MAINTENANCE

2-3

Page 2

TESCO EQUIPMENT LLC

ML50-30 MAINTENANCE LIFT

1.

INTRODUCTION

The Tesco ML50-30 Lift is a hydraulically operated, electrically controlled maintenance lift. The

hydraulic and electrical systems require a thorough understanding to determine the cause of a

malfunction or failure of a component. System diagnosis is mandatory to locate a component that is out

of adjustment or has failed.

2.

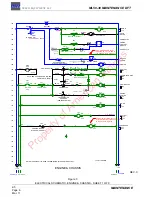

HYDRAULIC SYSTEM

1.

The hydraulic system is an open-center system.

2.

The hydraulic system diagnosis is accomplished by observing the readings on the pressure

gauge or timing a function when a particular hydraulic circuit is actuated. The hydraulic

schematics and adjustment procedures indicate the correct setting for each pressure and flow

adjustment.

3.

The first step in diagnosing a malfunction is to isolate the malfunction to the hydraulic system or to

the electrical control system.

NOTE:

All solenoid actuated control valves in the hydraulic system are equipped with a manual

override that can be used to actuate the valve should there be a loss of electrical current.

The manual override shifts the valve spool and permits oil flow for the Hi-Lift function to

operate. The pressure gauge can be observed for the correct pressure reading for the

system in use.

NOTE:

To obtain oil flow the PTO must be activated with the ENABLE switch. Alternatively, for

test or emergency operation, the hand pump or optional electric auxiliary hydraulic pump

may be used to provide hydraulic flow.

Press both UP switches simultaneously if not equipped with an ENABLE switch. In this

case one of the UP switches function as the ENABLE switch.

3.

ELECTRICAL SYSTEM

The Model ML50-30 has a 12-volt DC electrical system that controls all functions of the Hi-lift. The

components of the electrical system are located in the lower control station, the upper control station,

and the main electrical box. Limit switches in various locations sense a specific position of a mechanical

component for the actuation and interlocking of electrical circuits. The electrical box is located below the

van body usally on the passenger’s side mounted on the hydraulic module. It consists of relays, diodes,

circuit breakers, and terminal blocks. See Chapter 1, Section 2 for the location and function of each of

the separate control stations.

4.

TROUBLESHOOTING GUIDE

The following guide lists Hi-Lift malfunctions and some possible causes for those malfunctions. When

there is a problem or malfunction of the Hi-Lift, read through the list on the left side of the chart. Possible

causes are listed to the right.

Hydraulic component problems are usually caused by oil contamination, and many components can be

made serviceable by a thorough cleaning. Hydraulic filter elements must be replaced when a system

has been cleaned of contamination.

Hydraulic troubleshooting can be done using a pressure gauge and the hydraulic schematics.

Apr. 17

Property of American Airlines