DTH Electric Boilers USE & CARE MANUAL

(Revision June 2014)

, Page

8.

3.4.7 Circulator zoning recommendations

The preferred location of the circulator pump for

each zone is on the boiler supply side, with the

expansion tank between the boiler and the

pump.

A flow check valve must be installed in each

zone, preferably on the outlet side of each

circulator pump, to prevent water flow to other

zones where no heat is required.

3.4.8 Zone valve zoning

recommendations

The preferred location of the circulator pump is

on the boiler supply side, with the expansion

tank between the boiler and the circulator. Use

zone valves with low pressure drop.

3.4.9 Pump & pipe sizing

3.4.9.1 Boiler water temperature drop (BWTD)

through the heating loop

A simplified design method based on a 20°F

temperature drop (BWTD) between boiler outlet

and inlet is commonly used. Although such a

method is widely used and generates

satisfactory system performance when applied

properly, it does not determine the system

operating point. The pipe size is often

uneconomically large, and the actual system

flow rate is likely to be much higher than

intended. Such design methods seldom

consider temperature drops higher than 20°F,

which results in overdesign.

Another method by which the boiler water

temperature drop (BWTD) could be calculated

is to assume a constant supply boiler water

temperature minus the return boiler water

temperature. For example a boiler might have

a return temperature of 140 °F. Assuming a

constant supply boiler temperature of 180 °F,

the BWTD would be 40 °F ( = 180 °F – 140 °F).

Second example: If the boiler water has a return

temperature of 120 °F and the boiler supply is at

140 °F, then the temperature drop is 20 °F

(=140 °F – 120 °F).

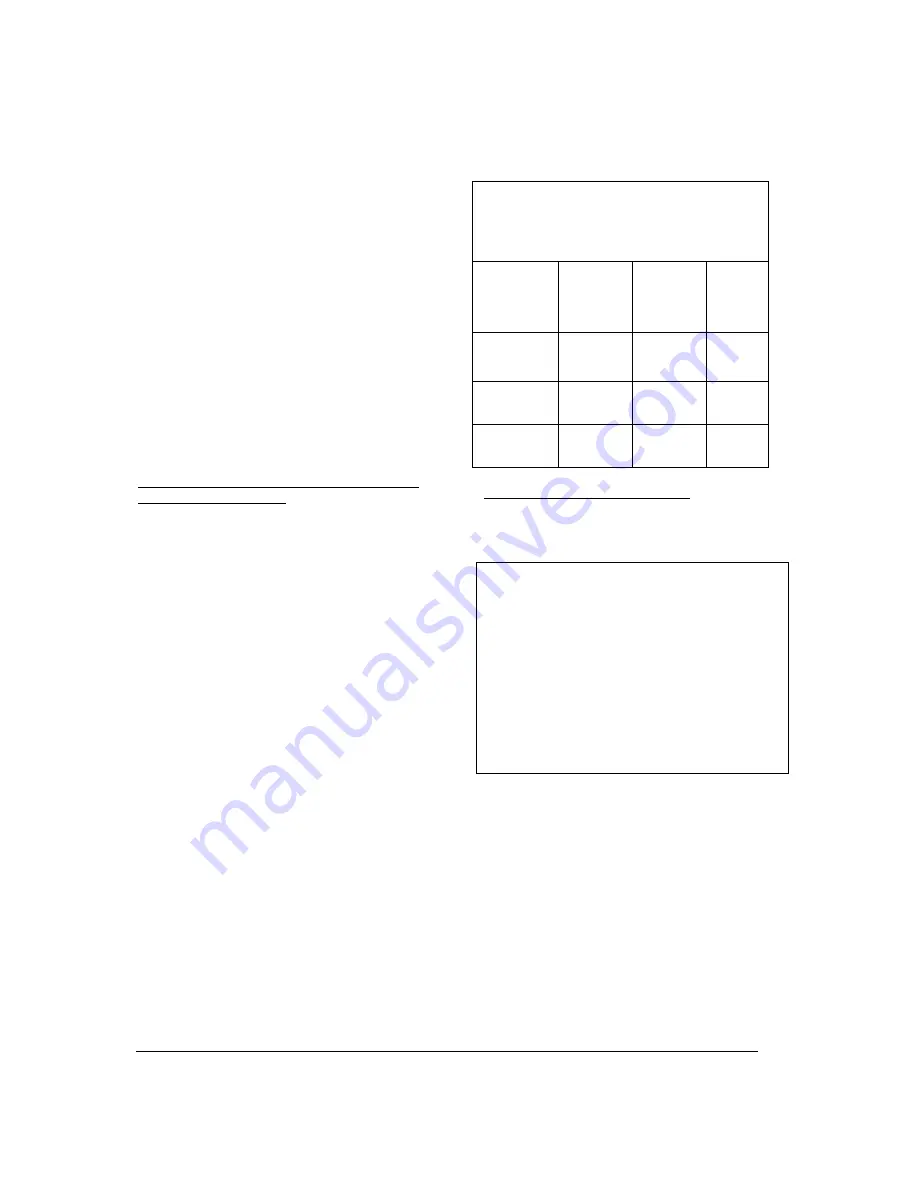

The following table suggests temperature drops

(BWTD) to be used in calculating the pump flow

rate.

Table 5: Temperature rise through the boiler

PROPOSED BOILER WATER

TEMPERATURE RISE THROUGH THE

BOILER (BWTD)

System

type

Boiler

water

Supply

tempera-

ture

Boiler

water

Return

tempera-

ture

BWTD

Baseboards

190°F to

140°F

170°F to

120°F

20°F to

40°F

Cast Iron

Radiators

160°F to

130°F

140°F to

110°F

20°F to

40°F

Radiant

In-Floor

130°F to

90°F

110°F to

70°F

10°F to

20°F

3.4.9.2 Pump flow rate calculation

The boiler output rating must correspond to the

calculated heating load. Use the equation below

to calculate the pump flow rate.

Pump flow rate = Boiler output

÷÷÷÷

BWTD

÷÷÷÷

500

•

Pump flow rate is expressed in US gallons

per minute or GPM.

•

The Boiler output ( in net BTU per hour) is

the maximum amount of heat to be

transferred through the heating loop to meet

the heating load.

•

BWTD is the boiler water temperature drop

For example, an electric boiler rated at 144KW

has a power output of 491,328 BTU per hour.

The system is designed for a temperature drop

(BWTD) of 20°F.

Required pump flow rate = 491,328

÷

20

÷

500 =

49.1 GPM

The following table lists the required pump flow

rate as a function of boiler power and BWTD.

Содержание DTH 102

Страница 4: ...DTH Electric Boilers USE CARE MANUAL Revision June 2014 Page 4 Figure 1 Component identification ...

Страница 12: ...DTH Electric Boilers USE CARE MANUAL Revision June 2014 Page 12 Figure 2 Wiring diagram DTH 96KW 240V ...

Страница 13: ...DTH Electric Boilers USE CARE MANUAL Revision June 2014 Page 13 Figure 3 Wiring diagram DTH 144KW 480V ...

Страница 14: ...DTH Electric Boilers USE CARE MANUAL Revision June 2014 Page 14 Figure 4 Wiring diagram DTH 144KW 600V ...