20

20/03/2015

Tanco Autowrap 404

Operators manual

9.0

PERIODIC MAINTENANCE.

9.1

BEARINGS.

All ball-bearings are packed with grease, and do not need any more maintenance.

9.2

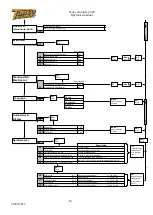

DISPENSER.

If the machine is in daily use, the guiding sleeves at the pre-stretcher should be oiled once a

week or when needed. Sprockets and bearings on the pre-stretcher should also be oiled when

needed.

9.3

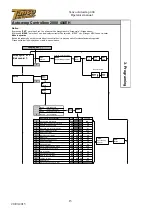

CHAINS.

Oil the chains at regular intervals. Take them off once a year for cleaning and oiling. Soak the

chains in oil for 2-3 days and afterwards hang up for 10-12 hours to drain.

After some use, the chain from the motor to the turntable has to be adjusted. Unlock the nuts on

the motor bracket, and tighten up the adjustment.

DO NOT TIGHT TOO MUCH, CAUSE THIS WILL INCREASE THE WEARING

OF

THE BEARINGS.

The chains on the square rollers also have to be adjusted. There is one chain tensioners on each

side.

9.4

GEAR.

The shaft in the turntable’s center (below the cover) must be greased when required.

9.5

HYDRAULIC CYLINDERS.

Make sure that the hydraulic cylinder is closed when storing the machine.

9.6

CLEANING.

The machine should be cleaned and oiled regularly and by the end of the wrapping season.

NB!

When using a steamer, you need to be careful with the electric equipment and bearings.

Keep the counter protected from rain or water.

9.7

QUICK COUPLERS.

Be careful to keep the quick couplers clean and apply the dust caps after use. The connecting

hoses are to be placed in the holders, on the side of the machine when not in use.

9.8

STORAGE.

The machine should be parked on a dry place during the closed season.