13

Floating Action Zones

• If a floating action actuating motor is connected to the terminals

Com 1-2 —1 —2 (19, 20 and 21), make sure power to the motor

circuit is off and install a jumper between the terminals

Com 1-2 — 1 (19 and 20). When the circuit is powered up, the valve should

start to open. If it does not, check the wiring between the terminal and the actuating motor and refer to any installation or

troubleshooting information supplied with the motor. If the valve closes instead of opening, the wiring to the actuating motor must

be reversed. If the valve opens correctly, turn off the power to the circuit and remove the jumper. Install a jumper between the

terminals

Com 1-2 — 2 (19 and 21). When the circuit is powered up, the valve should start to close. If it does not, check the wiring

between the terminal and the actuating motor and refer to any installation or troubleshooting information supplied with the motor.

If the valve closes correctly, turn off the power to the circuit and remove the jumper.

• If a floating action actuating motor is connected to the terminals

Com 3-4 —3 — 4 (22, 23 and 24), follow a similar procedure

to that described above.

• If a floating action actuating motor is connected to the terminals

Com 5-6 —5 —6 (25, 26 and 27), follow a similar procedure to

that described above.

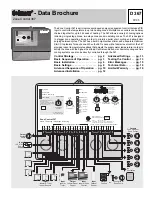

Advanced Settings

Design Outdoor

If the

Design Outdoor dial is turned up from the Off position the Demand Limiting function

is enabled. The

Design Outdoor dial determines the outdoor temperature at which full

heating output is required.

Floating Motor Speed

This dial is used to set the time required for the modulating valve to go from fully closed

to fully open.

Zone 2 Ventilating / Zone 2 Heating

If this DIP switch is set to

Zone 2 Ventilating, the 367 can operate a ventilation system

through output relay

2. If the DIP switches are set to Zone 1 Cooling and Zone 2

Ventilating, the 367 can operate a free cooling system through output relays 1 and 2. If

the DIP switch is set to

Zone 2 Heating the 367 operates output relay 2 as a heating zone.

Testing the Control Functions

STEP SEVEN

OPERATIONAL TEST OF CONTROL FUNCTIONS

The Zone Control 367 has a test routine which is used to test the main control functions. The 367 continually checks the sensors and

displays an error message whenever a fault is found. See page 15 for the list of error messages. When the

Test button is pushed, the

Test light is turned on. The Heat Required, and Optimum Start / Stop lights are turned off and the individual outputs and relays are tested

in the following test sequence.

Test Sequence

Each step in the test sequence lasts 10 seconds. At the end of each step, the device continues to operate

until it is turned off in a later step.

During the test routine, the test sequence can be paused by pressing the

Test button. The test sequence

remains paused at that point for up to 5 minutes. If the

Test button is not pressed again while the test

sequence is paused, the control exits the entire test routine. Once the test sequence is paused, the

Test

button can be pressed again to skip to the next step. This can also be used to rapidly skip through the test

sequence. To reach the desired step, repeatedly press and release the

Test button until the appropriate

device and indicator light turn on.

Step 1 - The System Pump relay is turned on.

Step 2 - If the Com 5-6 common block is used for a single One Stage zone, the control

turns on relay

5 for 10 seconds.

- If the

Com 5-6 common block is used for two One Stage zones, the control turns

on relay

5 for 10 seconds and then turns off relay 5 and turns on relay 6 for

10 seconds.

- If the

Com 5-6 common block is used for a Two Stage zone, the control turns

on relay

5 and then, after 10 seconds, turns on relay 6.

- If the

Com 5-6 common block is used for a Floating zone, the control turns on

relay

5 for 10 seconds and then turns off relay 5 and turns on relay 6 for

10 seconds.

- If an RTU is not connected to

RTU 5 or RTU 6 , the control skips this step.

1

2

1

System Pump

5

Zone 5 / Lo stage /

Open

Zone 6 / Hi stage /

Close

6

4

Zone 4 / Hi stage /

Close

3

Zone 3 / Lo stage /

Open

2

Zone 2 / Hi stage /

Close / Ventilation

Zone 1 / Lo stage /

Open / Cooling

1

System Pump

Test

Zone 1 Cooling

Zone 2 Ventilating

Floating Motor

Speed

130 sec.

30

230

100

200

0

°

F

-40

Off

Design Outdoor

30