Turbomachinery Package Specification

Taurus

60 Compressor Set and Mechanical Drive

Table 3.

Typical Solar Gas Compressors

Maximum Pressure

Rating

Maximum Flow

Maximum Total Head

Compressor

Family

Number

of Stages

kPa

psig

m

3

/min

ft

3

/min

kJ/kg

ft-lb

f

/lb

m

For Gas Production Applications

C16 1-10

20

700

3000

50

1800

215

72,000

C33 1-12

15

510

2250

270

9500

325

108,000

C40 1-6

17

240

2500

255

9000

255

85,000

C50 1-5

10

350

1500

565

20,000

285

95,000

For Gas Pipeline Applications

C40 1-2

11

040

1600

270

9500

95

32,000

4.2.1 Impellers

Compressor impellers are designed to conservative stress levels. All impellers are

suitable for sour gas applications.

Each impeller, after machining, is proof tested to 115%

of its maximum mechanical speed.

4.2.2 Rotor

Assembly

The rotor assembly consists of stub shafts, impellers, and, if required, rotor spacers (to

maintain a constant bearing span) and a centerbolt. These components are individually

balanced and are rabbet-fit to each other for concentric alignment. Torque is transmitted

through dowel pins. The entire assembly is clamped together with the centerbolt. The

rotor assembly is easy to disassemble. The benefits from this type of construction are

two-fold. Impellers that can be used in a “restaged” rotor are easily salvaged and

downtime is minimized. Reusing old impellers, instead of purchasing new ones to match

new operating conditions, enhances the economic feasibility of restaging to maintain

optimum compressor performance and the lowest possible operating costs.

4.2.3 Casings

The pressure-containing outer casing of a compressor is an assembly of three

components: the suction and discharge end caps, which contain the bearing and seal

assemblies, and the centerbody, which holds the rotor and stator assemblies. This is

considered a vertically split “barrel” design. The end caps contain all the service ports for

oil and gas supply and discharge.

4.2.4 Compressor

Module

The compressor module includes the centrifugal compressor(s) mounted on a structural

steel matching base that, when bolted to the driver skid, forms a continuous base plate

on which all the required subsystems are installed.

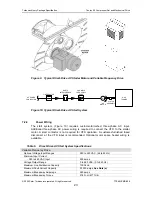

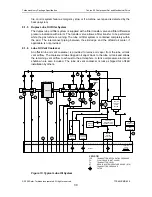

4.2.5

Lube Oil System

The gas turbine, gearbox (if required), and compressor modules have a common lube oil

system.

4.2.6

Compressor Dry Seal System

The dry seal system consists of the seal gas and separation gas systems. The seal

system maintains a barrier between the process gas and the compressor bearings. The

separation gas system maintains a barrier between the compressor bearing lube oil and

the dry gas seals.

© 2009 Solar Turbines Incorporated. All rights reserved.

TPS60CSMD/309

15