- Data Brochure

Zone Control 367

D 367

07/95

The Zone Control 367 is a microprocessor-based energy management control that uses PID

logic to control the temperature in up to 6 heating zones. Multiple zone controls can be daisy

chained together for up to 36 zones of heating. The 367 allows a variety of zoning options

including: single stage zones, two stage zones and modulating zones. The 367 is designed

to stagger zone operating times in order to minimize boiler short cycling and allow boiler

purging between cycles. The 367 has a built in night setback timer and a separate Optimum

Start / Stop feature for each zone. When the 367 is used with a tekmar reset control, the 367

provides indoor temperature feedback that adjusts the supply water temperature in order to

satisfy the zone with the highest heat load. Central ventilation, mechanical cooling and free

cooling systems can also be directly controlled through the 367.

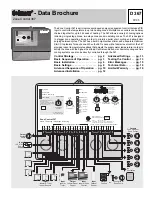

Zone Control 367

One & Two Stage / One Stage & Floating

Power

Heat Required

Zone 2 / Hi stage /

Close / Ventilation

System Pump

24 hr. Timer

• Dial the desired duration

of the UnOccupied period.

• Press start button at the time of day

you want the UnOcc. period to begin.

Timer Active light turns on.

Start

UnOccupied

Duration

0 = always Occupied

24 = always UnOccupied

Zone 1 / Lo stage /

Open / Cooling

2

3

4

1

Zone 4 / Hi stage

Close

Zone 3 / Lo stage

Open

5

6

Zone 6 / Hi stage

Close

Zone 5 / Lo stage

Open

70

°

F

(21

°

C)

40

(4)

100

(38)

UnOccupied

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

0

12 hrs.

24

6

18

Control Strategy . . . . . . . . . . . . . . . .

pg. 2

Advanced Settings . . . pg. 13

Basic Sequence of Operation . . . . .

pg. 3

Testing the Control . . . pg. 13

Basic Installation . . . . . . . . . . . . . . .

pg. 6

Error Messages . . . . . . pg. 15

Basic Settings . . . . . . . . . . . . . . . . . . pg. 9

Technical Data . . . . . . . pg. 16

Advanced Sequence of Operation . . pg. 10

Limited Warranty . . . . . pg. 16

Advanced Installation . . . . . . . . . . . . pg. 12

Zone Control 367

One & Two Stage / One Stage & Floating

H1

121 2

Made in Canada by

tekmar Control Systems Ltd.

N

1

2

3

Pmp

4

Power

L

11 12 13 14

Power

Pump Relay

Zone Relays

120 V 50/60 Hz 8 VA

120 V (ac) 10 A 1/3 hp, pilot duty 240 VA

120 V (ac) 6 A 1/3 hp, pilot duty 240 VA

Aug 95

31000266

24 25

23

26 27

Do not apply power here

21 22

5-6

Com

70

°

F

(21

°

C)

40

(4)

100

(38)

UnOccupied

5

6

7

8 9

10

LR 58223

N R T L / C

R

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

24 hr. Timer

0

12 hrs.

24

6

18

• Dial the desired duration of the

UnOccupied period.

• Press start button at the time of day

you want the UnOcc. period to begin.

Timer Active light turns on.

Start

15 16 17

Com

Sen

RTU

1

RTU

2

Com

Sen

RTU

3

RTU

4

Com

Sen

UnO

Sw

Zo

In

Com

Sen

Out

Sen

20

18

19

5

Caution: Signal wiring must be rated at least 300V

UnOccupied

Duration

0 = always Occupied

24 = always UnOccupied

M

M

M

M

PRGM

S

T I M E

AMPM

UNOCC

OVR

S

M

W T F

T

1

2

LR 58233

E150539

70

70

70

70

Max. Room

40

65

°

F

Off

85

Floating Motor

Speed

130 sec.

30

230

100

200

0

°

F

-40

Off

Design Outdoor

30

Zone 1 Heating

One Stage & Floating

Off

Zone 1 Cooling

Optimum Start

Thermal Motor

Zone

Occ/UnOcc

Zone 2 Ventilating

Zone 2 Heating

1,2

4

3

Occ. only

5 6

One & Two Stage

Power

Heat Required

Zone 2 / Hi stage /

Close / Ventilation

System Pump

Zone 1 / Lo stage /

Open / Cooling

2

3

4

1

Zone 4 / Hi stage /

Close

Zone 3 / Lo stage /

Open

5

6

Zone 6 / Hi stage /

Close

Zone 5 / Lo stage /

Open

Pmp

System

Zo

Out

RTU

5

RTU

6

6

3-4

Com

3

4

1-2

Com

1

2

70

70

LR 58233

E150539

Test

M

M

Input

120 V (ac)

Power

Supply

Input

tekmar Zone

Control

Output

System

Pump

Input

Outdoor

Sensor

Input

tekmar RTUs or

Indoor Sensors

or

Ventilation

Outputs

Zone Valves or

Zone Pumps

Output

Cooling

Input

tekmar

Timer

Output

tekmar Reset

Control

Zone Valve or

Zone Pump

or