408-1745

4

of 7

Rev

D

4. Activate the power unit to complete the crimp.

5. To complete the other half of the butt splice,

remove and reposition the uncrimped half of the

splice in the nest. Insert the wire and then activate

the power unit to crimp the splice. The completed

terminal or splice should be as shown in Figure 5.

7. INSPECTION/MAINTENANCE

DANGER

Make sure hydraulic pressure is released and power

supply is disconnected before following inspection and

maintenance procedures, unless otherwise specified in

the procedure.

Each crimping head is assembled and inspected

before shipment. It is recommended that the crimping

head be inspected immediately upon its arrival at your

facility, and at regularly scheduled intervals, to ensure

that the crimping head has not been damaged during

handling. Frequency of inspection depends upon the

following: care, amount of use, and handling of the

head; type and size of products crimped; degree of

operator skill; and environmental conditions.

7.1. Cleaning

Remove accumulations of dirt and grease on the

crimping head, especially in areas where dies are

installed and terminals are crimped. Clean the entire

head frequently with a clean, lint-free cloth.

7.2. Visual Inspection

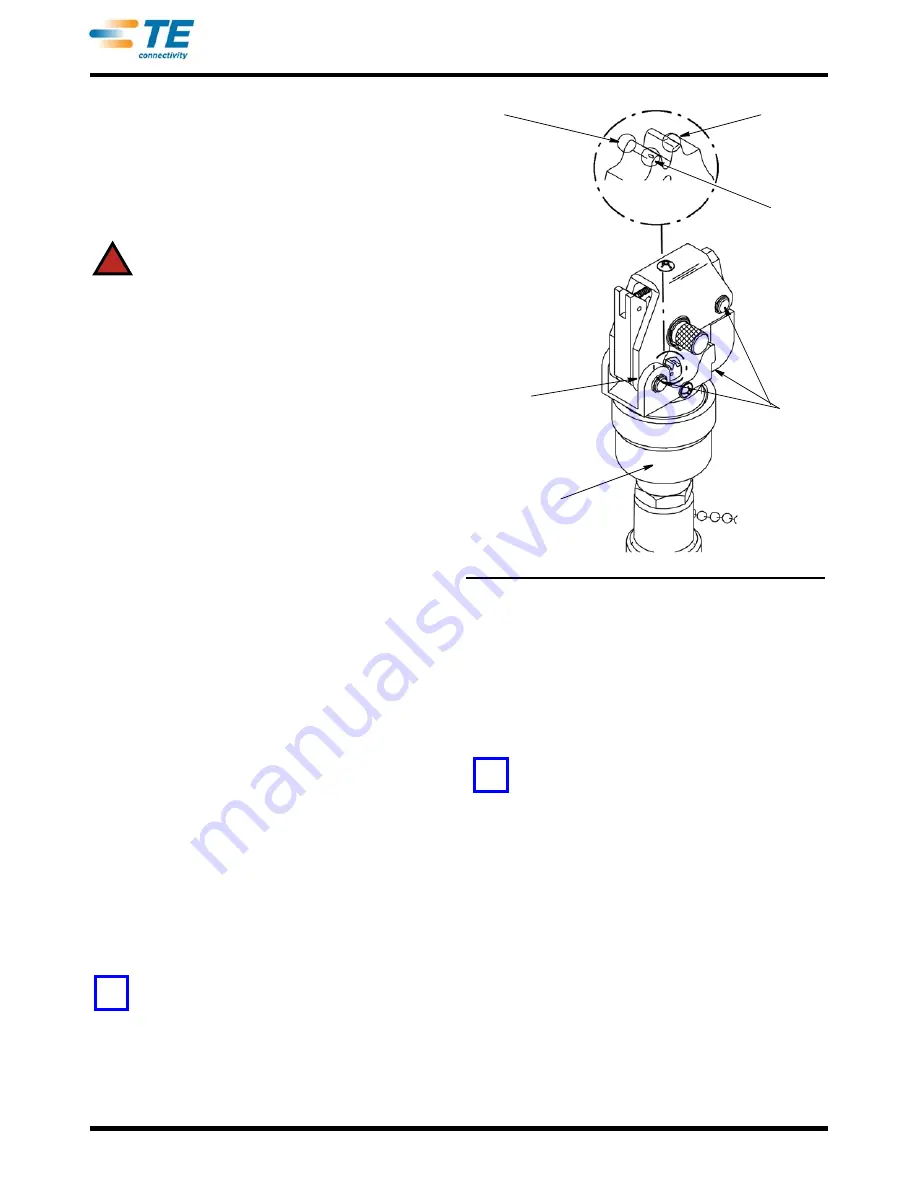

Refer to Figure 6 and proceed as follows:

Chipped

Area

Flattened

Area

Pitted

Area

Check for

Excessive Wear

at all Pivot Points

Check These

Areas for Cracks

Check These

Areas for Cracks

1. Visually inspect die closure surfaces for chipped,

pitted, or flattened areas.

2. With hydraulic pressure released, inspect the

assembled head for nicks, scratches, and cracks.

Inspect for cracks especially at the corners of the

yoke and around the top of the cylinder.

3. Inspect pivot pin holes and latch pin holes for

wear. Replace parts, as needed.

4. Activate power unit. Raise ram to UP position.

Inspect flat and round surfaces of ram for galling

(fretting or wear by friction), cracks, or oil leakage.

Release pressure and make sure that ram retracts

smoothly.

5. If head shows evidence of galling, cracks, oil

leakage, or rough cycling, return the crimping head

to for repairs. (Refer to Section 8, REPLACEMENT

AND REPAIR).

NOTE

I

t is recommended that the head be returned to TE after

every two years (or every 50,000 cycles) for magnetic

particle inspection. Refer to Instruction Sheet 408-9684.

Figure 6

7.3. Die Closure Inspection

Every crimping head die set is inspected for proper die

closure before shipment. However, the dies should be

inspected for excessive wear periodically. Die closure

is accomplished using GO/NO-GO plug gages.

Suggested plug gage design and GO/NO-GO

dimensions are shown in Figure 7.

NOTE

TE neither manufactures nor sells plug gages. Refer to

408-7424 for gaging information.

1. Clean the oil and dirt from the closure surfaces,

and plug gage members.

2. Lock the desired nest in the crimp position and

raise the indenter to the full UP position, as shown

in Figure 8, Detail A.

3. With the indenter positioned at the full UP

position, inspect the die closure using the

appropriate plug gage. Hold the gage in alignment

with die closure and carefully insert, without forcing,

the GO member. See Figure 8. The GO member

must pass completely through the die closure as

shown in Figure 8, Detail B.

4. Try to insert the NO-GO member. The NO-GO

member may enter partially, but must NOT pass

completely through the die closure. See Figure 8,

Detail B.

!

NOTE

i

NOTE

i