Models 369/370/371

9

ENGLISH

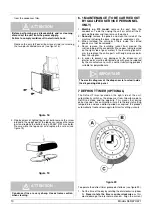

(see figure 12)

4 - Fit bowl gasket around its seat.

Note: the largest brim of gasket must face against the rear

wall (see figure 14).

figure 14

5 - Carefully insert the auger into the evaporator use caution

to prevent it from hitting the rear wall (see figure 15).

figure 15

6 - Install the outer spiral. Slide it over the evaporator until its

front notch engages with the exposed end of the auger

shaft (see figure 16).

figure 16

7 - Push the bowl toward the rear wall of the unit until it fits

snugly around the gasket and its front fastening hooks are

properly engaged (see figure 17).

figure 17

8 - On 369 MODEL install the lateral tray by reversing the

disassembly steps (see figure 6).

9 - Use fresh product to chase any remaining sanitizer from

the bottom of the bowl(s). Drain this solution. Do not rinse

out the machine.

5. 4 IN-PLACE SANITIZATION

The In-Place Sanitization prior to starting the machine may be

performed prior to starting the machine, if needed, this should

only be performed, in addition to the Disassembled Parts

Sanitization, but never in lieu of it.

1 - Prepare two gallons of a warm (45-60°C / 120-140 °F)

s a n i t i z i n g s o l u t i o n ( 1 0 0 P P M a v a i l a b l e c h l o r i n e

concentration or 1 spoon of sodium hypoclorite diluted with

half a gallon of water) according to your local Health

Codes and manufacturer’s specifications.

2 - Pour the solution into the bowl(s).

3 - Using a brush suitable for the purpose, wipe the solution

on all surfaces protruding above the solution-level and on

the underside of the top cover(s).

4 - Install the top cover(s) and operate the unit. Allow the

solution to agitate for about two minutes. Drain the solution

out of the bowl(s).

5 - Use fresh product to chase any remaining sanitizer from

the bottom of the bowl(s). Drain this solution. Do not rinse

out the machine.

6 ROUTINE MAINTENANCE

1 -

Daily:

inspect the machine for signs of product leaks past

seals and gaskets. If proper assembly does not stop leaks

around seals or gaskets, check for improper lubrication,

worn or damaged parts. Replace parts as needed.

2 -

Monthly on 369, 370 and 371 models:

remove the dust

ATTENTION

A damaged power cord must be replaced by an

authorized service agent. Failure to comply main result

in electric shock.

Содержание 369

Страница 12: ...OPERATOR PARTS IDENTIFICATION MODEL 369 370 371 2471_01 V 3 5 04I09...

Страница 16: ...046445 M 2471_01 R0 4 04I09...