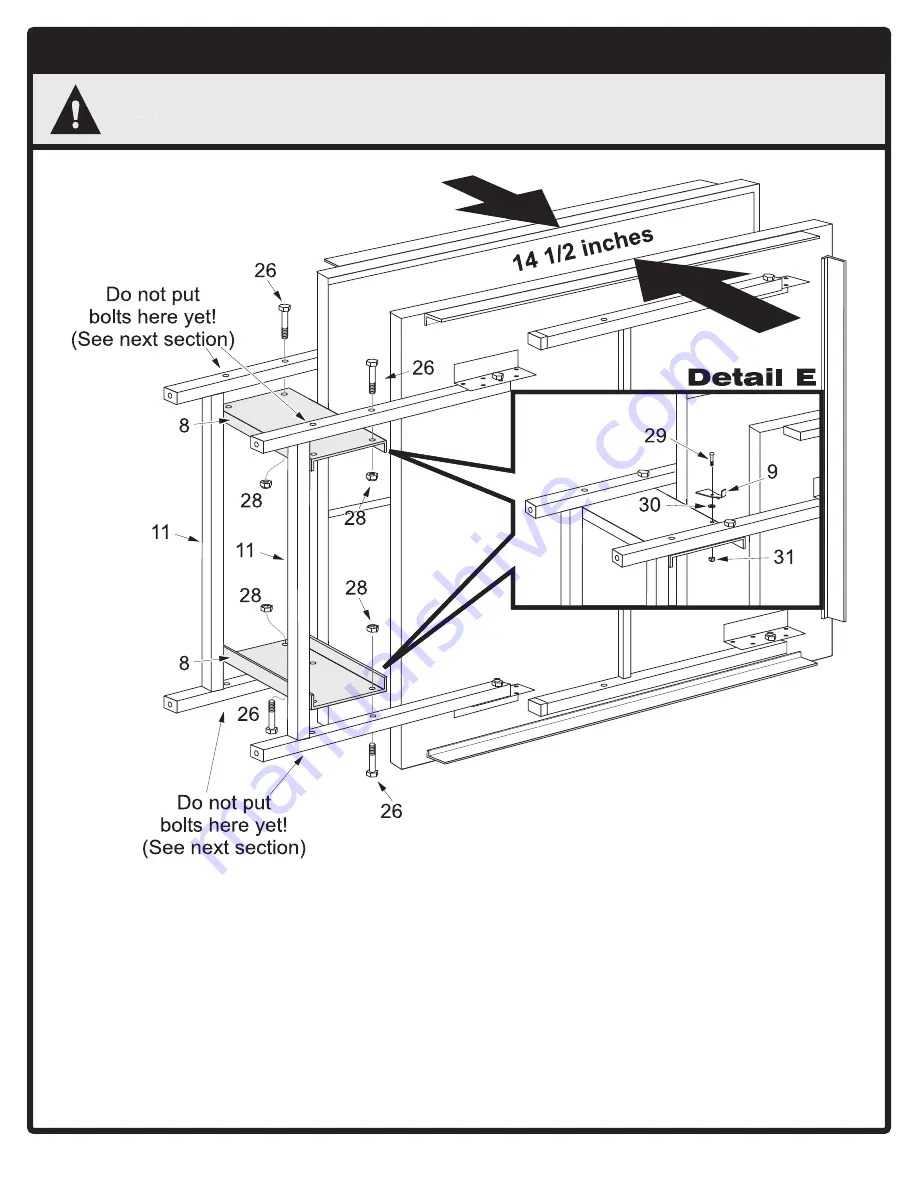

2. ATTACHING NAME PANELS TO LEGS

6. With a helper, hold top halves about 14 ½

inches apart.

Attach only

one half

of name panels

#8 to upright assemblies #11 as shown above.

Use

ONLY TWO

bolts #26 and locknuts #28

on

each name panel.

(

Two other bolts #27 and nuts #28 will be used in

the next section to attach the other half of the

name panels and linkages #24 at the same time.

See next page.

)

Do not tighten these locknuts

completely tight yet

.

HELPFUL HINT:

Start at the bottom and insert

two bolts #26

UPWARD

through upright

assemblies #11 and name panel #8. Then attach

the upper name panel #8. Insert bolts #26

DOWNWARD

.

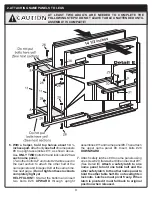

7.

Attach safety latches #9 to name panels using

one screw #29, flat washer #30 and locknut #31.

(See Detail

E

).

Attach a safety latch to one

name panel to hold one table half and the

other safety latch to the other name panel to

hold the other table half. Do not overtighten

locknuts. Latches must pivot freely. When

latch is pivoted it must fall back to original

position when released.

3