instructions.- Insert the new IGBT's between the

dissipator and the spring, taking care not to damage the

component during assembly (the spring should be

inserted under pressure on the dissipator so as to lock the

component);

-

place the dissipators with the new IGBT's and primary

diodes D40 and D41 (

Make sure there is

insulation between the case of diode D41 and the

dissipator) in the PCB bump contacts, placing 4 spacers

between the dissipator and the PCB (2 for each dissipator)

and fasten them down with the screws (torque wrench

setting for screws 1 Nm ±20%);

-

solder the terminals taking care not to let the solder run

along them;

-

on the welding side cut away the protruding part of the

rheofores and check they are not shorted (between the

gate and emitter in particular).

The 4 SECONDARY DIODES are attached to the same

dissipator, and when a replacement is required, all of them

should be replaced:

-

undo the screws attaching the dissipator to the board, to

replace diodes D20, D21, D22 and D23;

-

remove the 4 secondary diodes unsoldering the rheofores

and cleaning any solder from the bump contacts on the

board;

-

remove the dissipator from the board;

-

remove the spring locking the 4 diodes;

-

clean any irregularity or dirt from the dissipator. If the

diodes have burst the dissipator may have been

irreversibly damaged: in this case it should be replaced;

-

apply thermo-conductive grease following the general

instructions;

-

insert the new diodes between the dissipator and the

spring, taking care not to damage the component during

assembly (the screw should be inserted under pressure

on the dissipator so as to lock the component);

-

place the dissipator with the new components in the PCB

bump contacts and fasten them down with the screws

(torque wrench setting for screws 1 Nm ±20%);

-

solder the terminals taking care not to let the solder run

along them;

-

on the soldering side cut away the protruding part of the

rheofores and check they are not shorted (between

cathode and anode);

make sure resistor (R20) and capacitor (C20) on the

snubber have been soldered to the PCB correctly (

).

Whatever fault occurs in the control board, we strongly

recommend its replacement without attempts at repair. To

remove it, cut and then unsolder from the power board the

connector keeping it fixed perpendicular to the PCB, replace it

and re-solder the connector.

Tests should be carried out on the assembled machine before

closing it with the top cover. During tests with the machine in

operation never commute the selectors or activate the ohmic

load contactor.

Before proceeding to test the machine, we

should remind you that during these tests the power source is

powered and therefore the operator is exposed to the danger

of electric shock.

The tests given below are used to verify power source

operation under load.

.

A) Connect the power source to the static load generator

using cables fitted with the appropriate dinse connectors

(code 802110).

B)

C) Set up the multimeter in DC mode and connect the prods

to the OUT+ and OUT- bump contacts.

D) Connect the power supply cable to the 230Vac power

supply.

During tests the operator must avoid contact with

the metal parts of the torch because of the presence of

dangerous, high voltage.

-

activate the statico load generator and make sure that:

- the waveforms displayed on the oscilloscope resemble

those in

;

- the output current is +5Adc±20%, and the output

voltage is +20.2Vdc±20%.

-

deactivate the static load generator and switch off the

main switch.

-

set up the ohmic load with the switch settings as in the

table in

;

-

on the front panel turn the current potentiometer to 75A

(approx. half-way);

-

start up the ohmic load and make sure that:

- the waveforms displayed on the oscilloscope resemble

those in

;

- the output current is equal to +75Adc ±10% and the

output voltage is equal to +24Vdc ±10%.

-

switch off the ohmic load.

WARNING!

B) Please read the procedure for replacing the

secondary board diodes carefully (fig. 4):

N.B.

fig. 3

C) Please read the procedure for replacing the control

board (fig. 3):

WARNING!

WARNING!

