CARE AND CLEANING

Any piece of equipment works better and lasts longer when properly maintained. Cooking equipment is no

exception. Your THERMA-TEK appliance must be kept clean during the workday and thoroughly cleaned at

the end of the day.

OPEN TOP

Remove grates and burners and wash thoroughly with hot soapy water. Be sure to clean burner ports

by using a piece of wire

Make sure air shutter openings are clear of any debris.

Make sure pilot flashtubes are clear.

BROILER

Remove large pieces of food residue and carefully scrape spillovers from the drip tray below the

cooking surface.

Cast iron grates should be scraped with a wire brush frequently, and periodically soaked in hot water

to remove grease from the pores of the cast iron. Never expose the grates to extreme heat for the

purpose of burning off excess grease. This practice will shorten the life of the grates.

The lava rock in the Char-rock broiler are highly porous and relatively self-cleaning. High heat will

effectively clean and burn off grease. The lava rock should be turned over about every week

depending on the amount of cooking being done and the type of food being prepared.

GRIDDLE

Scrape with a nylon griddle scraper to remove cooked on spills. Use a fine-grained stone only when

absolutely necessary.

Wipe away any griddle stone dust and food particles with a cloth.

Wash with hot soapy water, then rinse with vinegar and water solution.

Then rinse again with clean water.

Re-oil with shortening or liquid frying compound.

Remove grease can, empty, and clean it thoroughly with hot soapy water.

Never flood the griddle with cold water. This promotes griddle warping and can cause the griddle plate

to crack if continued over a long period of time.

STAINLESS STEEL

All stainless steel body parts should be wiped regularly with hot soapy water during the day and with a

liquid cleaner designed for this material at the end of each day. Do not use steel wool, abrasive cloths,

cleansers, or powders to clean stainless steel surfaces. If it is necessary to scrape stainless steel to

remove encrusted materials, soak in hot water to loosen the material, then use a nylon or wood scraper

to loosen debris. Never use a spatula, knife or any other metal tool to scrape stainless steel. These tools

will scratch the stainless steel.

7

Содержание TC36-6

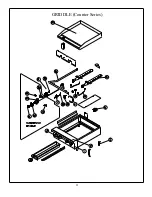

Страница 10: ...9 HOT PLATE Counter Series ...

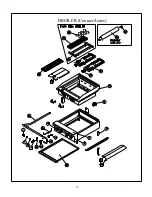

Страница 12: ...GRIDDLE Counter Series 11 ...

Страница 14: ...BROILER Counter Series 13 ...