- 2 -

2. INSTALLATION

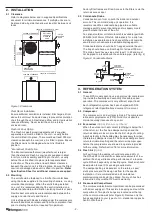

2.1 Clearance

Refer to diagrams below and in supplied Specifications

document for minimum clearances. If multiple units are to

be placed side-by-side then allow at least 2m between coil

faces.

Figure 1. Clearances

Plant Room Installation

Ensure sufficient ventilation is installed. Discharge air from

above the unit must be ducted away to prevent recirculation

of air through the unit. Restricted airflow and/or recirculation

reduces efficiency. Never install the unit in a totally

enclosed room.

Fresh Air Cowl Option

The Fresh Air weathercowl (weatherhood) is supplied

separately and must be fitted to the unit – usually before

the unit is lifted in to place. There must be at least 300mm

clearance beneath the cowl once it is fitted in place. Ensure

the fitted cowl is not damaged when unit is lifted into

position.

*Economiser Cowl Option

The Economiser weathercowl (weatherhood) is larger

than the standard Fresh Air cowl and is supplied in kitset

form for on-site assembly and fitting to the unit – usually

before the unit is lifted into place (refer separate kitset

instructions). There must be at least 300mm clearance

beneath the cowl once it is fitted in place. Ensure the fitted

cowl is not damaged when unit is lifted into position. Refer

Specification Sheet for additional clearances required.

2.2 Mounting

The unit should be fastened to a firm flat horizontal base

using the holes supplied in the mounting channels, or using

universal beam clamps. When the unit is being installed

on a roof it is recommended that the unit is installed on a

substantial structure with vibration isolating mounts or pads.

Flexible duct connections are recommended between the

supply and return ducts and the unit.

Unit is shipped with blocks installed under the compressors.

Ensure these blocks are removed from the compressor feet

prior to starting the unit (not required for operation).

Factory filter frames are fitted. Access to the filters is via the

return air access door.

