14

The Porta-Tile is designed for use with a

TARGET®

6"

Profile Wheel, such as P/N 621081 or 621082. (See Fig. 1)

Raise the Blade Guard (K). Remove the Blade Shaft

Nut (N) and Outer Flange (M). Remove the tile saw

blade if one has been installed.

Install the profile wheel onto the spindle shaft up against

the Inner Flange with the working surface to the out-

side.

Secure into place by reversing the Outer Flange (M)

and tightening the Blade Shaft Nut (N). Lower the Blade

Guard (K) back down over the profile wheel. Adjust Blade

Guard as needed to best center profile wheel in the

guard.

Locate the material for profiling:

1.

Set the edge of the part to be shaped parallel to

the wheel.

2.

Locate the material under the wheel. Pull the

Conveyor Cart (4) with the material from under the

wheel to set proper cutting height.

Your

Porta-Tile II

tile saw is factory assembled and aligned

prior to shipment to ensure accurate cuts when your saw is

delivered. However, since

TARGET®

cannot control rough

handling during shipping, it is suggested that the alignment

be checked. If the saw is found in need of adjustment, refer

to the appropriate section(s) below.

There are two basic alignment checks for the

Porta-Tile

and

any adjustments made must follow these procedures to

ensure that the unit functions freely. Always unplug the saw

before performing any alignments.

Adjustment tools required: Carpenters Square, a 1/2 wrench

and a 5/32 Hex Key wrench.

2.

Check the Parallel Alignment (See Figure 2)

*

The Conveyor Cart should travel parallel to the

plane of the blade. The Blade should not set at an

angle to the cut line through the tile.

*

Place a square rule against the backstop, lightly in

contact with the blade. The blade surface should

be parallel to the square; i.e., no gap between the

blade and the square at either the front or back

edge of the blade. (It is important that the blade

be flat. To check, slowly rotate the blade by hand

with the square lightly contacting it.) Next, holding

the square firmly, traverse the cart fore and aft.

The blade should remain parallel to the square,

staying slightly in contact with it throughout its full

travel. If the blade does not stay in contact with

the square, the Parallel alignment must be per-

formed.

Parallel Alignment

*

The parallel tracking of the Cart can be adjusted

by squaring the Rails (R) to the Frame which hold

the Cutting Head Assembly. It is helpful to align

one rail first and then use the cart to set the sec-

ond rail parallel to the first. The holes in the rails

are larger enough to accommodate any adjustment

needed.

*

A good practice is to align the INNER RAIL first.

Loosen the eight (8) 5/16"-18 capscrews (1/2"

wrench) locating the two (2) Rails (R) so that both

rails are free to move. Move the end(s) of rail until

the square is flush with the blade as described

above. Tighten the fasteners of this rail and re-

check the alignment. Once alignment has been

made, move the cart fore and aft to locate the

second rail parallel to the first. Tighten the remain-

ing fasteners.

1

.

Check the Blade in Slot Alignment

*

The blade should be centered in the conveyor cart

slot.

*

Set-up your saw as described above and move the

conveyor cart back and forth from the front to the

rear of the pan. If the blade contacts either side of

the slot, the Cutting Head Location Adjustment must

be performed.

