TROUBLE SHOOTING GUIDE

WARNING!!! To avoid serious personal injury: Disconnect power before servicing. Electrical service must be

performed by an authorized service station or electrician.

Nothing runs, there is no power.

1.

MAIN switch is off or faulty.

2.

Power cord wire(s) have come loose from

MAIN switch.

3. Fuse blown or circuit breaker tripped in

building.

4.

Short in power cord.

1.

Turn on MAIN switch or replace.

2.

DO NOT USE MACHINE. Have it

paired by an authorized service center or

electrician before using.

3.

Reset breaker and plug machine into a

circuit which is not as heavily loaded.

4.

Replace power cord.

Brush motor does not run.

1.

1.5 amp brush circuit breaker tripped

1.

There are several reasons why this circuit

cause:

breaker could trip:

l

Brush is adjusted too low.

l

See ADJUSTING BRUSH HEIGHT on

page 2.

Brush motor runs but brush does not spin.

l

Brush is clogged with carpet strands or

l

UNPLUG POWER CORD and remove

other debris.

all clogging debris wrapped around

brush.

l

There is

a

dead short in the wiring.

l

DO NOT USE MACHINE. Have it re-

paired by an authorized service center or

electrician before using.

2.

PUMP switch is off or faulty.

2.

Turn on PUMP switch. This switch acti-

vates spray jets and brush drive motor

when you twist roll grips. Replace switch

if faulty.

3.

ROLL SWITCH 1 (left side) needs

3.

Lever on ROLL SWITCH 1 may not be

ment or is faulty.

making contact with roll grip so switch

does not activate when roll grips are

turrned. Bend lever slightly toward roll

grip. If switch is faulty, replace it.

4.

Loose wiring connection or broken wire.

4. DO NOT USE MACHINE. Have it re-

paired by an authorized service center or

electrician before using.

5.

Faulty brush motor.

5.

Replace brush motor.

1.

Brush drive belt is loose or broken.

1.

If belt is loose, loosen brush motor mount-

ing nuts then pivot motor until belt is tight.

If belt is broken, replace.

2.

Set screws for brush pulley or motor pulley

2.

Tighten set screws.

have loosened.

Vacuum motor does not run.

Vacuum motor runs but there is little or no

suction.

1.

VACUUM switch is off.

1.

Turn on VACUUM switch.

2.

VACUUM switch is faulty.

2.

Replace faulty switch.

3.

Loose wiring connection or broken wire.

3.

DO NOT USE MACHINE. Have it re-

paired by an authorized service center or

electrician before using.

4.

Faulty vacuum motor.

4.

Replace vacuum motor.

1.

Recovery tank is full and the auto shutoff

1.

Empty recovery tank.

float has shut off suction.

2.

Vacuum pickup head is clogged.

2.

Raise pickup head and use a coat hanger

or other tool to remove clogging material.

3. Vacuum hose has come loose from

vacuum pickup head.

4.

Vacuum hose has a loose cuff or it has a

hole.

5.

Vacuum hose is not inserted tightly into

clear recovery dome.

6.

Clear recovery dome is loose.

3.

Push hose firmly onto vacuum pickup

head.

4.

Tighten hose cuff or replace hose.

5.

Push hose firmly into dome.

6.

Tighten two knobs on clear dome.

Reverse release lever is hard to engage.

1.

Belt tension is too tight.

1.

Readjust belt tension.

(See Maintenance

Section.)

6

Содержание castex falcon 2800 WF2800

Страница 12: ...CHASSIS PARTS DIAGRAM I 54 45 44 1 y 1 93 28 83 J 103 4 104 F 105 I 106...

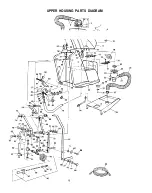

Страница 14: ...UPPER HOUSING PARTS DIAGRAM 3 J7 U J 8 e12 15 I I i 7 332 27 i 65...

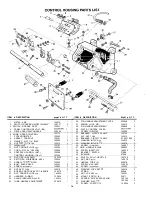

Страница 20: ......