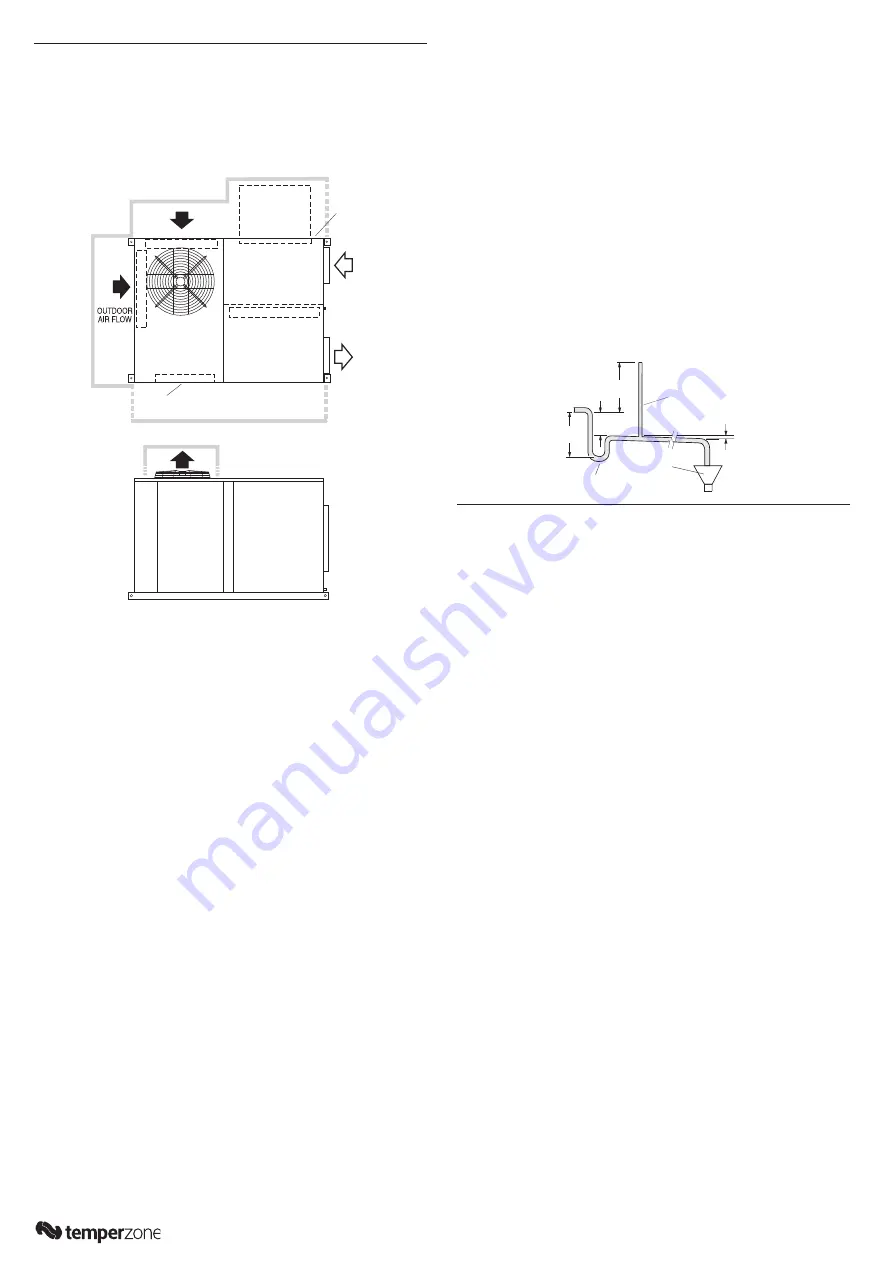

2.3 Condensate Drains

Condensation can form on both the indoor and outdoor

air coils. This is normal during unit operation. It is

recommended the condensate be piped to a suitable

drainage point to prevent ponding and/or slippery mould

growth around the base of the unit.

An optional outdoor coil drain tundish is available (part 060-

000-635) with 25mm OD stub. Alternatively, for a drip free

installation a separate drain tray beneath the unit could be

used to drain condensate to a suitable drainage point.

Condensate drains should be ‘U’ trapped outside the unit.

The trap should have a vertical height of at least 100 mm.

The drain should have a slope of at least 1 in 50 and must

not be piped to a level above the unit drain pipe. (refer fig. 2)

Figure 2. Condensate Drains

OPEN

DRAIN

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

100 mm

MINIMUM

200 mm

APPROX.

'U' TRAP

100 mm

APPROX.

VENT PIPE

FOR LONG

CONDENSATE

DRAIN RUNS

3. REFRIGERATION SYSTEM

3.1 General

These OPA models each have a single inverter compressor

to provide the flexibility and economy of variable speed

operation. The compressor is very efficient at part load.

Each refrigeration system has been charged with R32

refrigerant; refer Specifications document for amount.

3.2 Compressor

The compressor is an inverter scroll type. The compressor

lubricant is polyolester oil (POE). Note, this oil absorbs

moisture quickly if exposed to open air.

3.3 Economiser

(Option) (Controls by Others)

When the outdoor air heat content (enthalpy) is below that

of the return air, the fresh air damper will open and the

return air damper close to provide the first stage of cooling.

A spill air facility in the building may be necessary for when

the return air damper is closed. The fresh air damper should

return to minimum setting and the return air damper open

before the compressors are allowed to operate to provide

further cooling. Refer Section 7.6 for more information.

3.4 Fresh Air

(Option)

Air flow through the damper should not exceed 25% of

the OPA unit’s nominal air flow. Excessive amounts of low

ambient fresh air will reduce the performance of a reverse

cycle OPA unit especially on heating cycle. Fresh air should

be adjusted to meet CO

2

sensing requirements.

The damper setting is dependant on the return air duct

static pressure and the design air flow for the specific

installation. It is recommended an air flow balance

commissioning contractor be utilised. Too much fresh air

introduction may void the OPA unit’s warranty.

3.5 Pressurised Compartment

The compressor/electrical compartment can be pressurised

with indoor supply air. This assists in keeping dust out of the

compartment. Two plastic bungs are located near the top

of the common side-wall (refer Figure 3). Remove only the

bungs applicable to your type of unit – standard or opposite

hand; not both sets.

OPTIONAL

FRESH AIR

WEATHER

HOOD

500 MIN.

CLEARANCE

500 MIN. CLEARANCE

ELECTRICAL

ACESS DOOR

2000 MIN. CLEARANCE

FILTER

ACCESS

DOOR

1000 MIN. CLEARANCE TO UNIT*

1000 MIN. CLEARANCE

FAN ACCESS