Chapter C

Chapter C

Maintenance Mode

149

W301-0411E

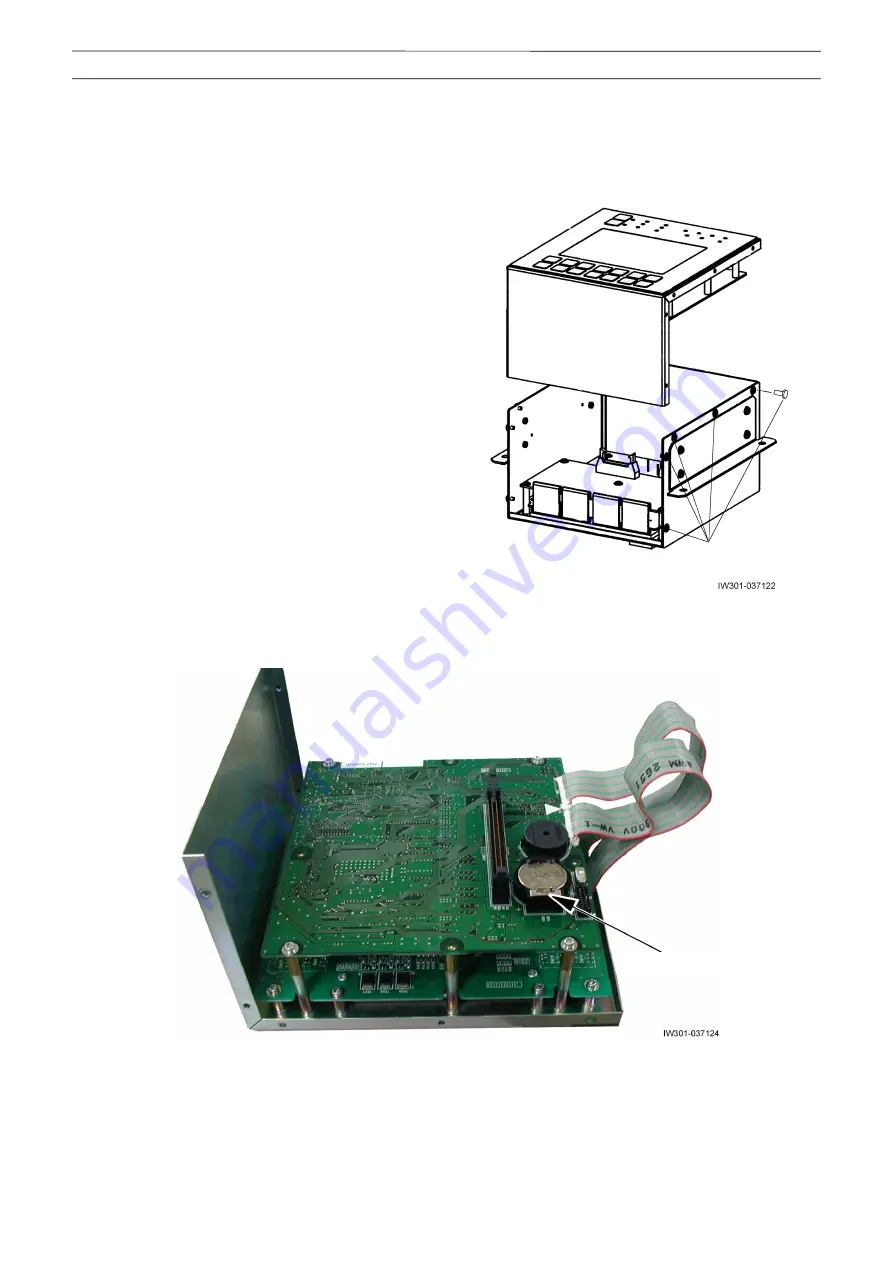

6.3 Replacing the Clock Battery

[NOTICE]

When the clock battery is worn out, the adjustment

values, error codes and driving history cannot be

backed up (saving data at power OFF).

Also, when the error code or overload history is

recorded in the AML, an accurate date and time

cannot be recorded.

One built-in clock batteries is on CPU board.

Battery type: CR2450

When removing the battery, remove while holding

the battery upper (positive side) because the

battery may pop up.

The built-in clock battery longevity is usually about

10 years.

If the built-in clock batteries are wasted, replace

them according to the following procedures.

(Procedure)

1. Remove the upper case (CPU board) from the

AML main unit.

2. Remove the battery from the battery holder on CPU board (press the protrusion indicated by an arrow).

3. Install a new battery to the CPU board.

The battery positive side must be faced up.

4. Mount the upper case (CPU board) to the AML main unit.

Screw (a)

Press the protrusion

Содержание AML-C

Страница 1: ...W301 0411E 01 Load Moment Indicator AML C Model...

Страница 8: ...Foreword vii W301 0411E 5 Crane Performance...

Страница 16: ...Chapter A Chapter A Components of AML System 6 W301 0411E 1 2 2 LED Display...

Страница 161: ...Chapter C Chapter C Maintenance Mode 147 W301 0411E Extract the contact in accordance with following procedure...