33

Model C043

Operating Procedures

Cleaning

IMPORTANT: Failure to follow these

cleaning procedures may result in bacterial

contamination of the frozen custard product.

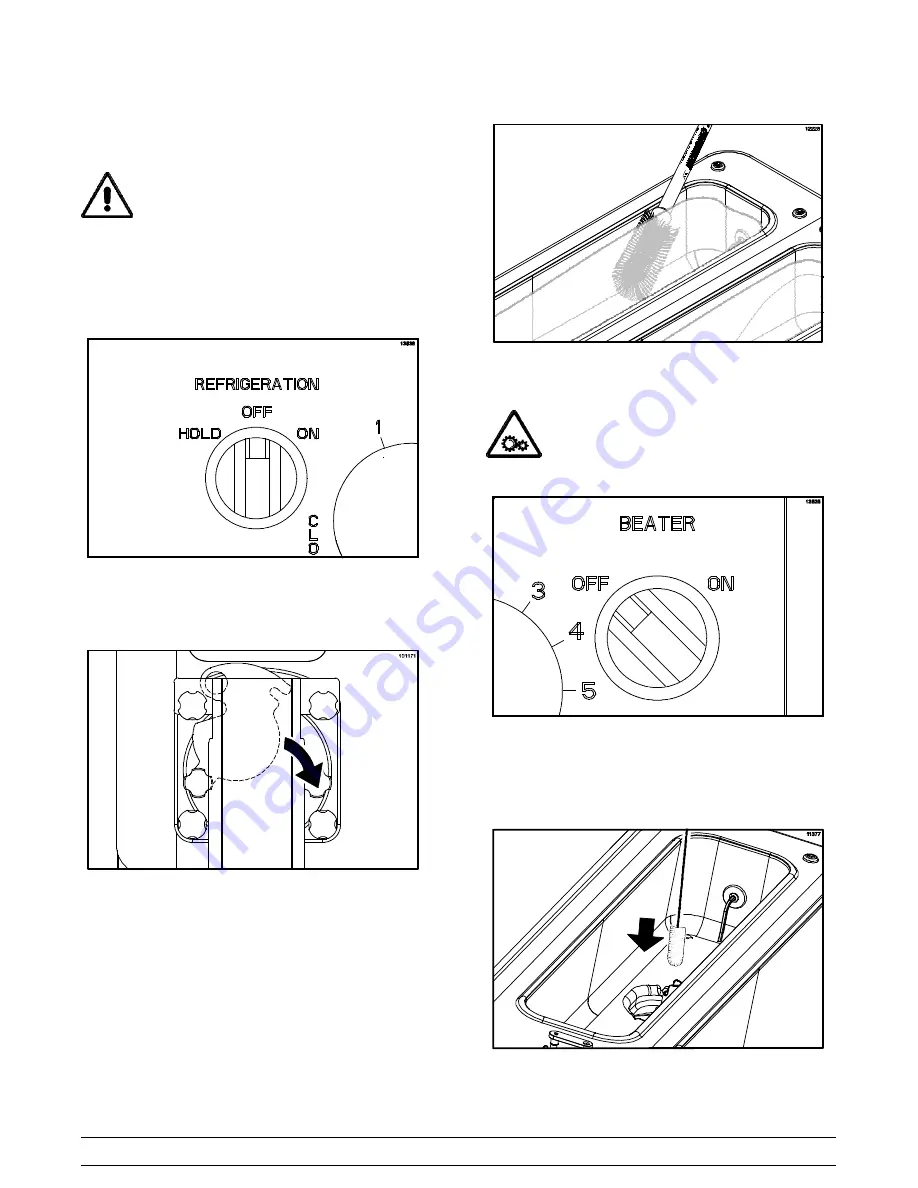

Step 1

Make sure the refrigeration switch is in the “OFF”

position.

Figure 80

Step 2

Close the draw arm plate.

Figure 81

Step 3

Using

lukewarm

water, prepare an approved 100

PPM sanitizing solution (examples: 5 gal. [19 liters]

of Kay-5

R

or 4 gal. [15 liters] of Stera-Sheen

R

).

USE WARM WATER AND FOLLOW THE

MANUFACTURER'S SPECIFICATIONS.

Step 4

Pour the cleaning solution into the hopper. Brush

clean the sides and bottom of the hopper.

Figure 82

Step 5

MAKE SURE THE BEATER SWITCH IS

IN THE “OFF” POSITION.

Figure 83

Step 6

Using the draw valve brush (1” x 2” x 17”), clean the

mix inlet hole.

Figure 84

Содержание Model C043

Страница 1: ...Model C043 General Market Custard Machine Operating Instructions 068359 M 7 22 10 ...

Страница 11: ...7 Model C043 Safety Notes ...

Страница 12: ...8 Model C043 Operator Parts Identification Section 4 Operator Parts Identification C043 Figure 1 ...

Страница 14: ...10 Model C043 Operator Parts Identification Beater Door Hopper Assemblies Figure 2 ...

Страница 57: ...C043 063943 33A Rev 7 10 ...

Страница 58: ...C043 063943 33B Rev 7 10 ...