3-5

(2) Be sure to provide pipe supports so that the weight of pipes is not applied directly to the pump

main body.

(3) The suction pipe must be made as short and straight as possible.

(4) Bends must be as far from the suction port of the pump as possible with maximum bend radius.

(5) Carefully attach joints and other parts to the suction pipe to block air suction.

(6) The suction piping should be corresponding to or larger in diameter than the pump port (a size

larger as a guide). In case, for lifting operation, you use a suction pipe with larger diameter than

that of the pump suction port, attach an eccentric reducer to prevent air from being trapped. Also if

you use a suction pipe with smaller diameter than that of the pump, it may cause cavitation.

Note

For the models with pump suction

diameter of 80, 100, and 125mm,

the suction piping should be a size

larger in diameter than the pump. If

you use a suction pipe with smaller

diameter than that of the pump, it

may cause cavitation.

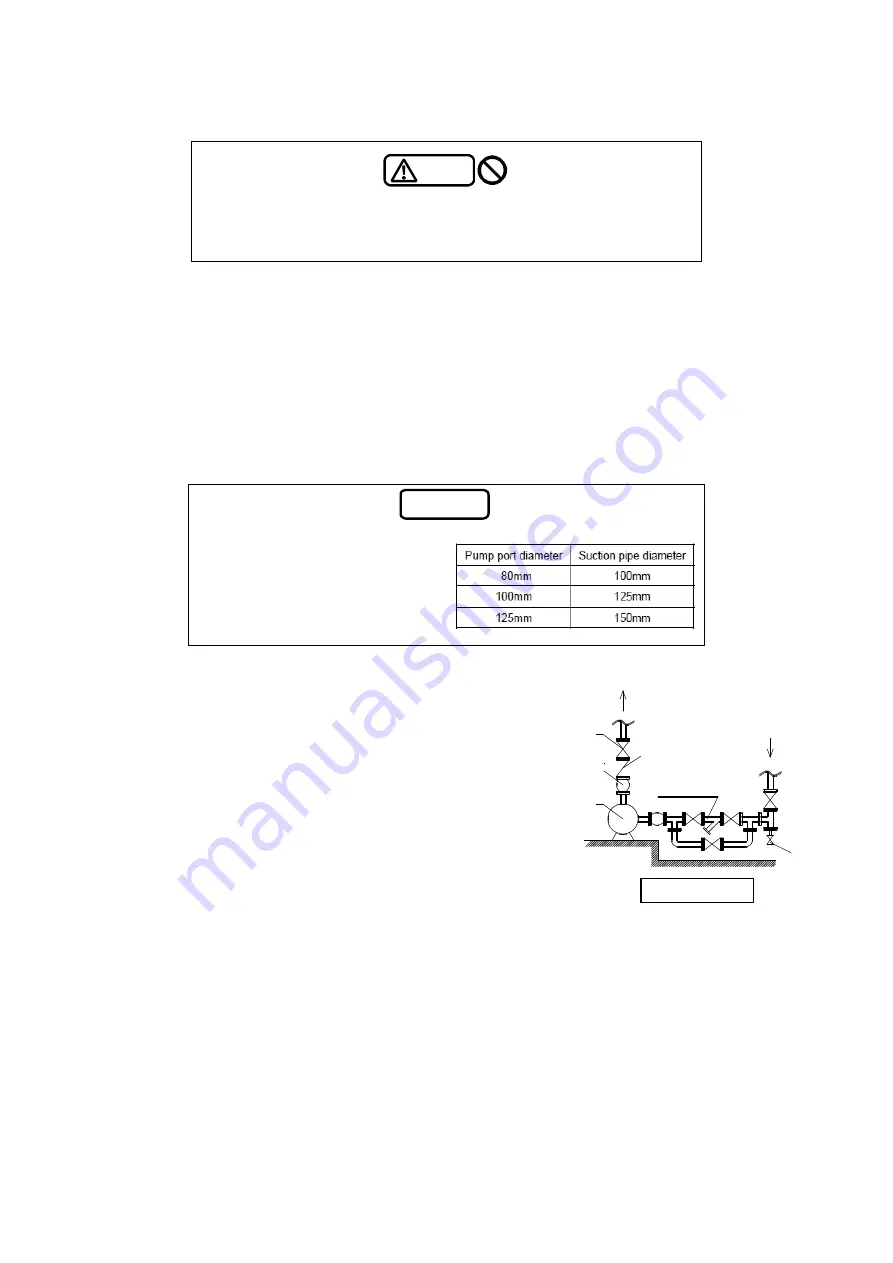

(7) For boost operation

・

Be sure to attach a sluice valve to the suction pipe.

・

Install a strainer at the suction side of the pump to

block the entrance of foreign matter and other

objects (such as cutting chips, sand, rust, and scale)

to the pump. (Recommended mesh size for the

strainer: 40 mesh for normal use, 80 mesh for

cleaning)

(8) For lifting operation

・

The suction pipes should be as short as possible with minimum bends. Do not attach a sluice

valve to the suction pipes. Do not install the piping with a shape of upward bend (i.e. providing

the piping with a rising gradient and then a descending gradient).

・

To prevent air from being trapped inside the suction pipe, provide a rising gradient (at least

1/100 degrees) leading up to the pump.

・

If you use a suction pipe whose bore is larger than that of the suction port of the pump, use an

eccentric reducer to prevent air from being trapped. The diameter of the suction pipe can be up

to 2 sizes larger than that of the pump. (e.g. If the suction port bore of the pump is 40A, the

suction pipe bore must be 50A or 65A.) If the diameter of the suction pipe is too large, the foot

valve might not open or bubbles may easily generate inside the suction pipes due to the

increased amount of the dissolved oxygen.

Caution

Be sure to provide pipe supports for the pipes. Otherwise, the main shaft

may be displaced from the center, thus leading to the equipment damage,

vibration, or noise.

Discharge

Suction

Strainer

Pump

Check

valve

Sluice valve

Drain valve

Vibration

isolation joint

Construction example