409- 10065

Rev F

6

of 9

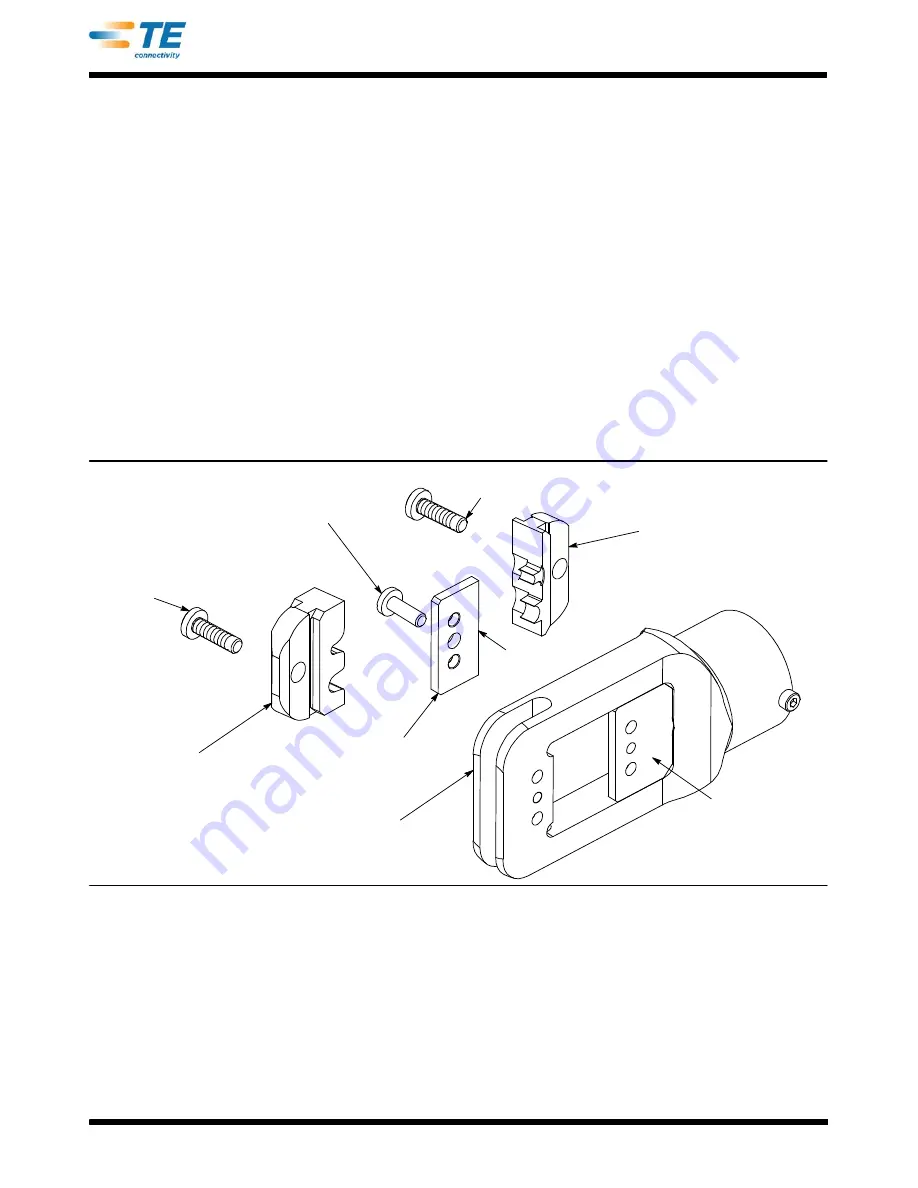

A. Installation of Shouldered Dies

(Figure 2 )

1. Remove the battery from the tool.

2. Remove the two die retaining screws from the crimp head.

3. Remove the ram plate from the moving jaw.

4. Place the upper die in the upper portion of the tool head so that the largest indenter is on the right.

5. Insert the die retaining screw through the upper jaw and through the die. Tighten the screw

just

enough

to hold the die in place. Do

NOT

tighten the screw completely at this time. See Figure 2.

6. Place the lower die in the moving jaw of the crimp head so that the largest anvil is on the right.

7. Place the ram plate on the moving jaw. The chamfers on the corners of the ram plate should be

located adjacent to the die set.

8. Insert the die retaining screw through the ram plate; die set, and the moving jaw. Tighten the screw

just enough

to hold the die in place. Do

NOT

tighten the screw completely at this time.

9. Replace the battery and pulse the trigger to slowly close the crimp head, making sure the anvils and

indenters are properly aligned.

10. When the anvils and indenters are aligned, tighten the retaining screws.

Figure 2

Upper Die

Retaining

Screw

Upper SDE Die

Lower Die Retaining Screw

Lower SDE Die

Moving Jaw

Upper Jaw

Ram Plate

Machine Screw

Chamfer on

Ram Plate