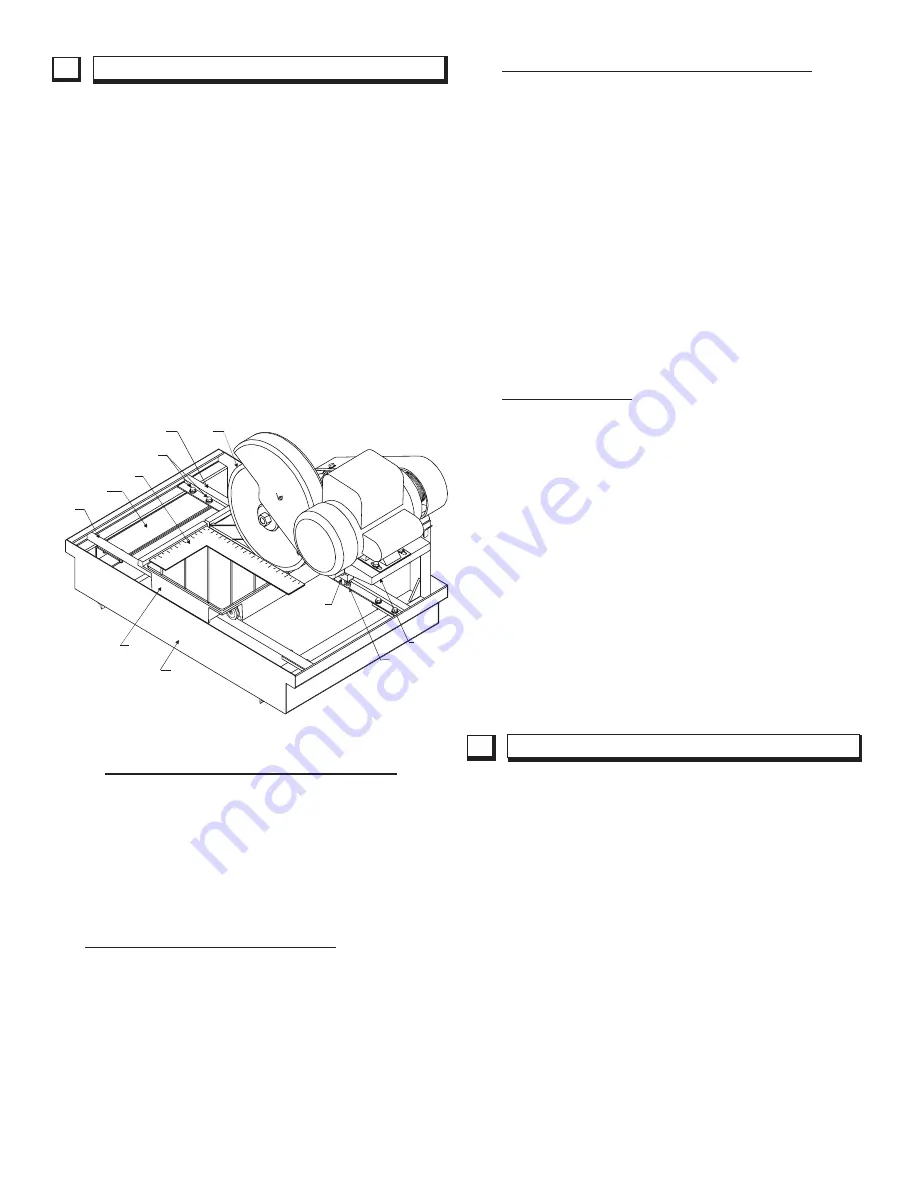

Cutting Head Location Adjustment (See Figure 1)

*

The Cutting Head Assembly is located along the

Pivot Bar (A). Using a 1/2 wrench, loosen the four

5/16 capscrews holding the two Bearing Caps (B).

Also, with a 5/32 Hex Key, loosen the two Set Col-

lars (S). Move both the Set Collars and Head As-

sembly along the bar until the blade is centered in

the slot. Re-tighten the Set Collars and four 5/16

capscrews.

FIGURE 2

7

ALIGNMENT PROCEDURES

8

PROFILE WHEEL SET-UP AND USE

5/16”-18

FASTENERS

B

BEARING CAP

(8) 5/16”-18

FASTENERS

R - RAIL

INNER

SQUARE

R

RAIL

CART

PAN

MOTOR

BASE

RAIL

SUPPORT

BLADE

Содержание PORTA-TILE II

Страница 17: ...17 NOTES ...

Страница 30: ...30 Diagram 2 Wiring Diagram 169422 ...

Страница 31: ...31 Diagram 3 Wiring Diagram 000503 ...

Страница 32: ...32 NOTES ...