6

4.2.2 FLUSH CONTROL

Small debris passes through the gasket grabber and may get caught inside the nozzle. This trapped material will cause

poor stream quality, shortened reach and reduced flow. To remove this trapped debris the nozzle can be flushed as

follows; while still flowing water, turn the SHAPER counterclockwise past the full fog position (increased resistance will be

felt on the SHAPER as the nozzle goes into flush). This will open the nozzle allowing debris to pass through. Rotate the

SHAPER clockwise and out of flush to continue normal operation. During flush the nozzle reaction will decrease as the

pattern becomes wider and the pressure drops. The nozzle operator must be prepared for an increase of nozzle reaction

when returning the nozzle from the flush position to retain control of the nozzle.

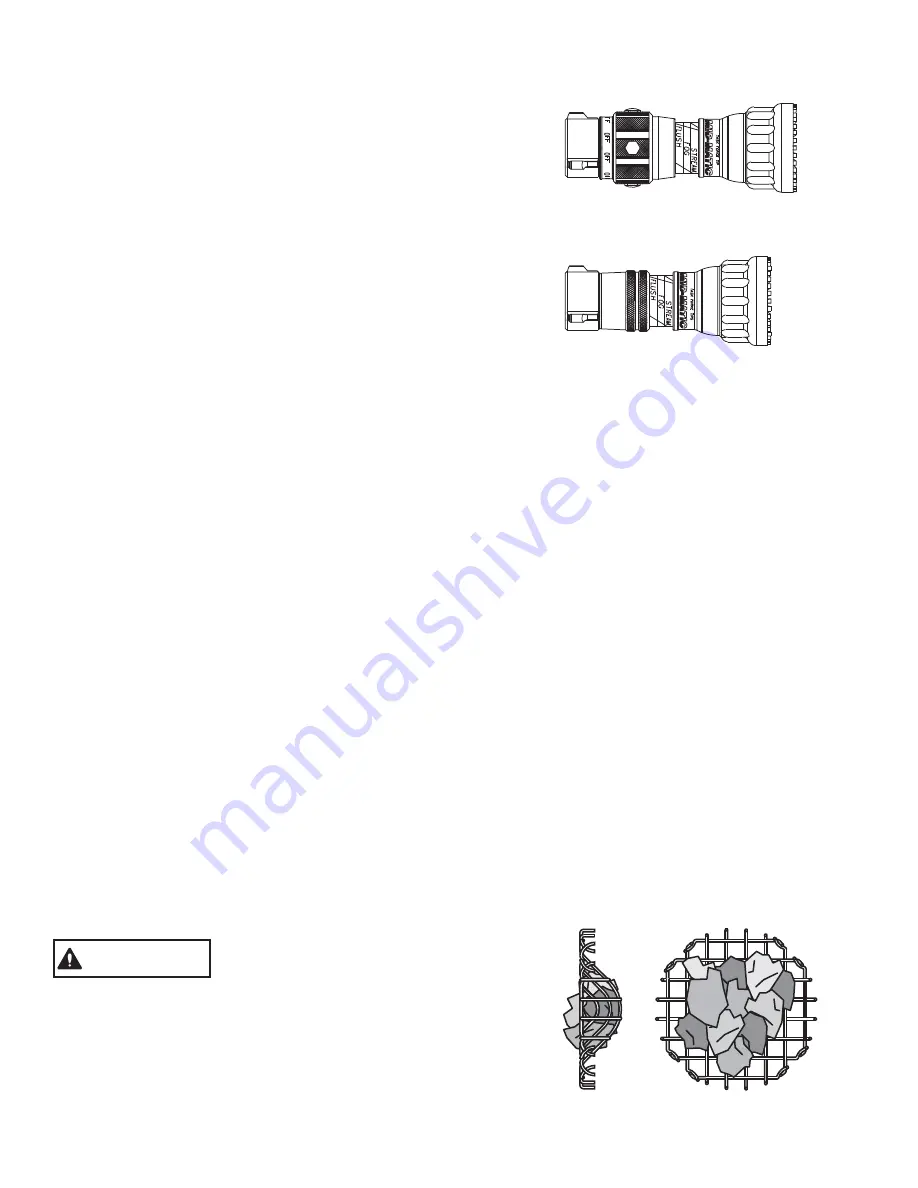

Large amounts of debris can reduce

the flow of the nozzle resulting in an

ineffective flow. In the event of a

blockage it may be necessary to

retreat to a safe area, uncouple

nozzle and remove debris.

FIGURE 3 - GASKET GRABBER

WARNING

4.2 PATTERN AND FLUSH CONTROL

4.2.1 PATTERN CONTROL

TFT's ULTIMATIC, MID-MATIC and HANDLINE have full pattern control from straight stream to wide fog. Turning the

STREAM SHAPER clockwise (as seen from the operating position behind the nozzle) moves the SHAPER to the straight

stream position. Turning the SHAPER counterclockwise will result in an increasingly wider pattern.

Since the stream trim point varies with the flow, the stream should be "trimmed" after changing the flow to obtain the

straightest and farthest reaching stream. To properly trim a stream, first open the pattern to a narrow fog. Then close the

stream to parallel to give maximum reach.

The nozzle reaction is greatest when the shaper is in the straight stream position. The nozzle operator must be prepared

for a change in reaction as the pattern is changed.

NOTE: Turning the shaper further forward will cause stream crossover

and reduce the effective reach of the nozzle.

4.1.2 TWIST SHUTTOFF

4.1.3 TIP ONLY NOZZLES

On models that use a twist flow control. The valve is opened or

closed by rotating the valve ring. Rotating the ring clockwise (as

seen from the operating position behind the nozzle) closes the

valve, while counterclockwise rotation opens it. Detents are

provided at four intermediate positions and the position of the

valve is shown by the exposed valve position label.

Tip only nozzles have NO shut off valve contained within the

nozzle and

be used with a separate ball valve attached to

the nozzle.

MUST

LIN-030 November 14, 2008 Rev 10

©Copyright Task Force Tips, Inc. 2002-2008