MAINTENANCE

The arm DOES NOT need maintenance and it is difficult to have anomalies if you make a

correct use of it, although we specify the main and easy repairs that you can do.

DAMPER REPLACEMENT

1. Let down the damper regulating assembly (1), located below the cross unit.

2. Take out the headmember (2).

2.1. Remove the screws that hold the headmember to the arm

2.2. Use the screw M5 to take out the stay spindle (figure 2). For doing this operation,

the arm must be located in its lowest position. Then, loosen the screw rod (located

below the headmember) that fixes the stay spindle.

3. Take out the spindle of the arm damper (4).

4. Take up the damper regulating assembly.

5. Take out the damper (5).

6. Reverse the process for the reassembling.

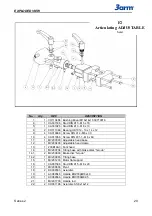

Figure 1

Figure 2

Содержание 3arm 2 Series

Страница 7: ...ARM and HEADMEMBER SELECTION Series 2 7 METRIC KG ...

Страница 12: ...EXPLODED VIEW ...

Страница 14: ...EXPLODED VIEW Series 2 14 ...

Страница 25: ...NOTES DATE DESCRIPTION ...