A) Minimum

Fig. D

B) Intermediate load test:

fig. E

Fig. E

1.1 Preparation for testing

1.2 Tests for the TECNICA 150 - 170 - 168GE

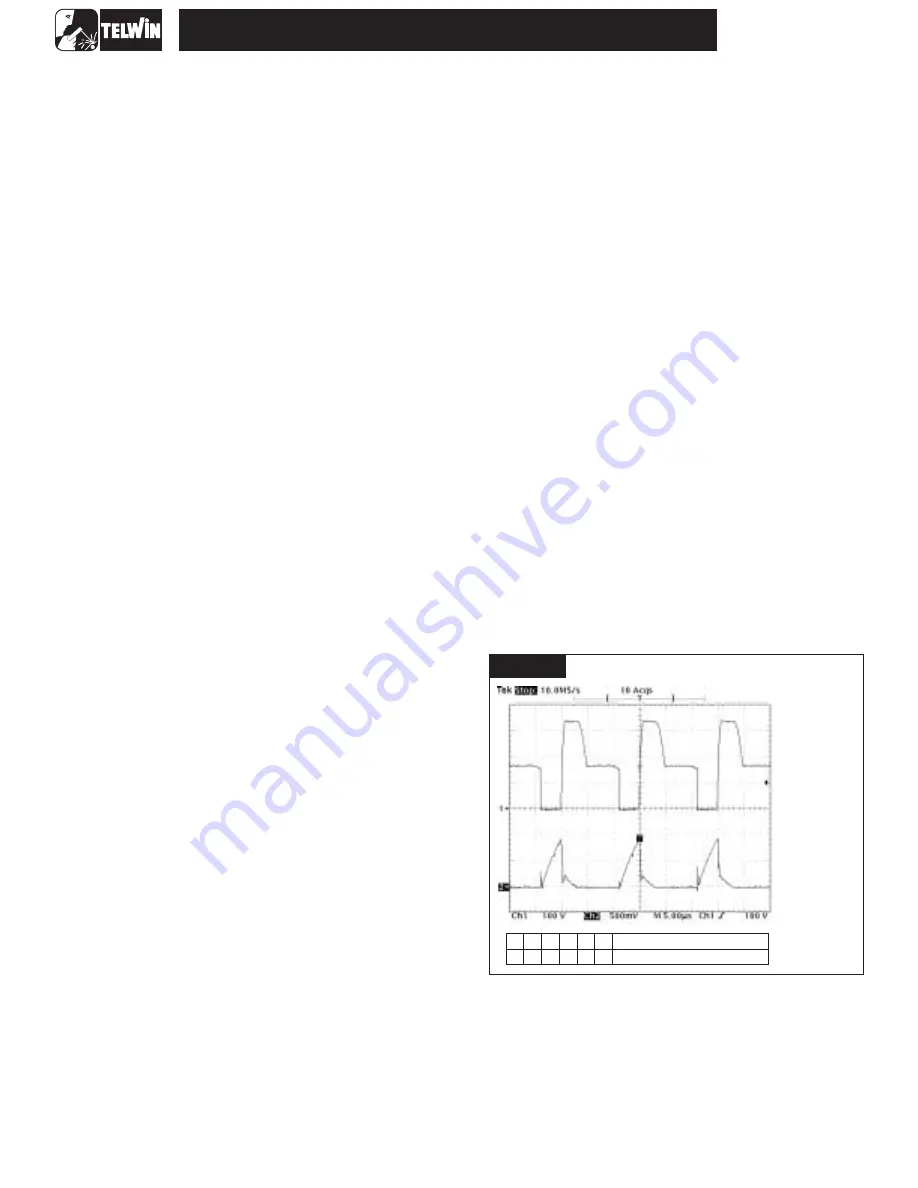

Set up the dual trace oscilloscope, connecting probe CH1

(x100) to the collector on Q1 and probe CH2 (x10) to pin 9 on strip

J11 (plasma control board). The earth terminals are connected

together to the emitter of Q1.

load test:

TESTING THE MACHINE

-

set up the static load generator with the switch settings as

in the table in

;

-

on the front panel position the current potentiometer R23

at (approx.) half way.

-

switch on the main switch;

Fig. D

- 14 -

SETTINGS:

PROBE

PROBE

TIME TOLLERANCES

±20%.

:

AMPLITUDE ON CH1

IS

AMPLITUDE ON CH2

IS

-

CH1 x100

- 100V/Div;

-

CH2 x10;

- 500mV/Div;

- 5 sec/Div.

-

320V ±10%.

-

1V ±10%.

VERIFY THAT

µ

FIGURE D

Position number

Switch number

1

1

2

0

3

0

4

0

5

0

6

0

TECNICA 150-152-170-168GE