Troubleshooting and Service

Teledyne API – Model T108 Addendum to T100 Manual

18

07268C DCN8258

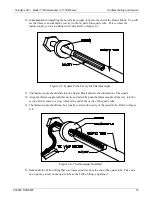

2.5 THERMOCOUPLE REPLACEMENT

Continuous operation at 1000 ºC will eventually degrade the performance of the thermocouple used to

sense the temperature of the quartz oven. The following instructions describe how to install a new

thermocouple into the Converter Heater Block. This is a replacement thermocouple (KIT000255). The

following instructions provide the necessary information to remove the existing thermocouple and replace

it with the new one supplied in Kit 255.

You will need the following tools:

•

Nutdriver,

5

/

16

•

Nutdriver,

11

/

32

•

Diagonal Cutter

•

Philips head Screwdriver #2

You will need to obtain the following replacement parts kit from TAPI:

•

KIT000255 (AKIT, Retrofit, 501TS, TC Type S RPLCMN)

Once you have the right tools and parts, replace the thermocouple as follows:

1. Ensure power is removed from the 501TS Converter. If the Converter has been operational you will

need to wait for 2 hours for the Converter oven to cool before continuing with the replacement of

the thermocouple.

2. Remove the cover from the Converter chassis.

3. Unscrew the (4) nuts that secure the front panel to the chassis. They are located just behind the

Front Panel along the top.

4. Lower the Front Panel to gain easier access to the end of the quartz tube.

5. Unscrew the (3) nuts that secure the inner cover protecting the Heater Block and quartz tube.

Remove this cover.

6. Cut the tie-wrap that secures the thermocouple to the fitting at the end of the quartz tube.

7. Loosen the Teflon fitting at the end of the quartz tube taking care not to put any stress on the tube,

and slide the fitting off the tube.

8. Remove the thermocouple.

9. Disconnect the thermocouple wires from the Temperature Controller.

Figure 2-2. Thermocouple

Содержание T108 Series

Страница 2: ......

Страница 4: ...Teledyne API Model T108 Addendum to T100 Manual ii 07268C DCN8258 This page intentionally left blank...

Страница 6: ...Teledyne API Model T108 Addendum to T100 Manual iv 07268C DCN8258 This page intentionally left blank...

Страница 26: ...Appendix A Model 501 Interconnects 07268C DCN8258...