tekmarNet

®

2 House Control 400

D 400

09/13

HVAC Systems Replaces: 09/10

Installation & Operation Manual

© 2013

400_D - 09/13

1 of 32

Menu

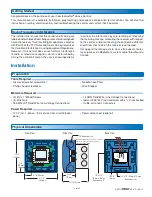

House Control 400

Item

VIEW

Boil Exp Boil System

Zones

1 2 3 4

Calls

Pumps

Benefi ts

Energy efficiency through Outdoor Temperature

Reset with Indoor Feedback

Indoor Feedback minimizes the water temperature

(increasing energy savings), and the efficiency of

your mechanical equipment through integrated

tekmarNet

®

Thermostats

Zone Synchronization reduces equipment cycling

Auto Differential - Reduces boiler cycling

Compact enclosure for flexible installation

Simple zone expansion using Wiring Centers

•

•

•

•

•

•

The tN2 House Control 400 is designed to operate all

of the mechanical equipment in a residential hydronic

heating system, coordinating their operation with network

communication. It can be used in applications ranging

from a single zone of baseboard with an on/off boiler, to

multiple radiant floor zones with a modulating/condensing

boiler. This control regulates one space heating water

temperature through Outdoor Temperature Reset and

Indoor Temperature Feedback. It is capable of controlling

a single on/off, two stage, or modulating boiler, Domestic

Hot Water, setpoint loads, 4 on-board zone valves, and

can expand up to 24 zones in total.

Features

Automatic Boiler Differential

Boiler Protection

DHW Post Purge

DHW Priority (optional)

DHW control

Exercising

For use with tekmarNet®2 thermostats ONLY

Four 24 V (ac) powered zone outputs

Indoor Temperature Feedback

One touch overrides (with optional User Switch)

Only requires 2 Wires Per Zone

Outdoor Temperature Reset

Powered pump outputs

Setpoint operation

Single on/off, two stage, or modulating boiler

control

System Setback (with optional Timer)

Warm Weather Shut Down

Zone Synchronization

tN4 expansion terminals

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Introduction