408-9279

Rev F

4

of 7

4. Make sure the ratchet is released. Squeeze the tool handles together and allow them to open fully.

5. Rotate the blue plastic locator stop index to the appropriate position.

When crimping a 110 Series terminal, rotate the index until the number

“110”

appears in the

uppermost position.

When crimping a 187 or 250 Series terminal, rotate the index until the numbers

“250

-

187”

appear in

the uppermost position.

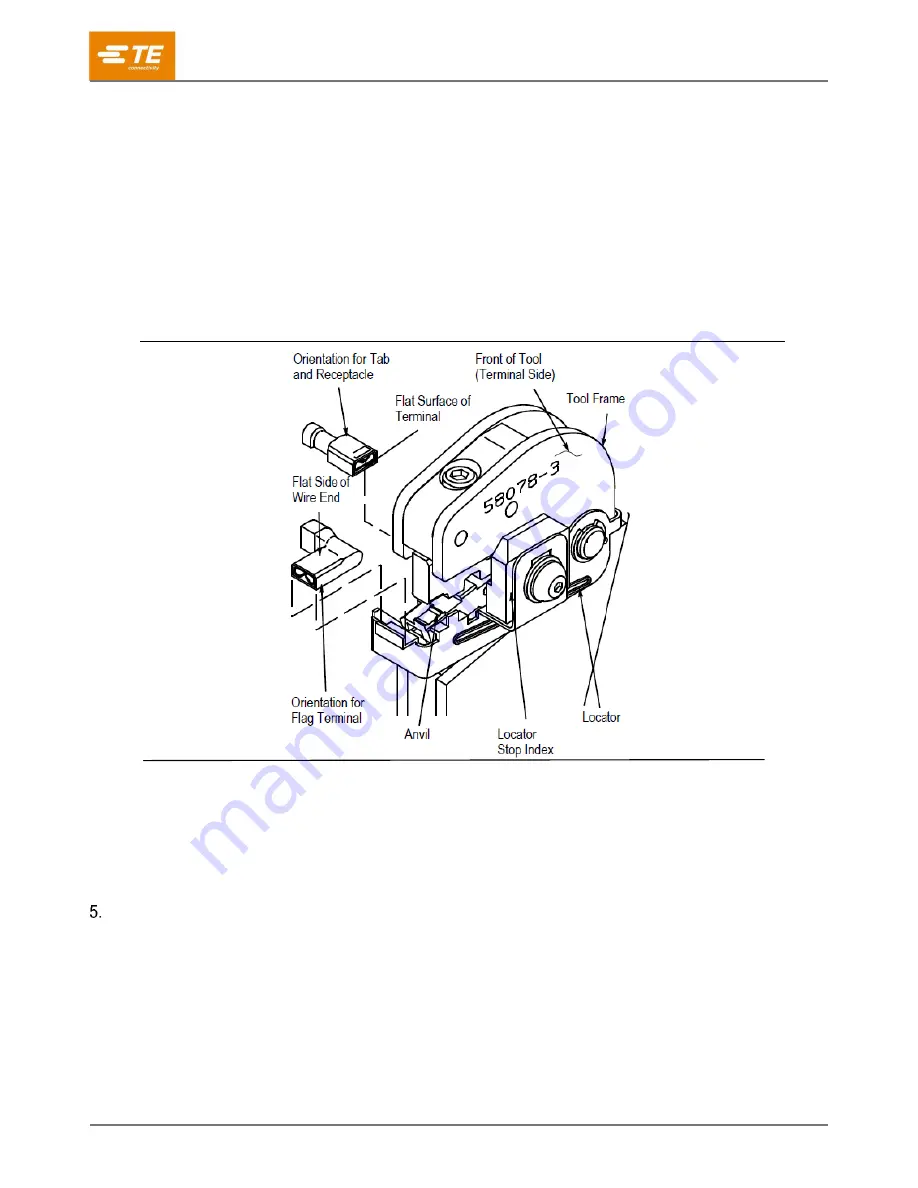

6. Insert the terminal into the proper crimp section.

In-line terminals may be crimped in either in-line section.

Flag terminals must be crimped in the flag crimp section (see Figure 4).

For in-line terminals, the flat side of the terminal must seat on the locator.

For flag terminals, the flat side of the wire end must face outward and the mating end must seat on

the locator.

Figure 4

7. Squeeze the tool handles sufficiently to hold the terminal firmly in place without deforming it.

8. Insert a properly stripped wire into the barrel of the terminal.

9. Hold the wire in place and squeeze the tool handles until the ratchet releases.

10. Allow the tool handles to open fully and remove the crimped terminal.

MAINTENANCE/INSPECTION

5.1.

Daily Maintenance

Remove all foreign particles with a clean, soft brush or a clean, soft, lint-free cloth. Do NOT use materials or

objects that can damage the dies. If foreign matter cannot be removed easily, or if the proper replacement parts

are not available, return the dies to your supervisor.

Make certain the dies are protected with a THIN coat of any good SAE 20 motor oil. DO NOT OIL

EXCESSIVELY.

When the dies are not in use, mate them and store in a clean, dry area.

SAE is a trademark