Models 369/370/371

15

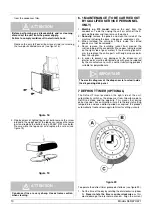

IMPORTANT: The display light bulb must be replaced with the factory authorized replacement bulb. Failure

to comply may result in component damage or severe personal injury due to broken glass.

Troubleshooting Guide

PROBLEM

PROBABLE CAUSE

REMEDY

1 - Product is too stiff.

a - Improper mixing of product.

b - Mix low condition.

c - Viscosity needs adjustment.

a - Carefully follow directions for mixing

product.

b - Add mix to mix hopper.

c - Adjust accordingly.

2 - Product is too soft.

a - Improper mixing of product.

b - Viscosity needs adjustment.

a - Carefully follow directions for mixing

product.

b - Adjust accordingly.

3 - No product is being dispensed.

a - Improper mixing of product.

b - Product frozen up in evaporator.

c - Beater shaft not rotating. Power switch

is not in the “I” position and the mix

refrigeration switch is not in the “I” or “II”

position.

a - Carefully follow directions for mixing

product.

b - Adjust viscosity accordingly.

c - The power switch must be in “I” and the

mix refrigeration switch in the “I” or “II”

position.

4 - The freezer will not operate with the

power switch in the “I” and the mix

refrigeration switch in the “I” or “II”

position.

a - The unit is unplugged.

b - Blown fuse, or the circuit braker is off.

c - The beater is off on high pressure cut

out (amber light is lit).

a - Check the plug at wall receptacle.

b - Replace the fuse or turn the braker on.

c - Clean the filter or provide adequate

ventilation.

5 - Excessive mix leakage from door

spout.

a - Improper or inadequate lubrication of

draw valve o-rings.

b - Wrong type of lubricant on draw valve

o-rings.

c - Worn or missing drawvalve o-rings.

a - Lubricate properly.

b - Use food grade lubricant (example:

Taylor lube).

c - Replace or install o-rings on draw valve.

Parts Replacement Schedule

PART DESCRIPTION

EVERY 3 MONTHS

EVERY 6 MONTHS

Outer Spiral Scraper Blade

Inspect & Replace as Necessary

Minimum

Rear Hopper Gasket

Inspect & Replace as Necessary

Draw Valve O-Ring

X

Содержание 369

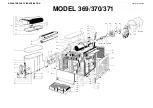

Страница 12: ...OPERATOR PARTS IDENTIFICATION MODEL 369 370 371 2471_01 V 3 5 04I09...

Страница 16: ...046445 M 2471_01 R0 4 04I09...