MAINTENANCE

515SS MM419 (1--96)

56

LUBRICATION

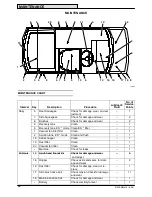

PROPELLING GEARBOX

Check the lubricant level in the propelling gearbox

every 100 hours of operation. Change the gear

lubricant, and the drain and fill-level plug seals

after the first 50 hours of operation, and then

every 1000 hours of operation. Use SAE 90

weight gear lubricant.

FRONT WHEEL SUPPORT BEARING

The front wheel support has two grease fittings for

the bearing. Raise the machine so the front wheel

is off the floor. Fill one of the grease fittings while

rotating the gearbox from stop to stop. Fill the

second grease fitting while rotating the gearbox

back to the original position. The bearing cavity is

full when grease comes out of the fittings, or out

of the top seal.

Lubricate with Lubriplate EMB grease (Tennant

part no. 01433--1) every 100 hours of machine

operation, or after steam cleaning the gearbox

area.

FOR SAFETY: When servicing machine,

block machine tires before jacking

machine up.

FOR SAFETY: When servicing machine,

jack machine up at designated locations

only. Block machine up with jack

stands.

STEERING UNIVERSAL JOINT

The steering universal joint has two grease

fittings. Lubricate with Lubriplate EMB grease

(Tennant Part No. 01433--1) every 100 hours of

operation.

05934

05934

Содержание 515SS

Страница 1: ...515SS MM419 Rev 09 Operator Manual ...

Страница 55: ...OPERATION 53 515SS MM419 9 98 ...