Discovery TGA™ Getting Started Guide

Page 31

Connecting the Discovery TGA to the Controller

To connect the TGA system, you will need access to the Discovery TGA instrument’s back panel.

NOTE

: Connect all cables before connecting the power cord to an outlet.

CAUTION: Whenever plugging or unplugging power cords, handle them by the plugs, not by the

cords.

MISE EN GARDE: Chaque fois que vous branchez ou débranchez les cordons d'alimentation,

tenez-les par les fiches et non par les cordons.

The Discovery TGA back panel has fifteen ports; the table below provides a description of the function of

each port.

WARNING: Protect power and communications cable paths. Do not create tripping hazards by

laying the cables across access ways.

AVERTISSEMENT: Protégez les chemins de câble électriques et de câbles de télécommunica-

tion. Ne créez pas de risques de déclenchement en posant des câbles sur les voies d'accès.

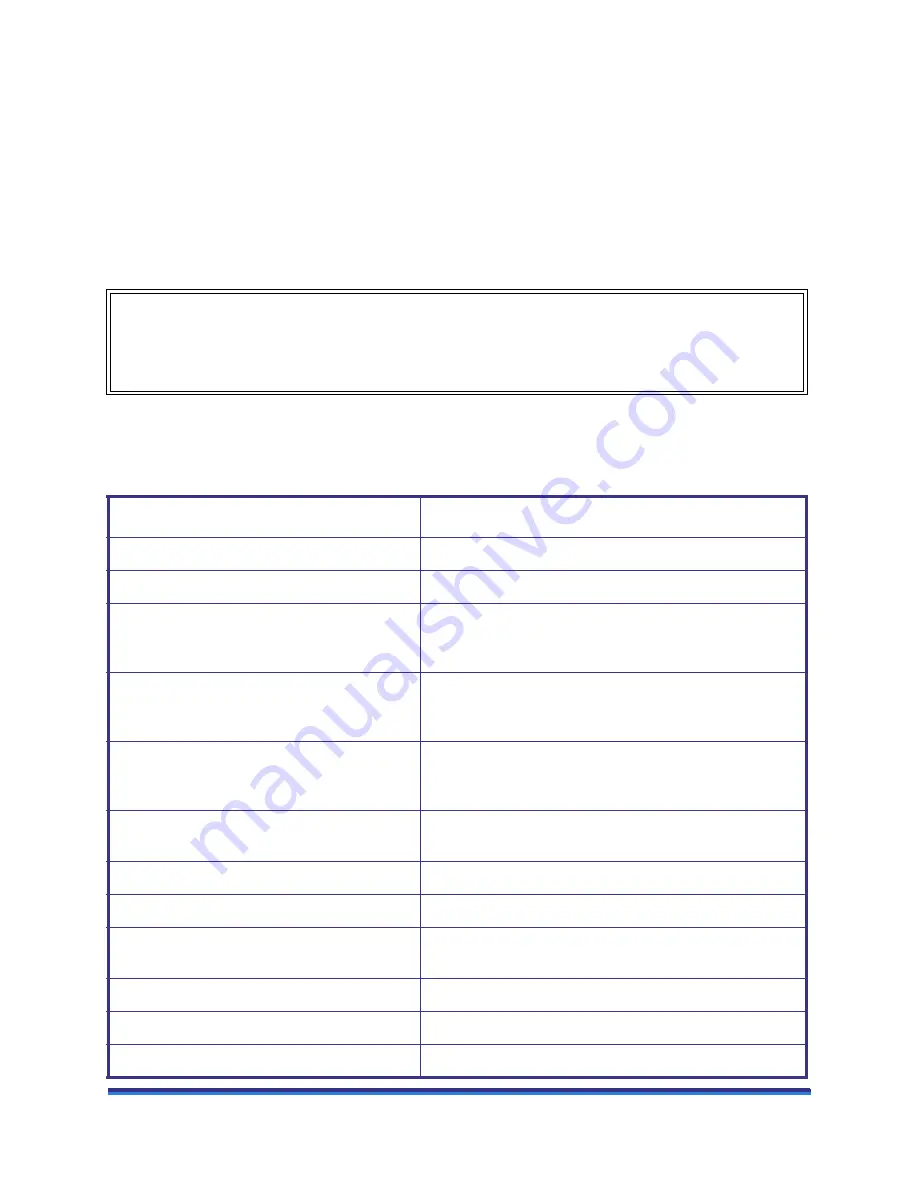

Table 6:

Discovery TGA Back Panel

Port

Function

Power Entry Module (power cord and switch)

Provides power and protective earthing to the system.

Fuses

Provides overcurrent protection.

REACTIVE GAS

Port for introducing an additional gas directly into the

vicinity of the sample and reference. External flow regulation

required. Maximum pressure is 140 kPa gauge (20 psig).

GAS 1

Gas inlet port controlled by the gas delivery module. Used for

the sample and balance purge gas. Maximum pressure is

140 kPa gauge (20 psig).

GAS 2

Gas inlet port controlled by the gas delivery module. Used for

the secondary sample purge gas. Maximum pressure is

140 kPa gauge (20 psig).

COOLING GAS

Provides the furnace with air for post-run cooling. Maximum

pressure is 140 kPa gauge (20 psig).

RS-232 Port

Provides communications with external accessories.

CAN Communications Port

Provides communications with external accessories.

Ethernet

Provides communication between controller and TGA

instrument.

USB 2.0 Port

Provides communications with external accessories.

Micro USB 2.0 Port

Provides communications for external accessories.

SD memory card slot

For TA Instruments Service use only.