38

Section 6

:

Cleaning

To ensure the opti mum print qualit y, precision component s and electr onic parts

are used for t his printer. Stai n on rollers and print head is cr ucial to the

pri nt qualit y. To maintai n the best print condit ions, observe the following point

Clean these part s periodicall y to keep the opti mum perfor mance.

□

Turn OFF the power without fail before the cleaning operation.

→

It may cause a trouble and/or to have electrical shock.

□

Do not use solvents other than

alcohol for cleaning OA equipments

.

→

Using the solvent other than alcohol may damage the parts and may cause

trouble of the printer.

□

Do not clean the parts at near the fire.

→

Alcohol is flammable and may cause fire accident.

□

Take off all the cards on feeder block before c leaning

→

In case of the roller in the feeder block rotate linking with other rollers

It may cause a trouble.

□

Take off all the cards on feeder block before cleaning

→

In case of the roller in the feeder block rotate with linking to other rollers

It may cause a trouble.

□

After the cleaning operation, leave the machine for about 5 min before

restarting.

→

Correct printing may not be obtained if printed before the alcohol is

completely dried.

□

Do not touch the rollers with hand.

→

Fingerprint may affect the quality of the printed image.

□

Take off all the cards on feeder block before cleaning

→

In case of the roller in the feeder block rotate linking with other rollers

It may cause a trouble.

Although the i nterval of cleaning varies dependi ng on t he conditi on of the card,

the following period is recommended assumi ng t hat the car ds are properl y stored

and handled.

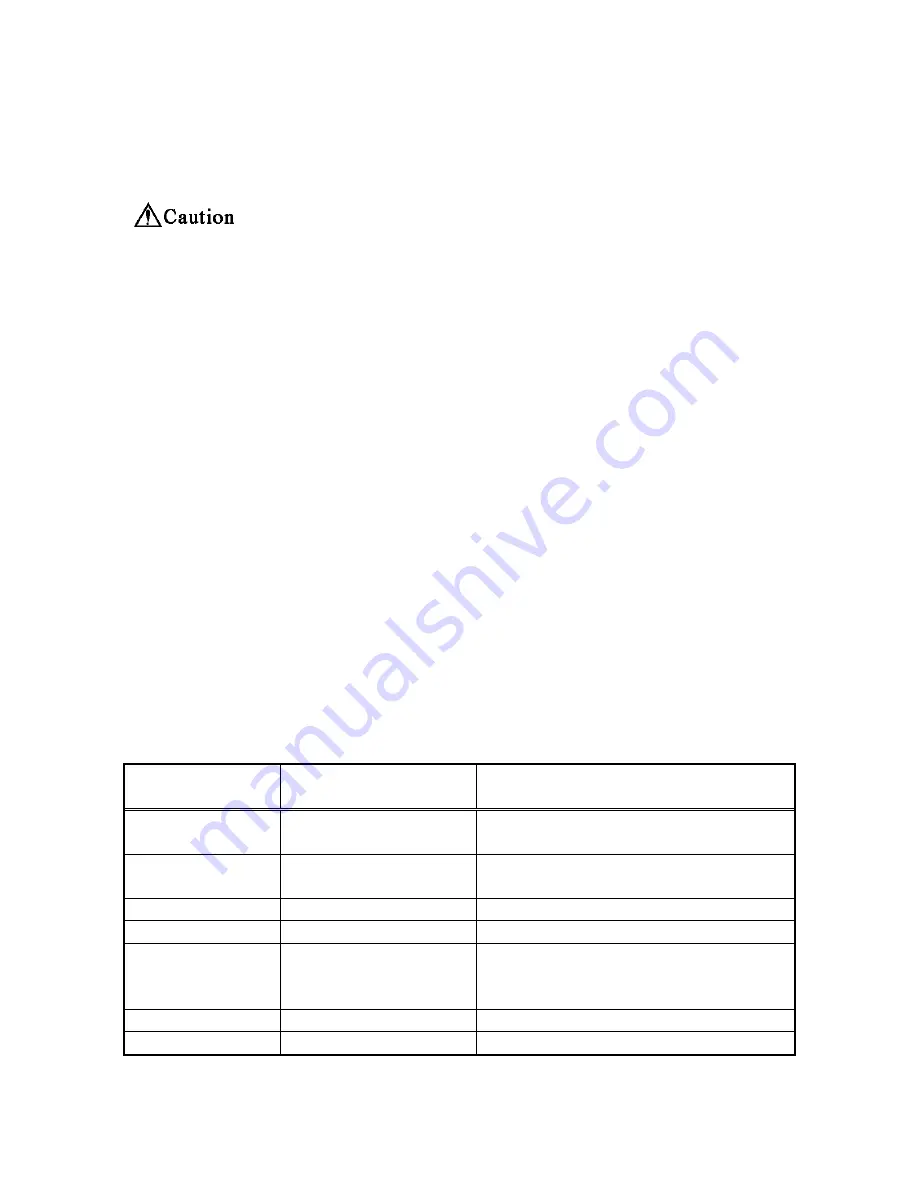

Parts to be

cleaned

Number of

frames printed

Cleaning tools and solvent

Input Roller

Every 2000 frames

Soft cloth with no fur, Alcohol

Ribbon Transp-

ortation roller

Every 10000 frames

Soft cloth with no fur, Alcohol

Exit Roller

Every 10000 frames

Cotton swab, Alcohol

Print Roller

Every 10000 frames

Cleaning brush, Alcohol

Transportation

Roller on F/T

Block

Every 10000 frames

Cotton swab, Alcohol

Supply Roller

Every 10000 frames

Soft cloth with no fur, Alcohol

Pr i nt Head

Every 2000 frames

Soft cloth with no fur, Alcohol

Number of the frames printed is indicated by the counter on the operation panel.

→

Refer to Section 4 "Operation of the User Mode".

Содержание Nisca PR5350

Страница 1: ...DIRECT CARD PRINTER Operation Manual Ver 1 3 FEB 11...

Страница 20: ...17 Front Access Panel Input Roller Module Ribbon Cartridge Holding Lever Manual Rotation Knob Ribbon Cartridge...

Страница 36: ...33 OFF A Back Side Hold Card Error Top OFF OFF ON ON Lo Co Face Up Edge to Edge...

Страница 47: ...44 MEMO...

Страница 50: ...47...

Страница 59: ...56 Block Layout...

Страница 64: ...61...