6-10

OPERATING PROCEDURES

087482-M

Operating Procedures

6

Cleaning

1.

Prepare an approved 100 PPM cleaning solution

(examples: 2.5 gal. [9.5 L] of Kay-5

®

or 2 gal. [7.6 L]

of Stera-Sheen

®

).

Use warm water and follow the

manufacturer's specifications

.

2.

With the prime plug down, pour 1 gal. (3.8 L) of

cleaning solution into the mix hopper and allow it to

flow into the freezing cylinder.

3.

While the solution is flowing into the freezing cylinder,

brush clean the mix hopper, the mix inlet hole, and

the mix level probe.

4.

Press the WASH key to cause the cleaning solution

in the freezing cylinder to agitate.

5.

Place an empty pail beneath the door spout and raise

the prime plug. When a steady stream of cleaning

solution is flowing from the prime plug opening in the

bottom of the freezer door, open the draw valve.

Draw off all of the solution.

6.

Once the cleaning solution stops flowing from the

door spout, close the draw valve, push the prime plug

down, and press the WASH key cancelling the

WASH mode.

7.

Repeat step 1 through step 6 for the other side of the

machine.

Disassembly

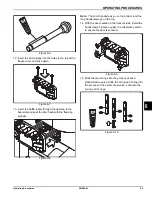

1.

Remove the handscrews and the freezer door.

Remove beaters, scraper blades, and drive shafts

from the freezing cylinders. Take these parts to the

sink for cleaning.

2.

Remove the front drip tray, splash shield, and drip

pans from the machine. Take them to the sink for

cleaning.

3.

Remove the rear drip pan and take to the sink for

cleaning.

Note:

If the drip pan was filled with an excessive amount

of mix, the drive shaft O-ring of the beater assembly

should be replaced or properly lubricated.

Brush Cleaning

1. Prepare a sink with an approved cleaning solution

(examples: Kay-5

®

or Stera-Sheen

®

).

Use warm

water and follow the manufacturer's

specifications

.

Important!

Follow label directions. Too

strong

of a

solution can cause parts damage, while too

weak

of a

solution will not provide adequate cleaning. Make sure all

brushes provided with the machine are available for

brush cleaning.

2. Remove the seals from the drive shafts.

3. From the freezer door, remove design caps, pivot

pins, draw handles, gaskets, front bearings, prime

plugs, and draw valves. Remove all O-rings.

Note:

To remove O-rings, use a single-service towel to

grasp the O-ring. Apply pressure in an upward direction

until the O-ring pops out of its groove. With the other

hand, push the top of the O-ring forward; it will roll out of

the groove and can be easily removed. If more than one

O-ring needs to be removed, always remove the rear

O-ring first to allow the O-ring to slide over the forward

rings without falling into the open grooves.

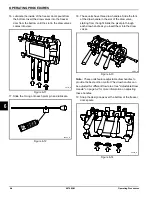

4. Remove the O-rings from the air tubes and air

orifices.

5. Return to the machine with a small amount of

cleaning solution. With the black bristle brush, brush

clean the rear shell bearings at the back of the

freezing cylinders.

6. Thoroughly brush clean all disassembled parts in the

cleaning solution. Make sure all lubricant and mix film

is removed. Take particular care to brush clean the

draw valve cores in the freezer door. Place all the

cleaned parts on a clean, dry surface to air dry

overnight.

7. Wipe clean all exterior surfaces of the machine.

Содержание C791

Страница 8: ...1 4 TO THE INSTALLER 087482 M To the Installer 1 ...

Страница 38: ...9 2 PARTS REPLACEMENT SCHEDULE 087482 M Parts Replacement Schedule 9 Notes ...

Страница 42: ...10 4 LIMITED WARRANTY ON EQUIPMENT 087482 M Limited Warranty on 10 Notes ...

Страница 46: ...11 4 LIMITED WARRANTY ON PARTS 087482 M Limited Warranty on Parts 11 Notes ...