quest

quest

1-866-933-7486

Quest PowerDry 4000 Pro

Installation, Operation and Maintenance Instructions

8

www.QuestProtect.com

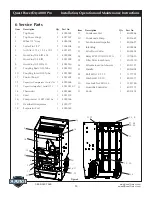

4.2 Technical Description

The Quest PowerDry 4000

Pro

uses a refrigeration system similar to an air conditioner’s to remove heat and moisture

from incoming air, and to add heat to the air that is discharged (see Fig. 2).

Hot, high pressure refrigerant gas is routed from the compressor to the condenser coil (see Figure 2). The refrigerant

is cooled and condensed by giving up its heat to the air that is about to be discharged from the unit. The refrigerant

liquid then passes through a filter/drier and capillary tubing which cause the refrigerant pressure and temperature to

drop. It next enters the evaporator coil where it absorbs heat from the incoming air and evaporates.

The evaporator operates in a flooded condition, which means that all the evaporator tubes contain liquid refrigerant

during normal operation. A flooded evaporator should maintain constant pressure and temperature across the entire

coil, from inlet to outlet.

The mixture of gas and liquid refrigerant enter the accumulator after leaving the evaporator coil. The accumulator

prevents any liquid refrigerant from reaching the compressor. The compressor evacuates the cool refrigerant gas from

the accumulator and compresses it to a high pressure and temperature to repeat the process.

4.3 Troubleshooting

No dehumidification, neither hour meter display nor compressor run and POWER button does not turn ON.

1. Unit unplugged or no power to outlet

2. Defective control board

3. Loose connection in internal wiring

No dehumidification, neither hour meter display nor compressor run with POWER button ON.

1. Defective control board

2. Loose connection in internal wiring

Some dehumidification, air mover runs continuously but compressor only runs sporadically.

1. Unit is in defrost cycle, DEFROST light on

2. Check to make sure humidistat is set high enough

3. Defrost thermistor defective or loose

4. Loose connection in compressor circuit

5. Defective compressor overload

6. Defective compressor

7. Defective relay

8. Low refrigerant charge

No dehumidification, air mover runs but compressor

does not.

1. Bad connection in compressor circuit

Figure 2: Refrigeration system of Quest