96

Operation HAFC101 and 201:

The Hydro Air Fan Control is an interface

between the thermostat and air handler. It

also has an isolated end switch to start the

boiler and/or pump. When the thermostat

calls for heat, the Fan Control energizes the

end switch relay and allows the fan to operate

at low speed when the water is above the

optional aquastat setting. When the thermo-

stat calls for cooling, the Fan Control energizes

the condenser and operates on high speed.

Additional HAFC201 Operations:

Selectable one, three or four minute delay on

fan operation in heating mode. Selectable

pump exercise activates circulator but does

not enable boiler contacts. Two minutes every

24 hours minimizes the chance of bacteria

build-up in an open loop system. Thirty sec-

onds every two weeks minimizes seasonal

start-up problems generally associated with

harsh water conditions. Optional aquastat or

thermostat can be connected to Freeze

Protection TT terminals to reduce the chance

of pipes freezing by energizing the pump dry

contacts (boiler contacts not activated.)

Switch Settings (HAFC201):

1

1 minute on fan delay, in heating mode

2

3 minute on fan delay, in heating mode

1&2

4 minute on fan delay, in heating mode

3

Pump dry contact activated for 2 min-

utes every 24 hours (boiler contacts not

activated)

4

Pump dry contacts activated for 30 sec-

onds every two weeks (boiler contacts

not activated)

External Diagnostics:

The external lights show full functionality of

the Hydro Air Fan Control. The green light

should always be on, indicating that power is

connected. Red lights indicate fan operation

for heating and cooling modes.

Warning:

Wiring connections must be made in accordance with

all applicable electrical codes. Use copper wire only.

Failure to follow this instruction can result in personal

injury or death and/or property damage. 10-18 gauge

wire recommended for 120 VAC connections with

9 in.lbs. max torque, 12-22 gauge wire for thermostat

connections with 9 in.lbs. max torque, and 12-22 gauge

wire for 24 VAC source with 5 in.lbs. max torque.

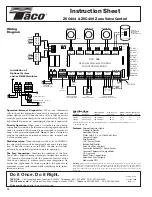

M

Fan

Relay

Line

24 V

A

C

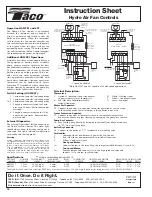

1 Speed Air Handler*

THERMOSTAT

Optional Power Wire

to Thermostat

that Requires 24VAC

To: Optional

Aquastat on

Return Line of

Hydro Coil

Dry Contacts

To: “T T” on

Boiler or

Switching

Relay

Power On

Call for Heat

Fan, Cooling

Fan, Heating

Outdoor

Condenser

Unit

TT

BOILER

AIR HANDLER

G G

XX C R Y

C RG

Y

W

THERMOSTAT

AQUASTATS

HAFC201

HYDRO AIR FAN CONTROL

T

T

WATER COIL FREEZE PR

To: Optional Aquastat

or Thermostat to sense

low ambient

temperature

Hot

Neutral

Circulator

X

X

PUMP

5 AMP 1/6 HP RATED

DRY CONTACTS

1 MIN ON DELAY - FAN

3 MIN ON DELAY - FAN

2 MIN @ 24 HR - PUMP

30 SEC @ 2 WK - PUMP

OFF ON

Jumper

(or to “T T” on

switching relay)

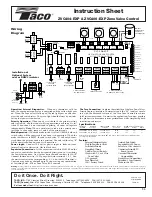

2 Speed Air Handler*

THERMOSTAT

Optional Power Wire

to Thermostat

that Requires 24VAC

To: Aquastat on

Return Line of

Hydro Coil

Dry Contacts

To: “T T” on Boiler

or Switching Relay

Power On

Call for Heat

Fan, Cooling

Fan, Heating

Outdoor

Condenser

Unit

T T

BOILER

AIR HANDLER

G G

XX C R Y

C RG

Y

T

W

THERMOSTAT

AQUASTAT

HAFC101

HYDRO AIR FAN CONTROL

M

Low

High

Line

24 V

A

C

Fan

Relays

Terminal Description:

Thermostat:

C

Optional: Common side of transformer

W

White - Heating signal

to power some styles of thermostats

Y

Yellow - Condenser signal

R

Red - Hot side of transformer used to

G

Green - Fan signal

switch all functions

Water Coil Aquastat:

TT

Connect to aquastat at air handler to control operation of the fan when

in the heating mode. Install a jumper if the aquastat is not used

Freeze Protection Aquastat:

TT

Connect to aquastat or thermostat to sense low ambient temperature.

Reduces the chance of pipes freezing by energizing the pump dry contacts.

Pump Dry Contacts:

XX May switch pump directly by bringing in external line voltage or connect

to “T T” on a switching relay.

Boiler Dry Contacts:

XX Connect to the boiler or “T T” terminals on a switching relay.

Air Handler:

C

Common side of transformer to power the Fan Control

R

Red - Hot side of transformer used to switch all functions

Y

Yellow - Condenser signal

One Speed Motor:

G

low

Connect the fan to the relay. Keep the jumper installed between G

high

and G

low

.

Two Speed Motor:

G

high

Remove jumper and connect G

high

to the high speed fan relay and

connect G

low

to the low speed fan relay.

Specifications: **

Model

n

u

m

ber cha

n

ged fro

m

SR501-F

PRODUCT

NUMBER

POW

ER

INPUT

MAXIMUM

RELAY

THERMOSTAT

SINGLE PHAZE MOTOR

DIMENSIONS OF ENCLOSURE

NUMBER

OF ZONES

VOLTAGE

COMBINED LOAD

TYPE

CURRENT

RATING (RELAY)

WIDTH

HEIGHT

DEPTH

HAFC101**

1 Zo

n

e

24 VAC I

n

put

5 a

m

ps

DPDT

.18

1/6 HP(5A) @120VAC

4 1/4

"

5 1/4

"

2 3/4

"

HAFC201

••

1 Zo

n

e

24 VAC I

n

put

5 a

m

ps

DPDT

.18

1/6 HP(5A) @120VAC

4 1/4

"

5 1/4

"

2 3/4

"

The Hydro Air Fa

n

Co

n

trols are relay type DPDT, have a ther

m

ostat curre

n

t of .18 a

n

d a si

n

gle phase

m

otor rati

n

g per zo

n

e of 1/6 HP (5A) @ 120 VAC.

Instruction Sheet

Hydro Air Fan Controls

Printed in USA

Copyright 1999

TACO, Inc.

* Both HAFC101 and 201 capable of 1 and 2 speed applications

Do it Once. Do it Right.

TACO, INC.

, 1160 Cranston Street, Cranston, RI 02920

Telephone: (401) 942-8000

FAX: (401) 942-2360.

TACO (Canada), Ltd.

, 6180 Ordan Drive, Mississauga, Ontario L5T 2B3.

Telephone: 905/564-9422.

FAX: 905/564-9436.

Visit our web site at:

http://www.taco-hvac.com

Printed in USA

Copyright 1999

TACO, Inc.