44

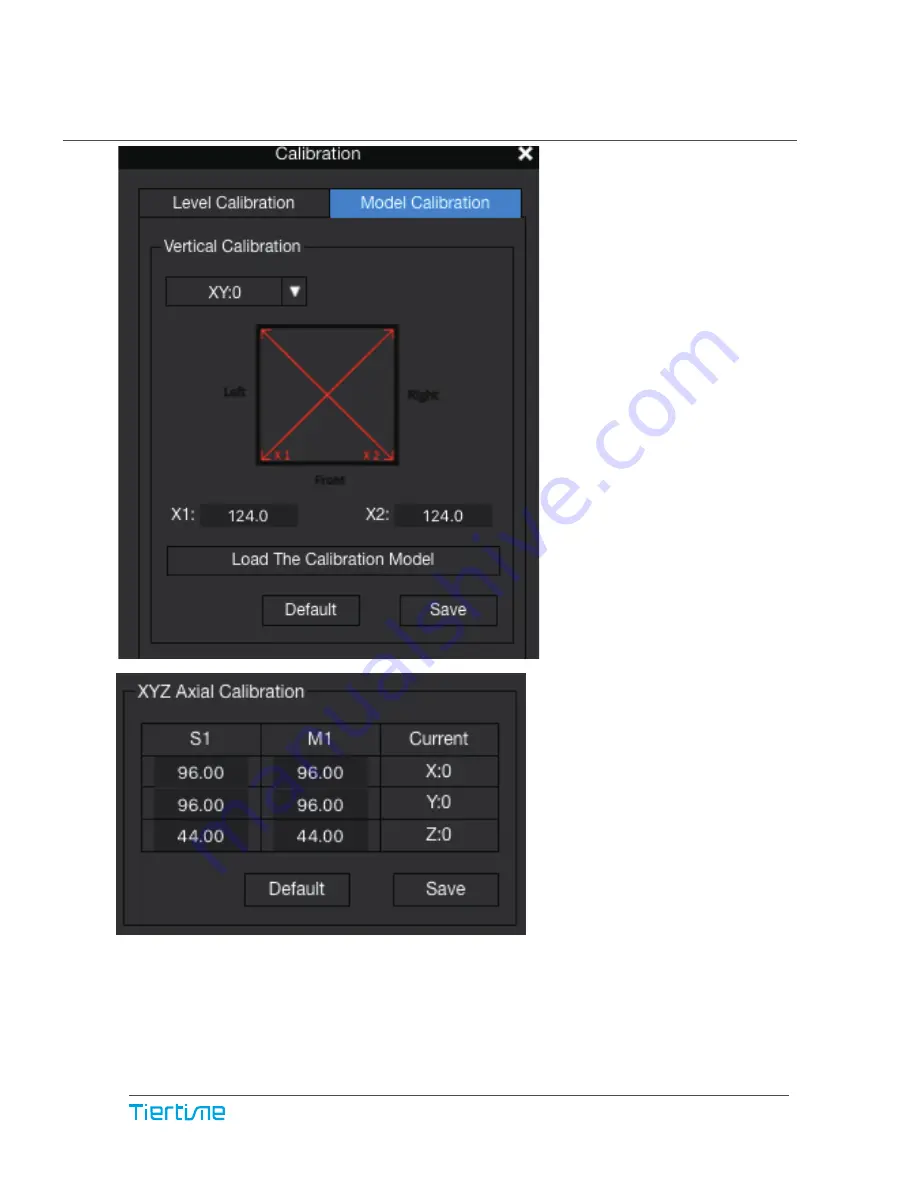

Model Calibration

XYZ Axial Calibration is used to improve dimensional accuracy for a specific model.

When a printed object is found to be deviating from its theoretical dimensions, we can

use this method to correct it and achieve better precision.

For detailed instruction, go to www.tiertime.com, Tips and Tricks section.

Vertical Calibration, its main

purpose is to ensure all

three axes are perpendicu-

lar to each other in order to

guarantee consistent,

high-quality prints.

Содержание UP Mini 2 ES

Страница 1: ...V 0 1 User Manual Download the full user manual at www tiertime com Support Section ...

Страница 7: ...Filament Spool Holder Spool Hold Lid Filament Spool Tool Drawer Filament Filament Guiding Tube 05 ...

Страница 8: ...Installation of Print Board Slide print board into the platform 06 ...

Страница 20: ...Loading a 3D Model Load Model Button 18 ...