409-35011

Rev C

44

of 54

(6) Place the new Mandrel into the changeover tool (see Figures 46), insert the tool and Mandrel

into the Mandrel Shaft, turn the tool clockwise to tighten the mandrel.

CAUTION

DO NOT OVERTIGHTEN.

(7) Remove LOTO from the machine.

(8) Apply power to the machine.

(9) Perform the Calibration Cycle

9. Calibration Cycle:

a. The HV-CP automatically calibrates the tooling to ensure the proper tooling set for the application

are installed.

b. To calibrate, press the button on the UI, and the machine will run the cycle.

NOTE

It is recommended that this be done every time any of the tooling is replaced.

10. Tooling Changeover for 50-60 mm

2

size cables:

a. Due to the variance in the cable diameters, the machine will select the most appropriate tooling for

the diameters provided. However, there is an opportunity to select another set of tooling.

(1) Some smaller 60 mm

2

cables will be in the 50 mm

2

tooling range and will therefore work with

both sets of tooling.

CAUTION

If you select the wrong tool, there is a potential for tooling crash or scrapped cables.

Preventive

The machine has been designed to minimize maintenance as much as possible. The following preventive

maintenance procedures should be done on the intervals given below.

DANGER

Always turn off and lock out the Main Disconnect and the Pneumatic shutoff when performing maintenance on the

HV-CP machine.

By Schedule

Inspect the belts for cracking, missing teeth, or missing pieces every 250K cycles.

6.

TROUBLESHOOTING

Perform troubleshooting in accordance with Figure 47.

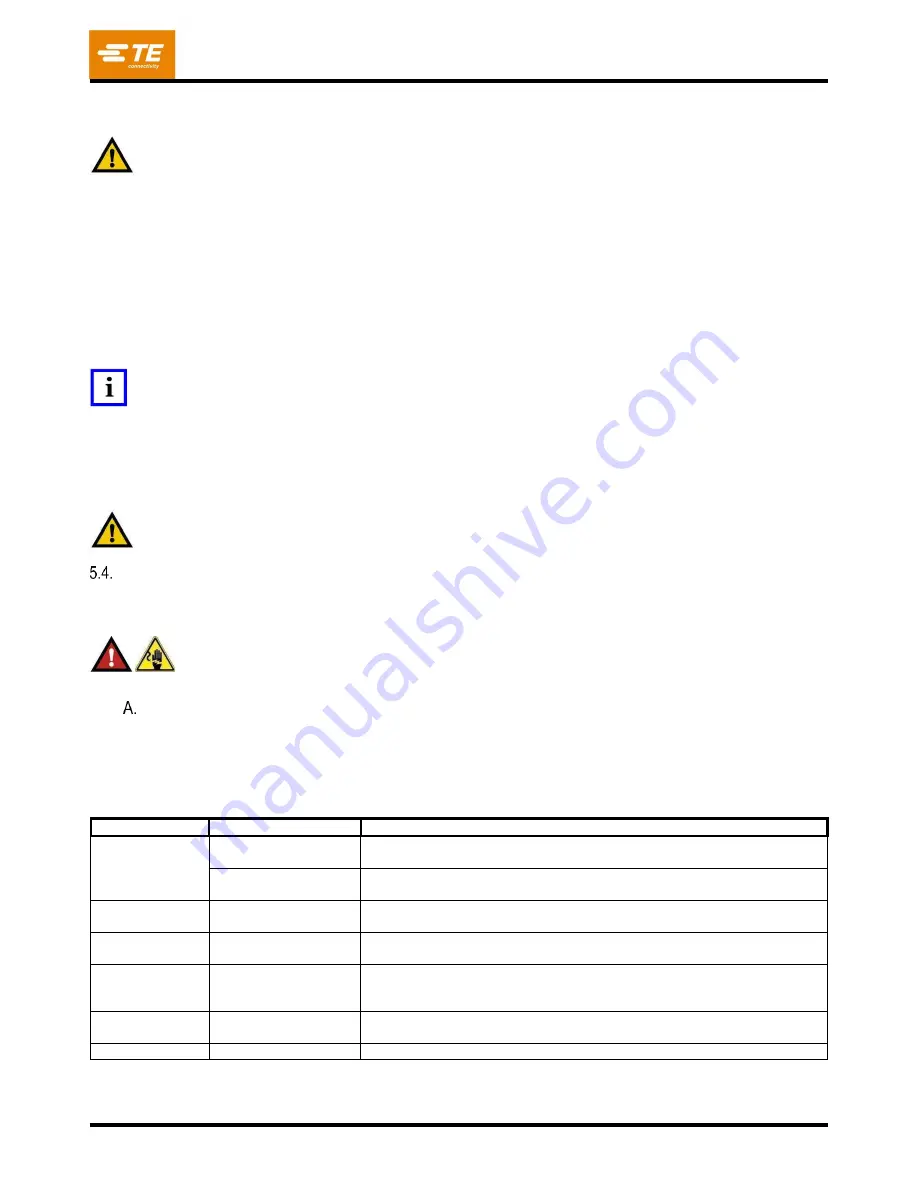

Problem

Probable Cause

Solution

Cable not feeding

properly

Cable end out of round

Cut the end of the cable again if the cable is severely out of round. Otherwise, squeeze the

cable in your hands to return the cable to a round shape.

Cable not straight enough

–

not touching sensor

Remove cable and restraighten. Re-insert cable and point any bend upwards if possible

(gravity will help straighten cable).

Scrap Tube Clog

Bin Full or an obstruction in

Tube

Empty Bin and/or clear obstruction from the scrap tube by removing the bin and clearing the

scrap above.

Mis-shaped or poor

cuts

Dull tooling

Replace tooling.

Improper Cut

Rotary Head not Homing

Verify homing performance by inserting tooling change tool 2361560-1 into the hole in the

pulleys when homed (If the machine has properly homed, the pin will smoothly slide into the

pulleys).

Sequence not

correctly performed

----

Contact TE Field Service Engineering for assistance.

Loss of cycle data

----

Back up on flash drive or contact TE Field Service Engineering for assistance.

Figure 47