Useful information

General:

The distribution of wet or moist material will change the dispersion pattern and increase the risk of

clogging the impeller. Clean your spreader thoroughly after each use. Be especially thorough around

the impeller and other rotating parts.

Assembly:

To ensure a smooth dispersion it is of great important that the gear is installed properly. Ensure that

the gearbox is turned correctly. Make certain that the “front” label on the gearbox is pointing forward.

If the gearbox has incorrectly been installed in reverse, the impeller will rotate counterclockwise.

Maintenance:

After each use; always clean the impeller parts of the spreader. This will reduce the risk of clogging the

impeller wheel and mouthing. Dirt in the impeller wheel, will give an uneven dispersion.

Operation:

The machine is designed to be operated at normal walking speed. Slower or faster speeds, will change

the dispersion patterns.

Warning:

The gearbox is permanently lubricated at the factory, never open the gearbox.

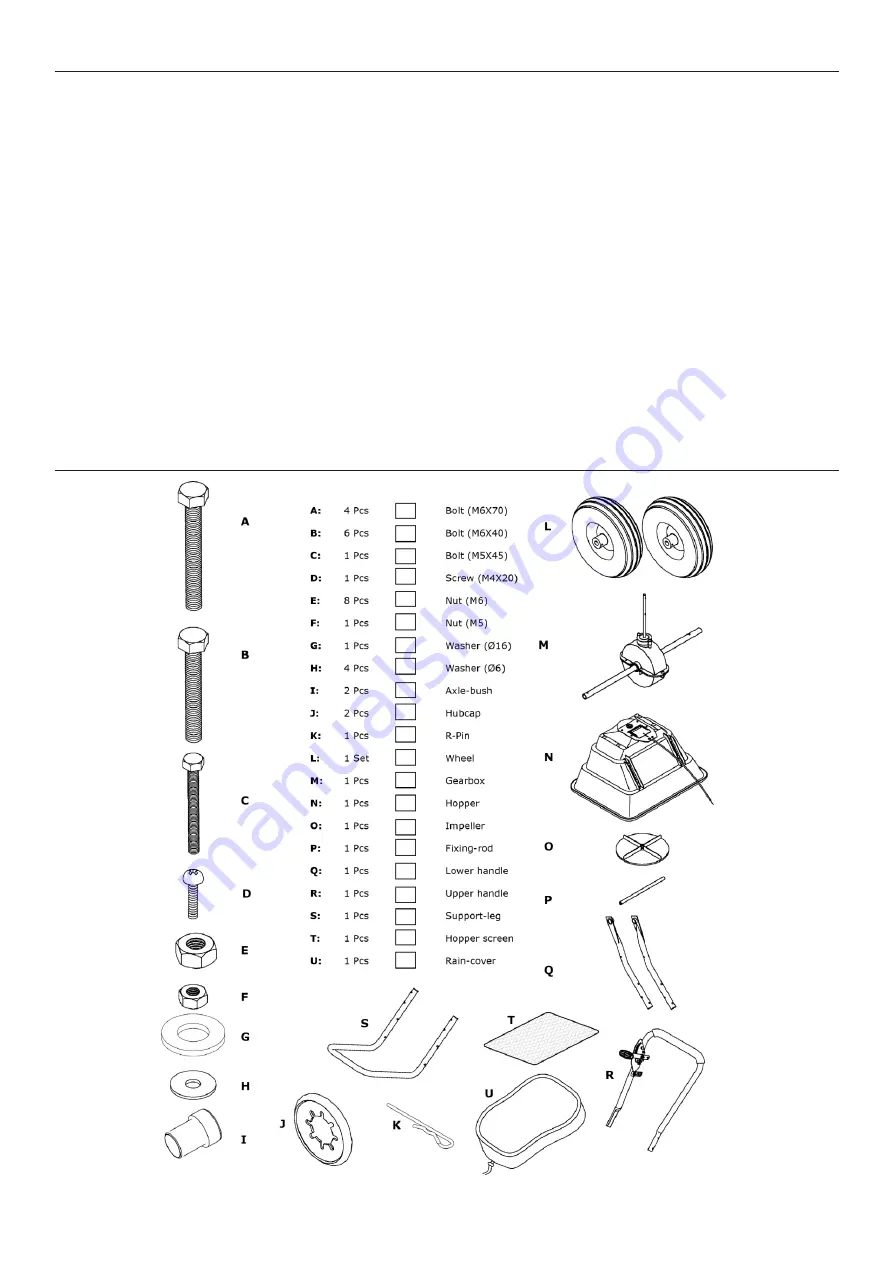

Identification of parts